335345435

Aug . 06, 2024 14:54 Back to list

Exploring the Versatility and Applications of High-Quality Rubber Hoses in China

An Overview of China’s Rubber Hose Industry

The rubber hose industry in China is an integral part of the country’s manufacturing landscape, serving multiple sectors including construction, automotive, agriculture, and industrial applications. With its robust production capabilities, advanced technology, and a wide range of products, China has established itself as one of the leading producers of rubber hoses globally.

Historical Context

China's rubber hose manufacturing dates back several decades, with significant growth observed in the last twenty years. The country’s entry into the World Trade Organization (WTO) in 2001 accelerated its industrial capabilities, allowing it to access global markets and scale production. This expansion was largely facilitated by government support, which provided incentives for investment in manufacturing technologies and infrastructure.

Types of Rubber Hoses

The rubber hose market in China is diverse, catering to various industries with specific needs. The most common types of rubber hoses produced include

1. Industrial Hoses These are designed for use in factories and warehouses, often employed for transporting liquids, gases, and other materials. Industrial hoses vary widely in size and specifications based on their intended use, such as conveying chemicals or hot water.

2. Automotive Hoses A significant segment of the market, automotive hoses are critical for the functionality of vehicles. They include radiator hoses, fuel hoses, and air conditioning hoses, all engineered to withstand high temperatures and pressures.

3. Agricultural Hoses These hoses are specially designed for farming applications, used for irrigation, drainage, and the transport of fertilizers and pesticides. Their durability and flexibility are crucial for efficient agricultural operations.

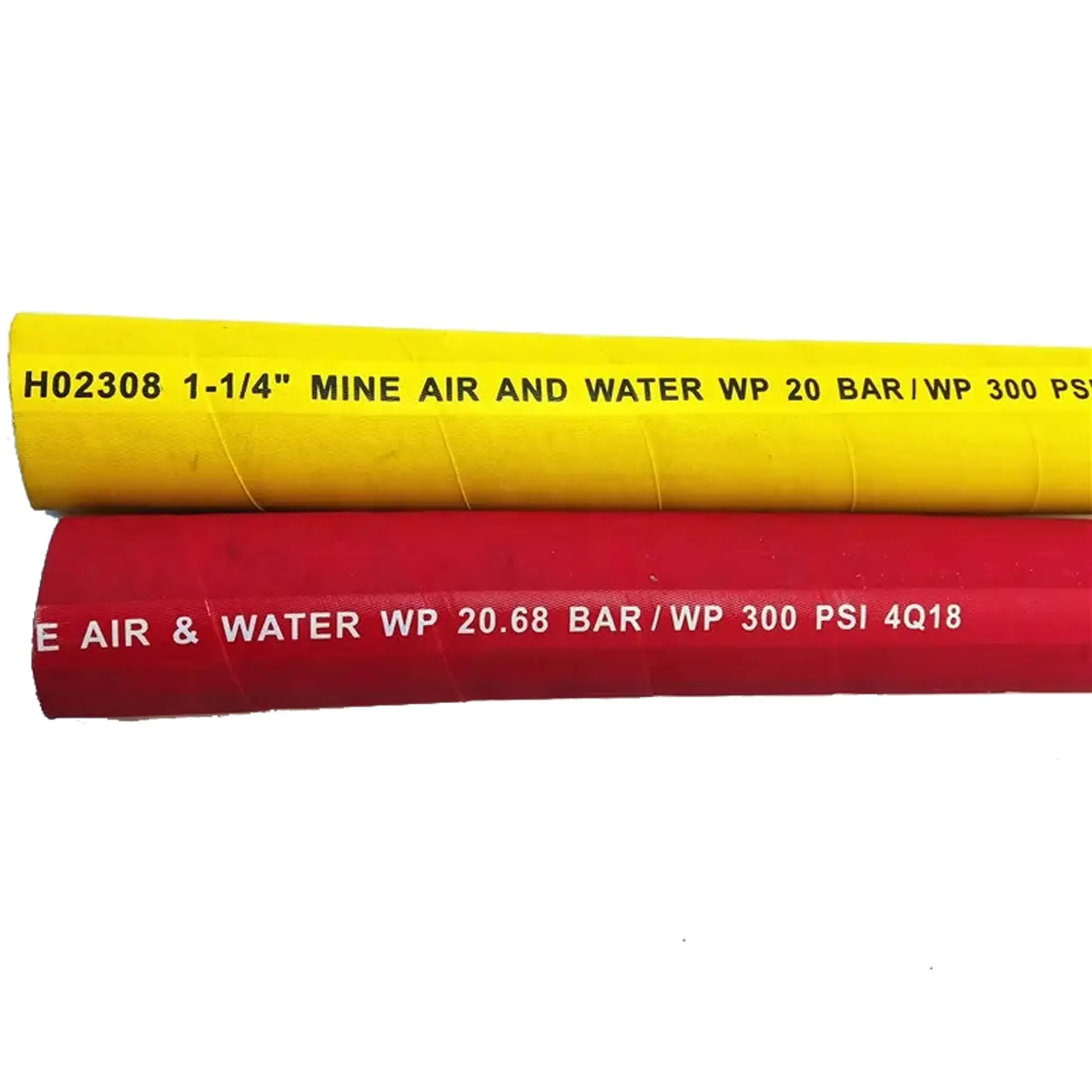

china rubber hose

4. Food and Beverage Hoses For industries involving food production and processing, compliance with health standards is paramount. Food-grade rubber hoses are manufactured to meet strict regulations, ensuring safety in the transport of consumable goods.

Manufacturing Techniques and Innovations

Chinese manufacturers employ a variety of advanced techniques in the production of rubber hoses. Many companies have adopted automated processes and state-of-the-art machinery, allowing for greater efficiency and precision. Innovations such as advanced compounding materials and blend formulations enhance the performance and durability of rubber hoses, contributing to their reliability in demanding applications.

Moreover, research and development play a pivotal role in keeping Chinese rubber hose products competitive. Manufacturers invest heavily in creating new formulations that improve resistance to factors such as abrasion, chemicals, UV light, and extreme temperatures. This commitment to innovation has enabled China to produce hoses that not only meet local demands but also comply with international quality standards.

Challenges and Opportunities

Despite its strengths, the rubber hose industry in China faces several challenges. Environmental regulations are becoming increasingly stringent, prompting manufacturers to adapt their processes to minimize waste and emissions. Additionally, competition from other global players necessitates constant innovation and cost management.

On the other hand, the growing demand for high-quality rubber hoses, driven by industrial expansion and infrastructure development, presents significant opportunities. As global economies recover and expand, the need for dependable rubber hoses will only increase, positioning China favorably as a key supplier.

Conclusion

In conclusion, the rubber hose industry in China plays a vital role in the global supply chain. With a rich history of development, a wide range of products, and a commitment to innovation, China is well-equipped to meet the growing demands of various industries. As challenges arise, the industry's adaptability and resilience will be essential in maintaining its competitive edge and ensuring sustainable growth for the future.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025