335345435

Aug . 08, 2024 08:20 Back to list

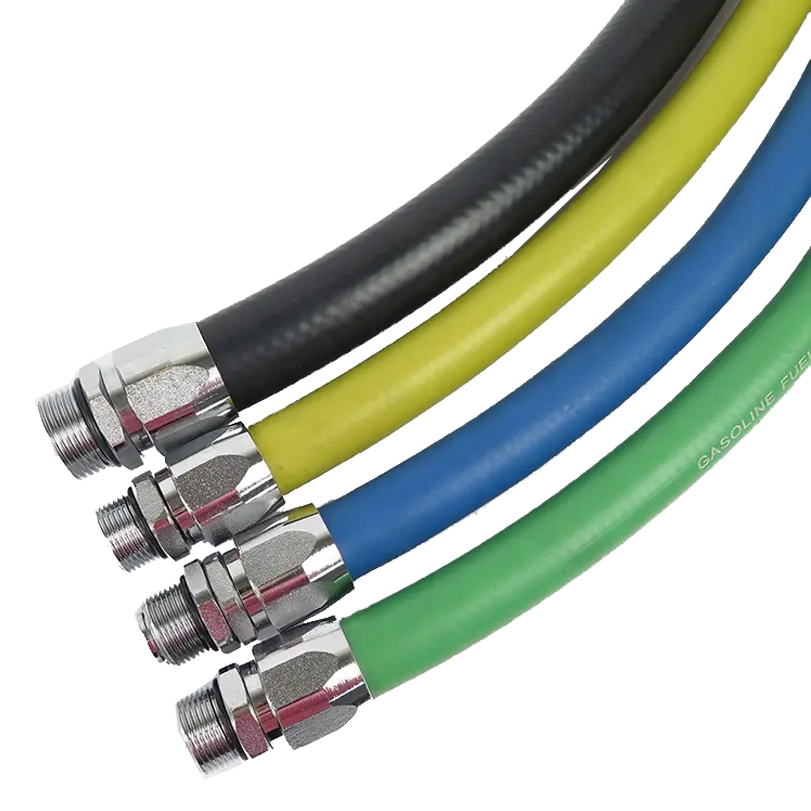

Custom PTFE Flexible Hose Pipe Manufacturers for High-Performance Applications and Quality Solutions

Exploring OEM PTFE Flexible Hose Pipe Factories

In today's industrial landscape, the demand for high-performance materials is paramount. One such material that has gained significant attention is Polytetrafluoroethylene (PTFE), particularly in the context of flexible hose pipes. OEM (Original Equipment Manufacturer) PTFE flexible hose pipes are becoming essential components in various industries, including chemical, pharmaceutical, food processing, and automotive. This article delves into the significance, manufacturing processes, and benefits of PTFE flexible hose pipes produced by OEM factories.

Understanding PTFE and Its Importance

PTFE is a synthetic polymer known for its high resistance to heat, chemicals, and electrical conductivity. This unique combination of properties makes PTFE ideal for applications that require durability and reliability. Flexible hose pipes made from PTFE are extensively used to transport fluids in environments that would otherwise compromise the integrity of standard hoses. The ability to maintain flexibility while resisting harsh conditions is a critical advantage that PTFE offers over traditional rubber or plastic hoses.

The Role of OEM Factories

OEM factories play a crucial role in the production of PTFE flexible hose pipes. These factories specialize in creating customized products tailored to the specific requirements of their clients. By focusing on OEM production, these factories offer several advantages

1. Customization OEM manufacturers can produce PTFE hoses to meet exact specifications, including size, length, and fitting types. This level of customization is essential for industries that require specialized solutions.

2. Quality Assurance Established OEM factories often adhere to rigorous quality control measures. This ensures that every hose pipe produced meets industry standards and regulations, thus assuring reliability and safety for end-users.

3. Cost Efficiency By leveraging economies of scale and streamlined production processes, OEM factories can often offer competitive pricing. This cost-efficiency is crucial for businesses looking to manage their budgets without compromising on quality.

4. Innovation Many OEM manufacturers invest in research and development to improve their products continuously. This commitment to innovation allows them to stay ahead of the curve in terms of material science and manufacturing technologies, enabling them to produce hoses that offer superior performance.

oem ptfe flexible hose pipe factories

Manufacturing Process

The manufacturing process of OEM PTFE flexible hose pipes typically involves several key steps

1. Material Preparation High-quality PTFE resin is sourced and prepared for processing. The purity of the raw material is crucial, as it directly impacts the final product's performance.

2. Extrusion The prepared PTFE is then extruded into various shapes and sizes, forming the hose's core. This step requires precise control over temperature and pressure to ensure uniformity.

3. Reinforcement Depending on the application, the hoses may need reinforcement to enhance their strength and durability. This can involve the addition of materials such as stainless steel or other woven fabrics.

4. Finishing After extrusion and reinforcement, the hoses undergo various finishing processes, including cutting to size, adding fittings, and performing quality inspections.

5. Testing Rigorous testing is conducted to ensure that the hoses can withstand the required pressure and temperature conditions. Only hoses that pass these tests are packaged and shipped to customers.

Conclusion

OEM PTFE flexible hose pipes represent a cornerstone of modern industrial applications, offering unmatched flexibility and resistance to challenging environments. The role of dedicated OEM factories in producing these hoses cannot be overstated, as they not only provide customized solutions but also uphold stringent quality standards. As industries continue to evolve, the significance of PTFE flexible hoses and the factories that manufacture them will only grow, making them an integral part of the future of industrial manufacturing.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025