335345435

Nov . 09, 2024 04:31 Back to list

Top Manufacturers of CNG Hoses for Reliable Fuel Supply Solutions

The Role of CNG Hose Manufacturers in the Green Energy Revolution

As the world grapples with the pressing challenges of climate change and the need for sustainable energy sources, the focus on cleaner alternatives like Compressed Natural Gas (CNG) has gained significant momentum. Central to the effective utilization of CNG is the importance of high-quality CNG hoses manufactured by specialized companies. This article delves into the critical role of CNG hose manufacturers in advancing green energy solutions and ensuring safety and efficiency in the transportation of natural gas.

Understanding CNG and Its Advantages

Compressed Natural Gas is predominantly used as a cleaner alternative to diesel and gasoline in various applications, including transportation. It emits significantly lower levels of harmful pollutants, such as nitrogen oxides and particulate matter. As cities strive to reduce air pollution and improve public health, CNG has emerged as a practical choice for fleets of vehicles, public transportation systems, and even residential heating purposes.

However, to fully leverage the benefits of CNG, robust infrastructure is essential. This is where CNG hose manufacturers enter the equation, providing the necessary components that facilitate the safe and efficient transfer of natural gas.

The Importance of Quality in CNG Hoses

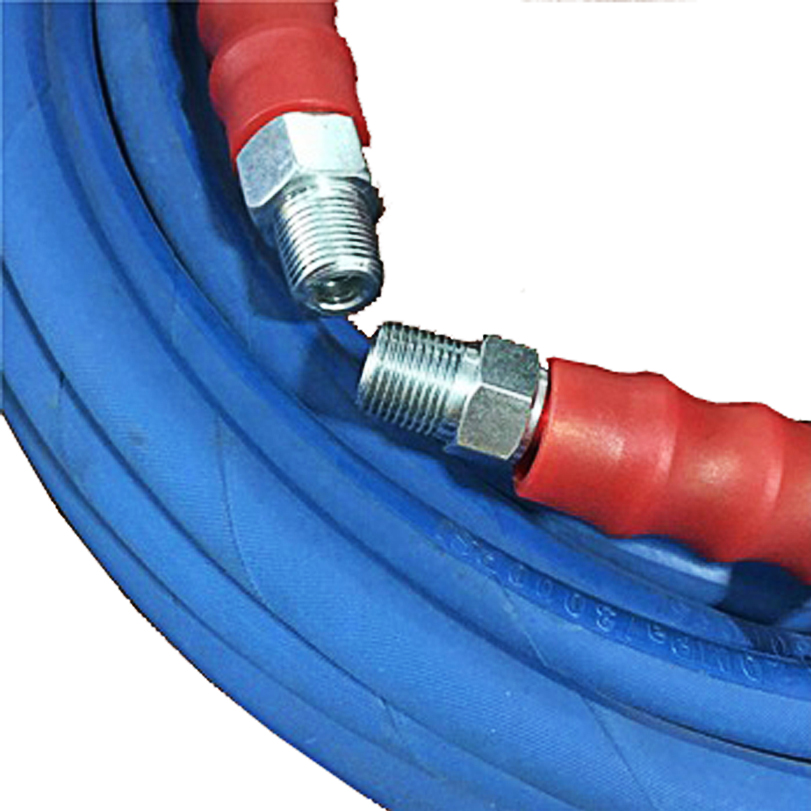

Quality is paramount when it comes to CNG hoses. These hoses operate under high pressure and must withstand not only the mechanical stresses but also the corrosive properties of natural gas. Therefore, the selection of materials and manufacturing processes is crucial. High-quality CNG hoses are designed to be flexible for easy installation while maintaining the integrity needed to ensure safety in gas transfer systems.

CNG hose manufacturers utilize materials such as synthetic rubber reinforced with high-strength fabrics and steel to create hoses that can endure extreme conditions. The testing and certification of these hoses, according to industry standards, authenticate their reliability. Manufacturers often undergo rigorous quality control processes to ensure their products can handle the pressures and demands of various applications while minimizing the risk of leaks or failures.

Innovations in CNG Hose Manufacturing

As technology evolves, so too does the manufacturing of CNG hoses. Manufacturers are constantly innovating, developing new materials and designs that enhance the performance and longevity of hoses. For instance, advancements in polymer technologies have led to the creation of more durable and flexible hose options, which can significantly reduce the chances of wear and tear compared to traditional materials.

cng hose manufacturers

Moreover, manufacturers are increasingly adopting environmentally friendly production processes. By minimizing waste and energy consumption during the manufacturing phase, CNG hose producers contribute to the overall goal of sustainability in the energy sector. Additionally, some manufacturers are exploring biodegradable materials, creating hoses that have a lesser impact on the environment post-consumer use.

Meeting Regulatory Standards

CNG hose manufacturers are also tasked with adhering to strict regulatory standards set forth by various governing bodies. Compliance with safety standards is not just a matter of guidelines but a necessity to ensure public safety. These standards often dictate testing procedures, material specifications, and performance benchmarks to which manufacturers must conform.

Being certified can give manufacturers a competitive edge in the market. It reassures customers of the quality and reliability of their products, which is especially crucial in industries where public safety is a primary concern.

Challenges in the Industry

Despite the growth opportunities in the CNG sector, manufacturers face several challenges. Fluctuating raw material prices, evolving regulations, and the need for continuous innovation can strain operations. Additionally, increasing competition from global players can pressure local manufacturers to enhance efficiency without compromising quality.

To overcome these challenges, many manufacturers are investing in research and development, collaborating with research institutions, and seeking partnerships that can help them stay ahead of technological advancements. Such strategies not only bolster their product offerings but also ensure sustainability in their operations.

Conclusion

CNG hose manufacturers play an indispensable role in the green energy revolution. By providing safe, high-quality, and innovative solutions for transporting natural gas, they contribute significantly to the transition toward cleaner energy sources. As the demand for CNG rises and more applications emerge, the importance of these manufacturers will only continue to grow, establishing them as key players in the quest for a more sustainable future. Their commitment to quality, safety, and innovation is what will propel the industry forward, ensuring that the benefits of CNG are accessible and reliable for generations to come.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025