335345435

Aug . 06, 2024 08:21 Back to list

Exploring the Innovations and Benefits of High-Pressure Hose Technology in Various Industries

The Versatile World of Hyperpress Hose Revolutionizing Fluid Transfer

The world of industrial applications is continually evolving, and at the heart of this transformation is the innovation of hyperpress hose technology. Hyperpress hoses are designed to withstand extreme conditions, providing unmatched durability, flexibility, and efficiency in fluid transfer processes across various industries, including construction, manufacturing, agriculture, and automotive sectors. This article explores the significant advantages and applications of hyperpress hoses, showcasing why they have emerged as a vital component in modern fluid delivery systems.

What is Hyperpress Hose?

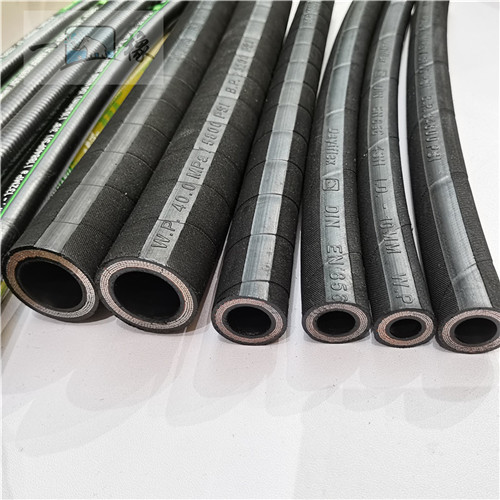

Hyperpress hoses are high-pressure flexible tubes engineered to transport fluids at elevated pressures while maintaining structural integrity. They typically consist of multiple layers of materials such as rubber, polyester, or other synthetic fibers, which work together to enhance the hose's strength and longevity. The inner lining is often crafted to resist abrasion and corrosion, making these hoses suitable for transferring not just water but also chemicals, oils, and other hazardous substances.

Key Advantages of Hyperpress Hose

1. High Pressure Resistance One of the primary benefits of hyperpress hoses is their ability to handle high pressure without compromising performance. This makes them ideal for applications where pressurized fluids are essential, such as in hydraulic systems or for heavy machinery.

2. Enhanced Flexibility Unlike traditional hoses, hyperpress designs incorporate advanced engineering to allow for superior flexibility. This feature makes them easier to maneuver in tight spaces, which is crucial in complex industrial settings.

3. Durability and Longevity The robust construction of hyperpress hoses ensures they can withstand harsh environmental conditions, including extreme temperatures, UV exposure, and exposure to various chemicals. This durability translates to fewer replacements and reduced maintenance costs over time.

hypress hose

4. Safety Features With a strong focus on safety, hyperpress hoses often come equipped with burst protection and other safety mechanisms. This not only protects the hose from failure but also ensures the safety of workers handling potentially hazardous materials.

5. Versatility Hyperpress hoses are versatile and can be employed in a wide array of applications. Whether it’s for transferring water in construction, chemicals in manufacturing, or fuel in automotive industries, these hoses adapt well to different fluids and conditions.

Applications of Hyperpress Hose

The applications of hyperpress hoses are as extensive as their benefits. In the agricultural sector, farmers use them for irrigation purposes, ensuring efficient water delivery under high pressure. In construction, they are essential for powering hydraulic systems that operate equipment like excavators and cranes.

Manufacturers also rely on hyperpress hoses in processes involving high-pressure spraying or chemical transfer, where maintaining the integrity of the fluid is paramount. In the automotive industry, they play a critical role in systems that require reliable and robust fuel lines, brake lines, and cooling systems.

Conclusion

In conclusion, hyperpress hoses represent a significant advancement in fluid transfer technology, offering a combination of strength, flexibility, and safety that traditional hoses cannot match. Their ability to perform under extreme conditions and resist wear makes them an invaluable asset in numerous industrial applications. As industries continue to innovate and seek more efficient ways to operate, the demand for hyperpress hose technology will only increase, solidifying its place as an essential component in the future of fluid delivery systems. Embracing this technology not only enhances operational efficiency but also contributes to a safer working environment across various sectors.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025