335345435

Aug . 13, 2024 20:13 Back to list

Exploring Current Market Trends and Costs for Hydraulic Hose Products and Their Applications

Understanding Hydraulic Hose Prices Factors and Insights

Hydraulic hoses are essential components in various industrial applications, from construction to agriculture and automotive systems. They serve to transmit fluid power and are crucial for maintaining the efficiency and safety of hydraulic systems. With their importance, understanding the pricing of hydraulic hoses becomes vital for businesses and engineers alike.

Factors Influencing Hydraulic Hose Prices

1. Material Quality The primary determinant of hydraulic hose prices is the material used in production. Hydraulic hoses are often constructed from rubber, thermoplastic, or steel. Rubber hoses are generally more affordable due to their lower production costs. However, hoses designed for high-pressure applications typically require reinforced materials, which can significantly increase the price.

2. Diameter and Length The size of the hydraulic hose also plays a crucial role in pricing. Hoses come in various diameters and lengths to suit specific applications. Typically, larger diameter hoses can handle more fluid, thus increasing their cost. Additionally, longer hoses require more material, which influences the overall price. Custom lengths or unique diameters can lead to further price increases.

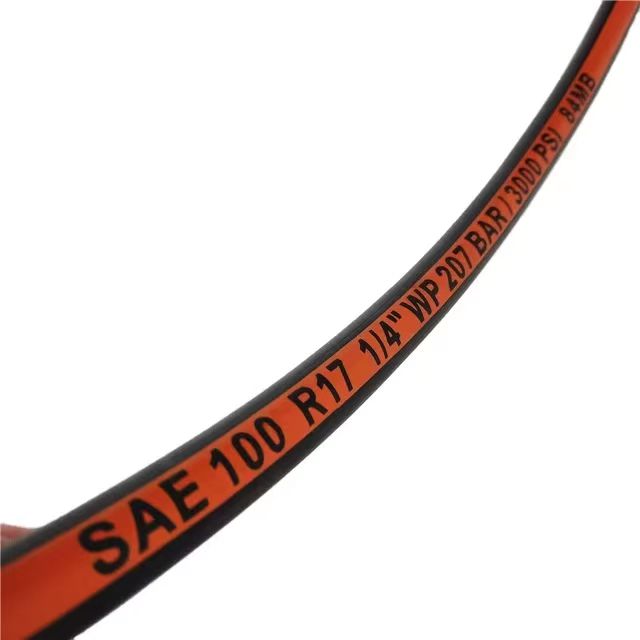

3. Pressure Ratings Hydraulic hoses are categorized based on their pressure ratings, which indicate the maximum pressure they can withstand. High-pressure hoses, designed for demanding applications, are constructed using advanced materials and engineering techniques. Consequently, these hoses command higher prices compared to standard or low-pressure options.

4. Manufacturing Process The method of manufacturing can also affect prices. Some hoses are produced using sophisticated techniques that ensure greater durability and reliability. For instance, hoses that undergo processes like spiral wrapping or multi-layer construction are more expensive, but they also provide enhanced performance and longevity.

hydraulic hose prices

5. Brand and Certification Brand reputation and certification can influence hydraulic hose pricing. Renowned manufacturers that adhere to high-quality standards and certifications, such as ISO or SAE, often charge a premium. Investing in certified hoses can be worthwhile, as they usually offer better performance and safety assurances.

6. Market Demand and Supply Dynamics Like any commodity, the prices of hydraulic hoses are also influenced by market demand and supply. Economic trends, global supply chain issues, and fluctuations in raw material costs can all lead to variations in prices. During periods of high demand or when supply constraints arise, prices may increase significantly.

The Importance of Investing Wisely

When purchasing hydraulic hoses, it is crucial for businesses to consider not only the initial cost but also the long-term value. Cheaper hoses might save money upfront, but if they fail prematurely, they can lead to costly downtime and repairs. Investing in high-quality hoses that meet or exceed industry standards can prove more economical in the long run.

Conclusion

In summary, understanding hydraulic hose prices requires a multifaceted approach that considers various factors, including materials, size, pressure ratings, manufacturing methods, and market dynamics. By being informed about these aspects, businesses can make better purchasing decisions that ensure efficient operations and reduced maintenance costs. Whether for heavy machinery or intricate hydraulic systems, selecting the right hose at the right price is an investment in performance and reliability.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025