335345435

Nov . 22, 2024 20:32 Back to list

flexible ptfe hose

Understanding Flexible PTFE Hoses Features and Applications

Flexible PTFE (Polytetrafluoroethylene) hoses have emerged as a vital component in various industrial applications, thanks to their remarkable chemical resistance, high-temperature tolerance, and flexibility. These hoses are fabricated from PTFE, a synthetic fluoropolymer, which is well-known for its non-reactive and non-stick properties. This article delves into the characteristics, advantages, manufacturing processes, and typical applications of flexible PTFE hoses.

Key Features of Flexible PTFE Hoses

1. Chemical Resistance One of the primary advantages of PTFE hoses is their unparalleled resistance to a wide range of chemicals, including corrosive substances such as acids and bases. This feature makes them indispensable in industries where harsh chemicals are handled, and safety is paramount.

2. Temperature Tolerance Flexible PTFE hoses can withstand extreme temperatures, typically ranging from -200°C to +260°C (-328°F to +500°F). This temperature resilience allows them to be used in demanding environments, from industrial processes to laboratory settings.

3. Flexibility and Versatility Despite being durable and resistant to various chemical agents, PTFE hoses maintain excellent flexibility. This adaptability enables them to be easily installed in tight spaces or around obstacles, making them a preferred choice in complex piping systems.

4. Non-Stick Surface As PTFE is known for its non-stick characteristics, flexible PTFE hoses do not allow substances to adhere to their internal surfaces. This property not only enhances performance but also simplifies cleaning processes, thereby reducing maintenance time and costs.

5. Low Friction The low coefficient of friction associated with PTFE hoses contributes to efficient fluid flow, minimizing energy consumption and wear on pumping systems.

Manufacturing Processes

The manufacturing of flexible PTFE hoses generally involves several stages to ensure that the final product meets stringent quality and performance standards. The process typically starts with the extrusion of PTFE tubes, which are then sintered to enhance their mechanical properties.

flexible ptfe hose

In many applications, these tubes are reinforced—commonly using stainless steel braiding or other materials—to increase burst pressure resistance and improve durability. After reinforcement, the hoses undergo processes such as cutting, assembly, and testing to ensure they meet the specified requirements.

Typical Applications

Flexible PTFE hoses are widely used across various industries due to their unique properties. Some notable applications include

- Pharmaceuticals In pharmaceutical manufacturing, strict cleanliness and safety standards are vital. Flexible PTFE hoses are ideal for transporting chemicals, APIs (Active Pharmaceutical Ingredients), and other substances that require stringent cleanliness.

- Food and Beverage The food industry demands non-contaminating materials for food processing and handling. PTFE hoses can withstand cleaning agents and high temperatures, making them suitable for food and beverage applications.

- Chemical Processing Given their resistance to corrosive chemicals, PTFE hoses are extensively used in chemical plants for the transport of acids, alkalis, and solvents while minimizing the risk of leaks and spills.

- Aerospace and Automotive In the aerospace and automotive sectors, PTFE hoses are utilized in fuel lines, lubricating systems, and hydraulic systems due to their high temperature and pressure tolerances.

- Laboratories Many laboratory applications require the transfer of various chemicals. Flexible PTFE hoses are often chosen for their ability to handle a range of chemical properties while remaining safe and effective.

Conclusion

Flexible PTFE hoses are indispensable in a plethora of industrial applications, offering unparalleled chemical resistance, temperature tolerance, flexibility, and low maintenance needs. Their unique properties render them a reliable choice for industries where safety and performance are critical. As technology continues to evolve, the development of advanced PTFE hose designs will likely enhance their efficiency and applicability, further cementing their place in modern industrial operations. Whether in pharmaceuticals, food processing, or chemical manufacturing, flexible PTFE hoses are a testament to innovation in material science and engineering, providing solutions that ensure safety and performance in demanding environments.

-

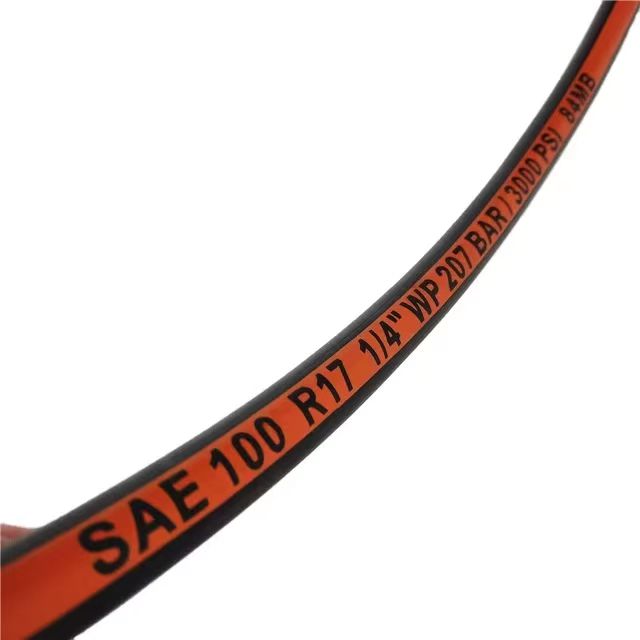

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025