335345435

Sep . 05, 2024 04:20 Back to list

Premium Fuel Hose Supplier | Durable & Reliable Fuel Hoses

A Glimpse into the Fuel Hose Manufacturing Industry

The fuel hose manufacturing industry plays a crucial role in supporting the transportation and energy sectors. Fuel hoses are essential components that ensure the safe and efficient transfer of fuels, including gasoline, diesel, and other petroleum products, between vehicles, storage tanks, and dispensing equipment.

Overview of Fuel Hoses

Fuel hoses are specialized tubes designed to withstand the corrosive properties of fuel, high pressures, and varying temperatures. The materials used in their construction often include rubber, thermoplastic, and other synthetic compounds that provide durability and resistance to environmental stressors. These hoses come in various sizes and configurations to meet the diverse requirements of different applications.

Manufacturing Process

The manufacturing process for fuel hoses involves several key steps, including material selection, compounding, extrusion, and curing. High-quality raw materials are chosen based on their properties and suitability for fuel applications. Manufacturers then create rubber compounds by blending various additives to enhance performance characteristics such as flexibility, resistance to temperature fluctuations, and longevity.

Extrusion is the next step, where the rubber is forced through a mold to create the desired hose shape. This is followed by curing, a chemical process that solidifies the material, ensuring it retains its form and strength under pressure. Quality control is paramount throughout this process; manufacturers conduct rigorous testing to ensure that each hose meets industry standards for safety and performance.

fuel hose factory

Industry Standards and Regulations

The fuel hose industry is governed by various international and national standards, ensuring that products are safe for consumer use. Organizations such as the American Society for Testing and Materials (ASTM) and the Society of Automotive Engineers (SAE) outline specific requirements regarding hose construction, material performance, and testing methods. Compliance with these standards is crucial for manufacturers to ensure that their products can withstand the rigors of fuel transportation without leaking or failing.

Market Trends and Innovations

With the global shift towards sustainability, the fuel hose manufacturing industry is witnessing significant changes. There is a growing demand for hoses that can handle biofuels and alternative fuels, which require different material properties compared to traditional petroleum-based fuels. Manufacturers are investing in research and development to create hoses that meet these new requirements while also being eco-friendly.

Additionally, advancements in technology, such as the introduction of automated production processes and the use of advanced materials, are revolutionizing the industry. These innovations not only enhance product quality but also improve operational efficiency, allowing manufacturers to respond swiftly to market demands.

Conclusion

The fuel hose manufacturing industry is a vital link in the supply chain that supports the global economy. As the industry continues to evolve with advancements in technology and material science, manufacturers must stay attuned to changing regulations and customer needs. By prioritizing safety, quality, and innovation, the fuel hose industry will continue to contribute significantly to the efficient movement of fuel and energy around the world.

-

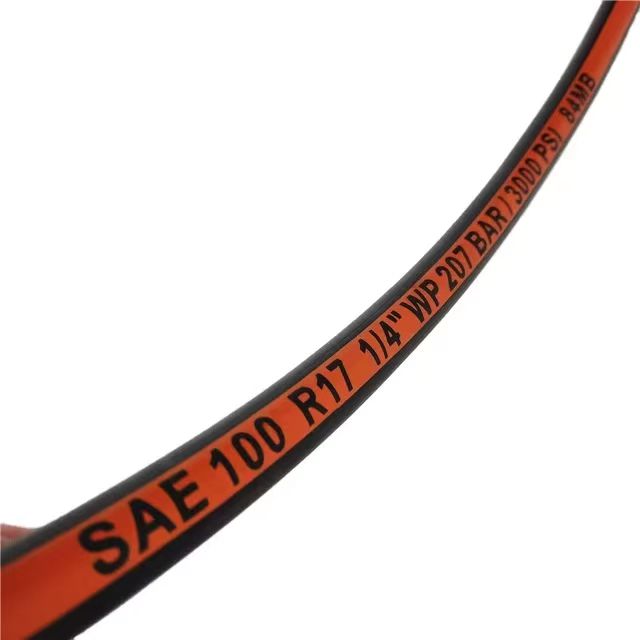

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025