335345435

Jul . 25, 2024 09:03 Back to list

Comprehensive Guide to Hydraulic Hoses and Fittings for Optimal Performance and Reliability

Hydraulic Hoses and Fittings Essential Components for Fluid Power Systems

Hydraulic hoses and fittings are integral components of hydraulic systems, utilized across various industries including construction, manufacturing, and automotive. Understanding the characteristics, types, and importance of these components can provide valuable insights into their role in ensuring the efficient operation of fluid power systems.

Understanding Hydraulic Hoses

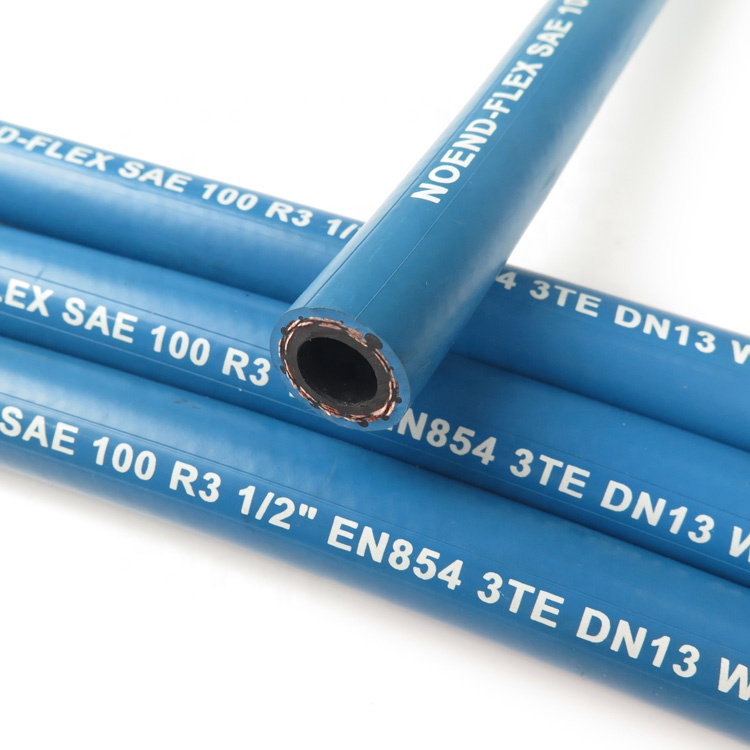

Hydraulic hoses are flexible tubes designed to transport hydraulic fluid between different parts of a hydraulic system. These hoses are constructed to handle high-pressure environments and often consist of an inner tube, reinforcement layers, and an outer cover. The inner tube, typically made from synthetic rubber, must resist high pressure and abrasion from the fluid being transported. The reinforcement layers, which may include braided or spiral wire, provide structural integrity and prevent hose rupture under pressure. The outer cover offers protection against environmental factors such as UV radiation, chemicals, and temperature variations.

Various types of hydraulic hoses exist, each tailored for specific applications. Common classifications include standard hydraulic hoses, high-pressure hoses, and specialty hoses designed for unique fluids or conditions. When selecting a hydraulic hose, crucial factors include the hose’s pressure rating, temperature tolerance, and compatibility with the hydraulic fluid used in the system.

Importance of Hydraulic Fittings

Hydraulic fittings are essential for secure connections within hydraulic systems. These fittings ensure that hoses are connected correctly to machinery, pumps, valves, and other components, preventing leaks and maintaining system efficiency. A fitting is crucial for the seamless transfer of hydraulic fluid and comes in various shapes and sizes to accommodate different hose dimensions and connection types.

hydraulic hoses and fittings pdf

There are several common types of hydraulic fittings, including threaded, quick-disconnect, and flanged fittings. Threaded fittings, such as NPT (National Pipe Thread) or BSP (British Standard Pipe), utilize a twisting mechanism to create a leak-proof seal. Quick-disconnect fittings are designed for easy attachment and detachment, facilitating maintenance and system changes without the need for tools. Flanged fittings are commonly used in high-pressure systems, providing a robust connection that can handle significant stress.

The Role of Hoses and Fittings in System Safety and Efficiency

The relationship between hydraulic hoses and fittings is critical for the operational reliability and safety of hydraulic systems. Proper installation and maintenance are paramount; any failure in these components can lead to a hydraulic leak, resulting in product loss, equipment damage, or even workplace accidents. Regular inspection is essential to identify wear and tear, kinks, or any signs of degradation. End-users must adhere to the manufacturer’s guidelines regarding the operating pressure and temperature limits of both hoses and fittings to ensure maximum longevity and performance.

Additionally, the use of high-quality hoses and fittings affects not only safety but also the overall efficiency of hydraulic systems. Leaks or improper connections can lead to reduced pressure and fluid loss, compromising machine performance. Well-maintained hydraulic hoses and fittings contribute to lower operational costs and prolong the lifespan of equipment, ultimately benefiting the bottom line.

Conclusion

In conclusion, understanding hydraulic hoses and fittings is vital for anyone involved in the design, maintenance, or operation of hydraulic systems. These components work in tandem to facilitate the safe transfer of hydraulic fluid under pressure, playing a pivotal role in the efficiency and reliability of fluid power applications. By prioritizing quality and regular maintenance, industries can ensure their hydraulic systems function optimally, enhancing productivity and safety in their operations.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025