335345435

Jan . 11, 2024 09:22 Back to list

Correct Use And Type Selection Of Hyd Hose(Hydraulic Hoses)

Hyd hose(Hydraulic hoses) are usually connected to hydraulic pumps, valves, cylinders, and other components according to the needs of the hydraulic system, and are used to transmit hydraulic media, such as hydraulic oil. When installing and using a hydraulic hose pipe, you need to pay attention to the following points: Select the appropriate material and type of hose to ensure that it can withstand the system's working pressure and the nature of the fluid. When installing a hydraulic hose pipe, you need to avoid excessive twisting or stretching, as well as friction and squeezing with other mechanical parts to avoid damage to the hose. Regularly check the appearance of hydraulic hose pipes to detect wear, cracks, deformation, etc., and replace damaged hoses promptly. Use appropriate fittings and connections to connect hoses and other hydraulic components to ensure a reliable, leak-free seal. During the use of hydraulic pressure hose, avoid being affected by external factors such as high temperature, chemical corrosion, and mechanical impact. In short, the correct use and maintenance of hydraulic hoses is crucial to the safe and stable operation of the hydraulic system. Of course, there are many styles of hydraulic pressure hose. Here we briefly introduce the two main styles.

What Are The Types Of Hyd Hoses (Hydraulic Hoses)?

Many types of hydraulic pressure hoses can usually be classified according to different uses and working conditions. Here we mainly introduce the following two types:

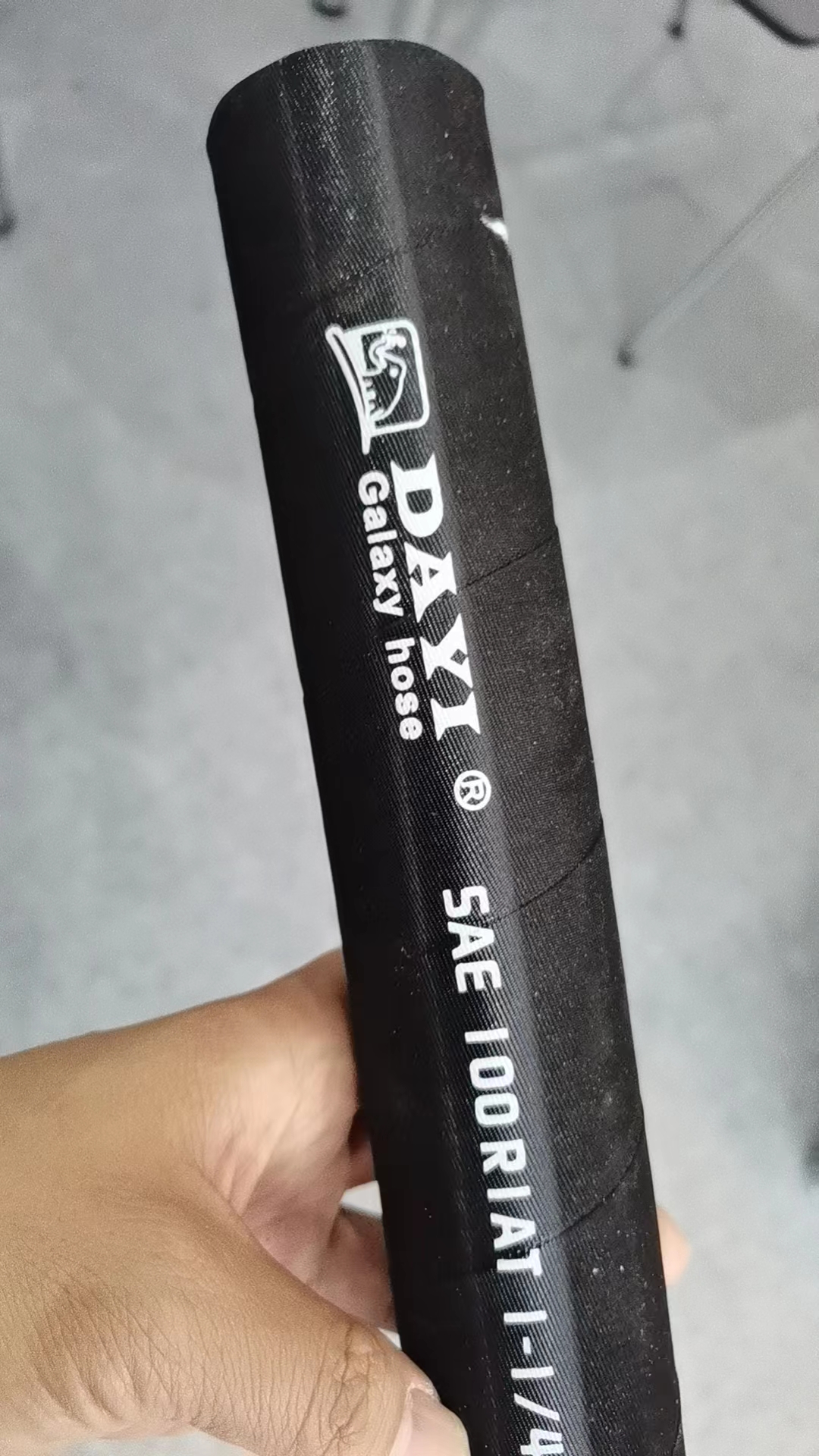

Wire braided hydraulic hose: It is composed of an inner rubber layer, a reinforcement layer, and an outer rubber layer. The reinforcement layer is usually braided with steel wire or spirally wound and is suitable for high-pressure hydraulic systems, such as excavators, presses, etc.

Fiber braided hydraulic hose: It is lightweight and soft. The reinforcement layer is usually braided with high-strength synthetic fibers. It is suitable for medium and low-pressure hydraulic systems, such as engineering machinery, agricultural equipment, etc.

How To Choose Between Fiber Braided Hydraulic Hose And Steel Wire Braided Hydraulic Hose?

Fiber braided hydraulic hose is usually composed of fiber fiber-braided layer and a rubber inner layer. It is suitable for low to medium-pressure hydraulic systems and has good flexibility and lightness. Steel wire braided hydraulic hose uses steel wire braid as reinforcing material, which is suitable for high-pressure hydraulic systems and has strong pressure resistance and wear resistance.

When selecting fiber-braided hydraulic hose or wire-braided hydraulic hose, here are some factors to consider:

Working pressure: Steel wire braided hydraulic hose is suitable for high-pressure hydraulic systems, while fiber braided hydraulic hose is suitable for low to medium-pressure systems.

Usage environment: If used in harsh environments, such as high temperatures, chemical corrosion, etc., steel wire braided hydraulic hoses may be more suitable.

Cost: Wire-braided hydraulic hose is generally more expensive than fiber-braided hydraulic hose and needs to be considered based on budget.

-

LPG Hose for Sale: A Wholesaler’s Guide to Sourcing Safe and Profitable Solutions

NewsJun.23,2025

-

Rubber Pipes for Sale: A Wholesaler’s Blueprint for Sourcing Premium Industrial Solutions

NewsJun.23,2025

-

Hydraulic Hose Wholesale: A Wholesaler’s Playbook for Strategic Sourcing

NewsJun.23,2025

-

Power Washer Hoses for Sale: A Wholesaler’s Guide to Smart Sourcing

NewsJun.23,2025

-

Hydraulic Fittings for Sale: A Wholesaler’s Guide to Mastering Compatibility and Compliance

NewsJun.23,2025

-

Hydraulic Pipe Crimper for Sale: A Wholesaler’s Guide to Sourcing Premium Crimping Solutions

NewsJun.23,2025