335345435

Dec . 05, 2024 01:56 Back to list

Top Manufacturers of Four Wire Spiral High Pressure Hydraulic Hoses wereldwijd

Understanding Four Wire Spiral High Pressure Hydraulic Hoses Manufacturers and Applications

In the realm of hydraulic systems, the role of hoses is crucial. These hoses are responsible for transmitting fluid power in various industrial applications, ensuring that machinery functions smoothly and efficiently. Among the different types of hydraulic hoses, four wire spiral high pressure hydraulic hoses stand out for their durability and reliability, especially in high-stress environments. This article delves into the characteristics of these hoses, their applications, and the manufacturers who produce them.

What Are Four Wire Spiral High Pressure Hydraulic Hoses?

Four wire spiral hydraulic hoses are designed to withstand extreme pressures while ensuring flexibility and longevity. They are constructed with four layers of steel wire spiraled around the hose, which provides exceptional strength and prevents rupture or failure even under high pressure. This design not only enhances the hose's pressure rating but also improves its performance in dynamic applications where movement is prevalent.

Typically, these hoses can operate at pressures exceeding 4000 PSI, making them suitable for heavy-duty applications in industries such as construction, mining, agriculture, and manufacturing. Additionally, the inner tube is often made from resilient materials like synthetic rubber, which is resistant to hydraulic fluids, abrasion, and weathering, further extending the hose's lifespan.

Key Features and Benefits

1. High Pressure Resistance The primary advantage of a four wire spiral design is its ability to handle high pressures, reducing the risk of failure during operation. 2. Flexibility Despite their robust construction, these hoses maintain a degree of flexibility, which is essential for applications where movement and bending are necessary.

3. Durability Designed for long service life, these hoses resist wear, tear, and environmental factors, ensuring consistent performance.

4. Versatility They can be used with various fluids and in differing conditions, making them suitable for a wide range of applications.

Applications of Four Wire Spiral Hydraulic Hoses

The versatility of four wire spiral hydraulic hoses enables their use across multiple sectors

. Some common applications include- Construction Equipment Heavy machinery such as excavators and bulldozers rely on these hoses to operate hydraulic systems, lifting heavy loads and performing various tasks.

four wire spiral high pressure hydraulic hose manufacturers

- Mining Operations In the mining industry, these hoses are used in drilling and excavation equipment, where high pressure is essential for performance.

- Agriculture Tractors and other agricultural machinery utilize these hoses to operate functions such as lifting and plowing, ensuring productivity in the field.

- Manufacturing Processes Many industrial applications require the precision and power that these hoses deliver, particularly in automotive and assembly lines.

Manufacturers of Four Wire Spiral Hydraulic Hoses

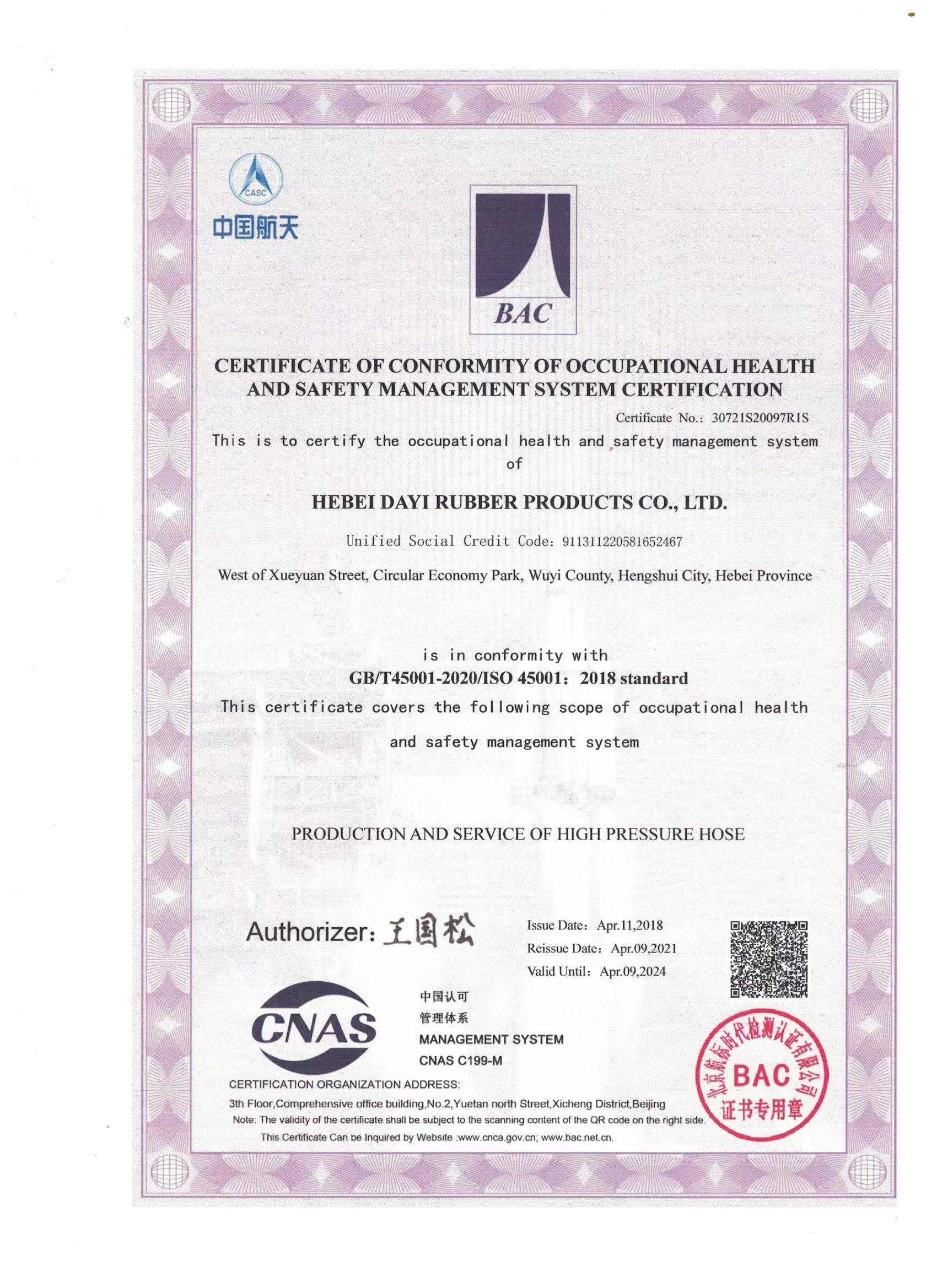

Given their importance in various sectors, several manufacturers specialize in producing high-quality four wire spiral hydraulic hoses. When selecting a manufacturer, it's vital to consider factors such as quality certifications, material standards, and technological capabilities. Leading manufacturers often invest in advanced manufacturing processes, ensuring that their products meet international quality standards.

Some of the prominent manufacturers in this field include

- Parker Hannifin Renowned for its innovation and quality, Parker provides a wide range of hydraulic hoses, including four wire spiral options that cater to high-pressure applications.

- Eaton Corporation Another industry leader, Eaton offers efficient hydraulic solutions, focusing on durability and performance to meet the rigorous demands of various sectors.

- Gates Corporation Gates is known for its commitment to developing high-performance hoses that offer reliability and safety for hydraulic systems.

- Continental AG With a strong presence in the automotive and industrial sectors, Continental manufactures hoses that ensure optimal performance under pressure.

Conclusion

In summary, four wire spiral high pressure hydraulic hoses are integral components in many industries, providing the strength and flexibility necessary to operate heavy machinery and equipment under demanding conditions. The choice of a reliable manufacturer is essential to ensure the quality and performance of these hoses. As industries continue to evolve, the demand for durable and efficient hydraulic solutions will undoubtedly expand, highlighting the importance of these specialized hoses. Whether in construction, agriculture, or manufacturing, the role of four wire spiral hydraulic hoses remains pivotal in driving operational efficiency and effectiveness.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025