335345435

Oct . 13, 2024 19:39 Back to list

Supplier Information for EN854 203 TE Specifications and Requirements

Understanding EN854 3TE Supplier A Comprehensive Overview

The EN854 3TE specification is a crucial standard in the world of hydraulic and industrial hoses, ensuring that products meet certain performance metrics and safety standards. This specification is primarily used in Europe and is critical for industries that depend on reliable hose solutions. As manufacturers and suppliers work to provide hoses that conform to this standard, it is essential to understand the significance of EN854 3TE, the importance of quality in supply chains, and the role of verified suppliers in maintaining industry standards.

What is EN854 3TE?

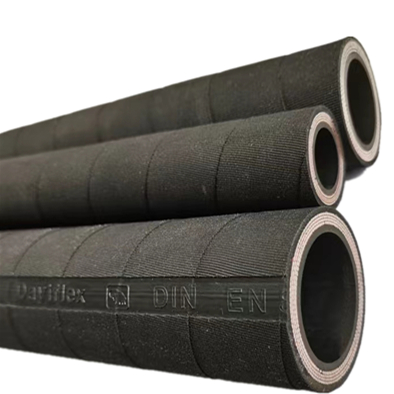

EN854 3TE is a European standard that delineates the requirements for a specific type of synthetic rubber hose. It is categorized under the family of hoses designed for hydraulic applications, featuring a three-layer construction that offers increased durability and flexibility. The 3TE designation indicates the hose's ability to handle specific pressure ratings and temperatures, making it ideal for a range of applications, including mobile machinery, agriculture, and manufacturing.

The hose typically consists of an inner layer designed to withstand high-pressure fluids, a middle layer for reinforcement, and an outer layer that provides protection against environmental factors such as abrasion and oil. Knowing the specifications laid out by EN854 ensures that engineers and procurement professionals select the right hose for their applications, minimizing the risk of failure that could jeopardize safety and productivity.

Importance of Quality Suppliers

As industries increasingly rely on specialized components like hoses, the need for quality suppliers becomes paramount. An EN854 3TE supplier plays a vital role in ensuring that hoses meet the defined standards. Poor-quality hoses can lead to system failures, posing significant risks to machinery and personnel. Therefore, sourcing from verified suppliers with a strong track record of compliance with industry standards is essential.

Quality suppliers not only provide products that meet EN854 standards but also contribute to the overall efficiency of operations. They often have the capabilities to conduct rigorous testing and manufacturing processes, ensuring that every batch of hoses is consistent in quality. Furthermore, reputable suppliers stay updated with industry changes, including innovations in materials and manufacturing techniques, which can lead to improved performance and safety.

en854 3te supplier

Building Long-Term Relationships

Establishing a long-term relationship with an EN854 3TE supplier can lead to numerous benefits for businesses. A trusted supplier often provides tailored solutions that align with specific operational needs, including custom lengths, diameters, or end fittings for hoses. This can enhance the efficiency of different applications and minimize downtime caused by incompatible equipment.

Additionally, long-standing relationships foster better communication, allowing for quicker responses to issues that may arise. Suppliers who understand the operational context of their clients can offer valuable insights or alternative solutions that may not have been previously considered. This collaborative approach can lead to ongoing improvements in performance and cost savings over time.

The Future of EN854 3TE Hoses

Looking ahead, it is essential for manufacturers and suppliers to adapt to the growing demands for enhanced performance, sustainability, and safety in hose applications. Trends toward eco-friendly materials and production processes are shaping the future of industrial hoses, including those meeting EN854 standards. Suppliers that invest in research and development will likely lead the way in providing innovative hose solutions that not only meet regulatory requirements but also align with the sustainability goals of their clients.

Furthermore, the evolution of smart technology in industrial applications is also influencing the design and functionality of hoses. With the advent of Internet of Things (IoT) technologies, there is a potential for hoses to be embedded with sensors that monitor pressure, temperature, and overall system performance. This kind of advancement would revolutionize preventive maintenance, allowing for proactive measures to avoid failures.

Conclusion

In summary, the EN854 3TE specification is a vital standard for hydraulic hoses, emphasizing the importance of quality, reliability, and safety. Engaging with verified suppliers who understand and adhere to these standards is crucial for any business that relies on such components. By building strong partnerships with quality suppliers, businesses can enhance their operational efficiency, reduce risks, and adapt to evolving industry demands. As we progress into a future where innovation and sustainability take precedence, the role of EN854 3TE suppliers will undoubtedly become even more significant. Ultimately, the pursuit of excellence in hose supply chains will contribute to safer and more efficient industrial operations globally.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025