335345435

Nov . 30, 2024 02:40 Back to list

en857 1sc suppliers

Understanding EN857 1SC Hydraulic Hoses and Their Suppliers

Hydraulic hoses play a vital role in the operation of machinery and equipment in various industries, including construction, agriculture, and manufacturing. Among the numerous hose specifications available in the market, the EN857 1SC standard stands out as a popular choice for many hydraulic applications. Understanding its features, benefits, and the suppliers who provide these hoses is essential for anyone involved in the use or procurement of hydraulic systems.

What is EN857 1SC?

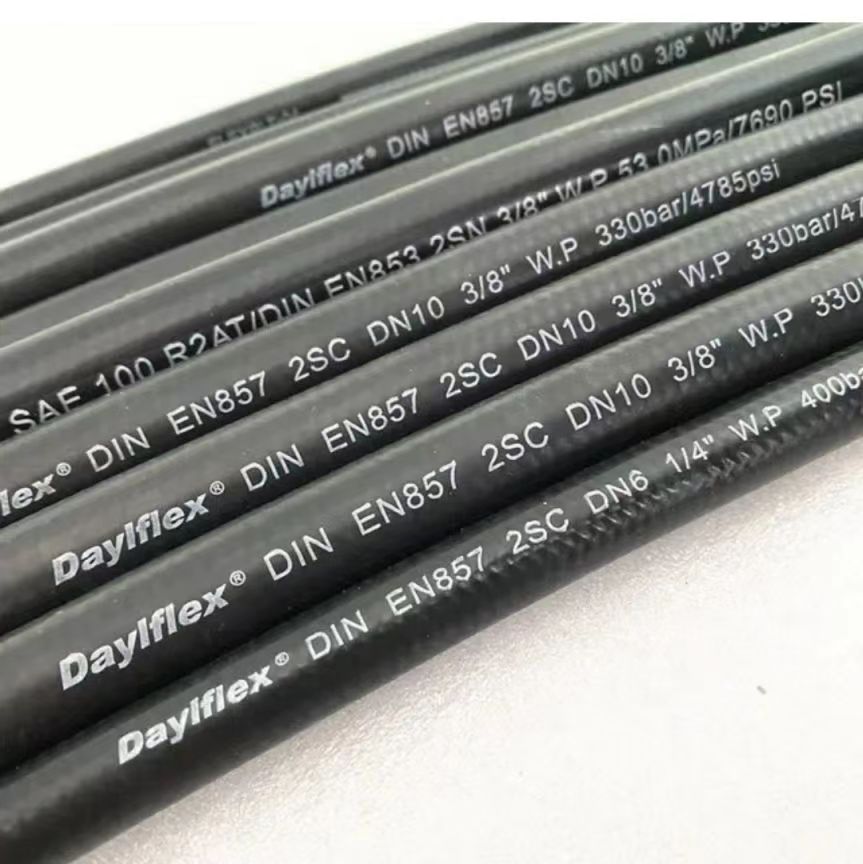

EN857 1SC is a standardized specification for hydraulic hoses that are designed for high-pressure applications. This standard defines the construction, performance characteristics, and testing methods for hoses that are capable of working under high levels of pressure, specifically up to 250 bar (3625 psi) in certain conditions. The 1SC portion of the designation indicates that the hose is a single steel wire braided type, which provides enhanced flexibility and pressure resistance compared to other categories.

The composition of EN857 1SC hoses typically includes a synthetic rubber inner tube that can handle hydraulic fluids, reinforced with one layer of high-tensile steel wire braid. The outer cover is also made of a durable rubber that is resistant to external factors such as abrasion, weather, and oil. This construction offers a balance of flexibility for ease of installation and durability for long-term use.

Benefits of EN857 1SC Hoses

1. High Pressure Resistance One of the key advantages of EN857 1SC hoses is their ability to withstand high working pressures, which is crucial for many industrial applications. 2. Flexibility and Maneuverability These hoses are designed to be flexible, allowing them to be routed and bent easily, facilitating their use in tight spaces and complex machinery setups.

3. Durable Construction With a reliable inner tube and protective outer cover, EN857 1SC hoses are built to resist wear and tear, prolonging their life and reducing the frequency of replacements.

4. Versatility They can be used in various applications ranging from hydraulic differentials to hydraulic pumps, making them a versatile choice for a diverse range of industries.

en857 1sc suppliers

Choosing the Right Supplier

Selecting the right supplier for EN857 1SC hoses is critical for ensuring you receive quality products that can meet your operational needs. Here are some key considerations when choosing a supplier

1. Reputation and Experience Look for suppliers with a solid reputation and experience in the industry. Established suppliers are more likely to adhere to quality standards and provide reliable products.

2. Product Range A good supplier should offer a comprehensive range of hydraulic hoses, including the EN857 1SC specification. This ensures you can source all necessary equipment from a single vendor.

3. Quality Assurance Ensure that the supplier follows rigorous quality control processes in manufacturing. Certifications, such as ISO, can be indicators of a supplier's commitment to quality.

4. Technical Support Choose a supplier that offers technical support to assist with any queries regarding product selection, installation, and maintenance.

5. Customization Options Depending on your project requirements, you may need customized solutions. Suppliers that offer customization demonstrate flexibility and a willingness to meet specific needs.

Conclusion

EN857 1SC hydraulic hoses are essential components in many industrial operations due to their high pressure resistance, flexibility, and durability. Understanding the significance of this specification and carefully selecting a reputable supplier can greatly influence the efficiency and reliability of your hydraulic systems. As industries continue to evolve, staying informed about product specifications and supplier capabilities will ensure the best results for your operations.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025