335345435

Jul . 27, 2024 07:15 Back to list

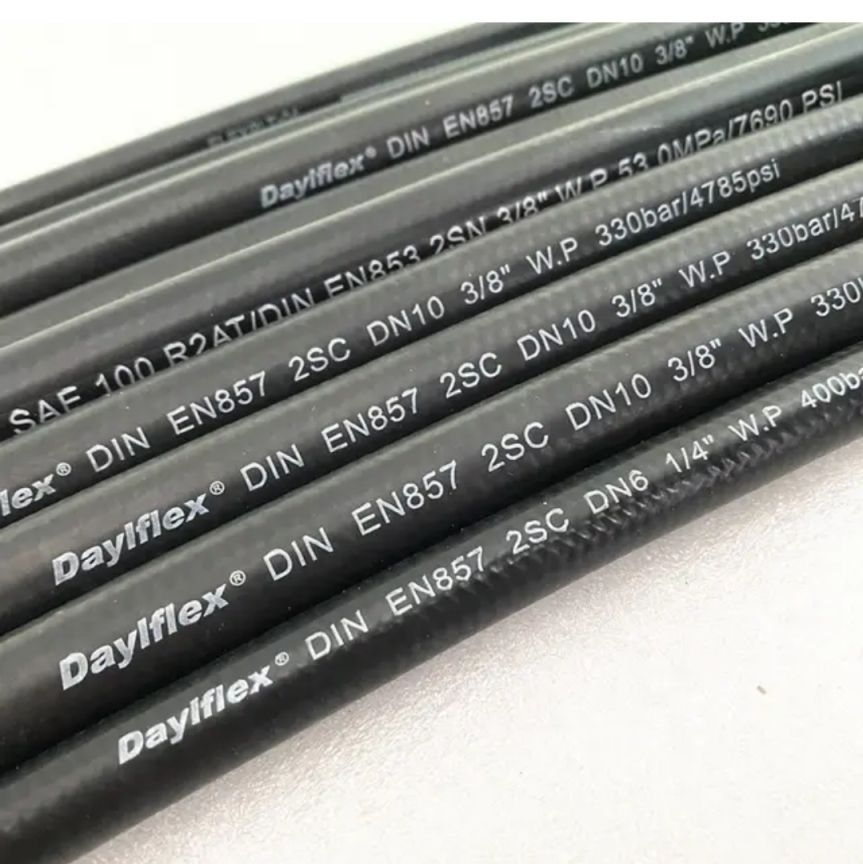

Customizable LPG Hose with OEM Braided Design for Enhanced Durability and Performance.

Understanding OEM Braided LPG Hoses An Essential Component for Safe Gas Handling

In industries that rely on liquefied petroleum gas (LPG), the importance of reliable and durable hoses cannot be overstated. Among the various options available, OEM (Original Equipment Manufacturer) braided LPG hoses have gained significant attention for their superior design and engineering. This article explores the features, benefits, and applications of OEM braided LPG hoses, emphasizing their critical role in ensuring safety and efficiency in gas handling.

What is an OEM Braided LPG Hose?

OEM braided LPG hoses are specifically designed and manufactured to meet the stringent standards set by industry regulators and manufacturers. These hoses typically consist of a rubber tube that is reinforced with braided layers, often made from high-strength materials like stainless steel or synthetic fibers. This braided construction not only provides enhanced strength and durability but also helps in preventing leaks and bursting under high pressure.

Key Features

1. Durability The braided design considerably increases resistance to wear and tear, making these hoses suitable for long-term use. They can withstand harsh weather conditions and are less prone to aging, cracks, or other forms of damage.

2. Flexibility Despite their durability, OEM braided LPG hoses offer excellent flexibility, allowing them to be maneuvered easily in tight spaces. This feature is crucial in various applications where the routing of gas lines must navigate around machinery or other equipment.

3. Safety Safety is paramount when handling LPG, which is highly flammable. The braided construction significantly reduces the risk of ruptures and leaks, helping to prevent potentially dangerous situations. Many OEM hoses come with additional safety features, such as built-in leak detection systems.

4. Compatibility OEM braided LPG hoses are designed to be compatible with various LPG systems, making them a versatile choice for different applications, from residential to industrial uses.

Benefits of Using OEM Braided LPG Hoses

oem braided lpg hose

1. Reliability When it comes to transporting LPG, reliability is crucial. OEM braided hoses provide peace of mind, as they are designed to the exact specifications needed to handle high-pressure situations.

2. Reduced Maintenance With their durable nature, these hoses require less frequent replacement and maintenance, leading to lower operational costs for businesses.

3. Enhanced Performance The high-strength materials used in OEM braided hoses ensure that they can perform well even in demanding conditions. This translates to improved efficiency in gas delivery and usage.

4. Regulatory Compliance OEM hoses are manufactured according to industry standards and regulations, ensuring that users remain compliant with safety and operational guidelines.

Applications of OEM Braided LPG Hoses

OEM braided LPG hoses are used across various sectors, including

- Residential Heating Many homes use LPG for heating purposes. Braided hoses ensure safe and efficient delivery from cylinders to appliances. - Commercial Cooking Restaurants often rely on LPG for cooking. OEM hoses provide safe connections between gas sources and cooking equipment.

- Industrial Applications Many industries utilize LPG for various processes, including manufacturing and heating. The reliability and safety of OEM braided hoses make them ideal for these environments.

Conclusion

The use of OEM braided LPG hoses is critical in ensuring the safe and efficient handling of liquefied petroleum gas across various applications. With their robust construction, flexibility, and adherence to safety standards, these hoses stand out as a reliable solution for anyone involved in the LPG industry. Whether for residential, commercial, or industrial use, investing in high-quality OEM braided LPG hoses is a wise decision that pays off in safety and performance.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025