335345435

Nov . 20, 2024 11:45 Back to list

en854 3te factory

EN854 3TE Factory A Leading Manufacturer in the Hydraulic Hose Industry

In the ever-evolving world of industrial machinery and equipment, the importance of reliable hydraulic systems cannot be overstated. A critical component in these systems is the hydraulic hose, and the EN854 3TE specification stands as a benchmark for performance and safety. This article delves into the significance of the EN854 3TE factory, its production processes, and the essential role it plays in the broader hydraulic hose industry.

The EN854 3TE specification is primarily known for its designation of construction and testing standards for hydraulic hoses designed for high-pressure applications. These hoses are primarily constructed from synthetic rubber, reinforced with high-tensile textile or steel wire, providing the necessary resilience and flexibility to withstand extreme conditions. The EN854 3TE model is particularly suited for medium pressure applications, making it an ideal choice for various industrial settings, including construction, agriculture, and manufacturing.

EN854 3TE Factory A Leading Manufacturer in the Hydraulic Hose Industry

One of the key strengths of the EN854 3TE factory is its ability to adapt to the changing demands of the market. The factory invests heavily in research and development to innovate and enhance its product offerings. By staying attuned to industry trends and technological advancements, the factory can introduce new products that meet evolving customer needs. This flexible approach has positioned the EN854 3TE factory as a leader in the hydraulic hose market, capable of providing solutions for both standard and specialized applications.

en854 3te factory

Furthermore, the factory is deeply committed to sustainability. In recent years, there has been an increased focus on environmentally friendly manufacturing processes. The EN854 3TE factory has embraced this trend by implementing sustainable practices, such as reducing waste, recycling materials, and optimizing energy use during production. This commitment to sustainability not only benefits the environment but also resonates with customers who prioritize eco-friendly products.

The logistics and supply chain management at the EN854 3TE factory are also noteworthy. With a comprehensive distribution network, the factory ensures that its products are readily available to customers across various regions. Timely delivery is crucial in industries reliant on hydraulic systems, and the factory's efficiency in logistics helps its clients avoid costly downtimes.

Moreover, the EN854 3TE factory places a high emphasis on customer satisfaction. By offering personalized support and expert advice, the factory helps customers select the right products for their specific needs. This customer-centric approach fosters long-term relationships and has cultivated a loyal client base.

In conclusion, the EN854 3TE factory stands as a significant player in the hydraulic hose industry. With its stringent quality standards, commitment to innovation, sustainable practices, and unwavering focus on customer service, the factory not only meets but often exceeds industry expectations. As the demand for reliable, high-performance hydraulic hoses continues to grow, the EN854 3TE factory is well-equipped to lead the way, setting standards for excellence in manufacturing and contributing to the advancement of hydraulic technologies.

-

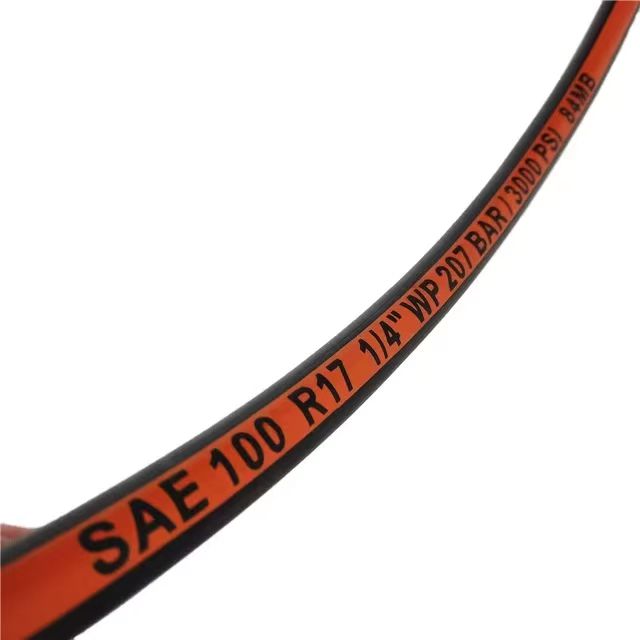

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025