335345435

Aug . 06, 2024 13:40 Back to list

Exploring Leading Hydraulic Hose Manufacturers and Factories in China for Quality Solutions

The Rise of Hydraulic Hose Manufacturing in China A Spotlight on Dunlop Factories

In recent years, China has become a global powerhouse in manufacturing, significantly impacting various sectors, including hydraulic hoses. Among the numerous manufacturers within this thriving industry, Dunlop factories stand out due to their innovation, quality, and comprehensive production capabilities. Hydraulic hoses produced by Dunlop in China play a crucial role in various applications, from construction and agriculture to automotive and industrial machinery.

The Importance of Hydraulic Hoses

Hydraulic hoses are essential components in systems that utilize pressurized fluids to transmit power. They are designed to be durable, flexible, and resistant to various environmental factors, ensuring optimal performance under high-pressure conditions. The integrity and reliability of hydraulic hoses directly influence the efficacy and safety of the machines and systems they support. As industries continue to evolve and require advanced hydraulic solutions, the demand for high-quality hoses has surged, placing manufacturers like Dunlop in a prime position to cater to this growing market.

Dunlop's Commitment to Quality and Innovation

Dunlop, a name synonymous with reliability in the manufacturing sector, has established itself as a leading producer of hydraulic hoses in China. The brand is widely recognized for its commitment to quality, employing rigorous testing procedures and adhering to international standards. By utilizing advanced materials and cutting-edge manufacturing techniques, Dunlop ensures that its products are not only compliant with industry norms but also capable of outperforming competitors in durability and longevity.

One of Dunlop's defining characteristics is its focus on research and development. The company invests significantly in innovation to understand better the evolving needs of its customers. By collaborating with engineers and industry experts, Dunlop can introduce new products designed to meet specific demands, including hoses that function well in extreme temperatures or environments with high abrasion. This proactive approach has enabled Dunlop to stay ahead of the competition and maintain a robust market presence.

china dunlop hydraulic hose factories

Sustainable Practices in Manufacturing

As global awareness of environmental issues grows, manufacturers need to adopt sustainable practices to minimize their ecological footprint. Dunlop factories have embraced this challenge by implementing eco-friendly manufacturing processes. From the sourcing of raw materials to waste management and recycling initiatives, Dunlop is committed to reducing its impact on the environment. The adoption of sustainable practices not only benefits the planet but also appeals to environmentally conscious consumers and businesses, enhancing Dunlop's reputation as a responsible manufacturer.

Meeting Global Demand

With China's strategic position in global trade, Dunlop's production capabilities allow it to cater to a vast array of international markets. The factories are equipped with state-of-the-art machinery, enabling mass production without compromising quality. Dunlop's ability to scale its operations efficiently means it can respond swiftly to fluctuations in demand, ensuring that clients receive timely deliveries even during peak periods.

Furthermore, Dunlop’s extensive distribution network facilitates access to its products in various regions, making it a preferred choice for businesses seeking reliable hydraulic solutions. The company's dedication to customer satisfaction is unwavering, with a support system in place to assist clients with product selection, after-sales support, and troubleshooting.

Conclusion

In conclusion, the hydraulic hose manufacturing sector in China, particularly through the efforts of Dunlop factories, has witnessed impressive growth. With a commitment to quality, innovation, and sustainability, Dunlop is well-positioned to meet the challenges of a dynamic market. As industries continue to rely on hydraulic systems, the importance of high-quality hoses will only increase—and Dunlop is ready to lead the way into a more efficient and sustainable future. This journey not only emphasizes the strength of Chinese manufacturing but also highlights Dunlop's pivotal role in this ever-evolving landscape.

-

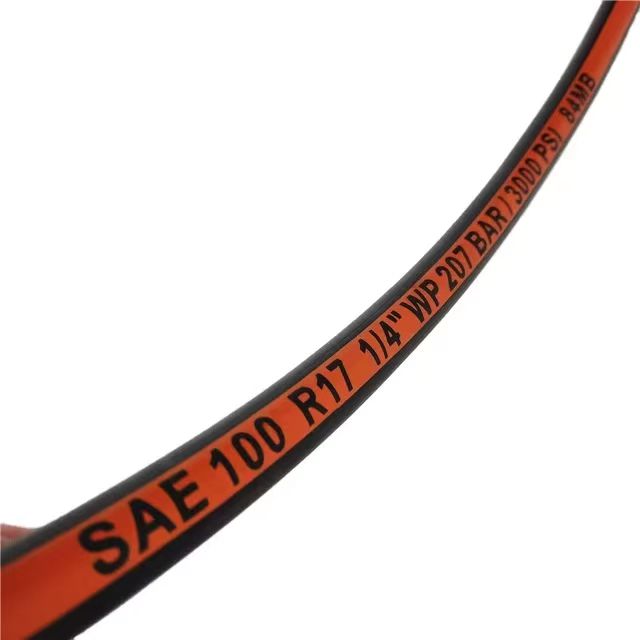

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025