335345435

Oct . 18, 2024 17:14 Back to list

Two Fiber Braid Hydraulic Hose Manufacturers in China for High-Quality Solutions

The Landscape of China's Two Fiber Braid Hydraulic Hose Manufacturers

Hydraulic hoses are integral components within hydraulic systems, delivering fluids under pressure to various machinery and equipment. Among the different types of hydraulic hoses, those reinforced with two fiber braids are widely recognized for their durability, flexibility, and resistance to environmental factors. China, being one of the largest manufacturing hubs in the world, hosts numerous manufacturers specializing in two fiber braid hydraulic hoses.

The construction of a two fiber braid hydraulic hose typically features an inner rubber layer, which holds the hydraulic fluid, an outer rubber layer for protection, and two layers of braided fibers in between, providing exceptional strength. The braiding process significantly enhances the hose’s pressure ratings, making it suitable for demanding applications in industries like construction, agriculture, and automotive.

Industry Overview

China's hydraulic hose manufacturing sector has witnessed substantial growth over the past few decades. Enabled by modern manufacturing technologies and a skilled workforce, Chinese manufacturers can produce high-quality hoses at competitive prices. This has helped establish China as a key player in the global hydraulic hose market, catering to both domestic and international buyers.

One notable aspect of the Chinese market is the diversity of manufacturers ranging from small-scale workshops to large industrial enterprises. Many companies are equipped with advanced production facilities, utilizing automated processes that enhance both efficiency and quality control. These manufacturers also prioritize research and development, allowing them to innovate and improve their product offerings continuously.

Quality and Standards

china two fiber braid hydraulic hose manufacturers

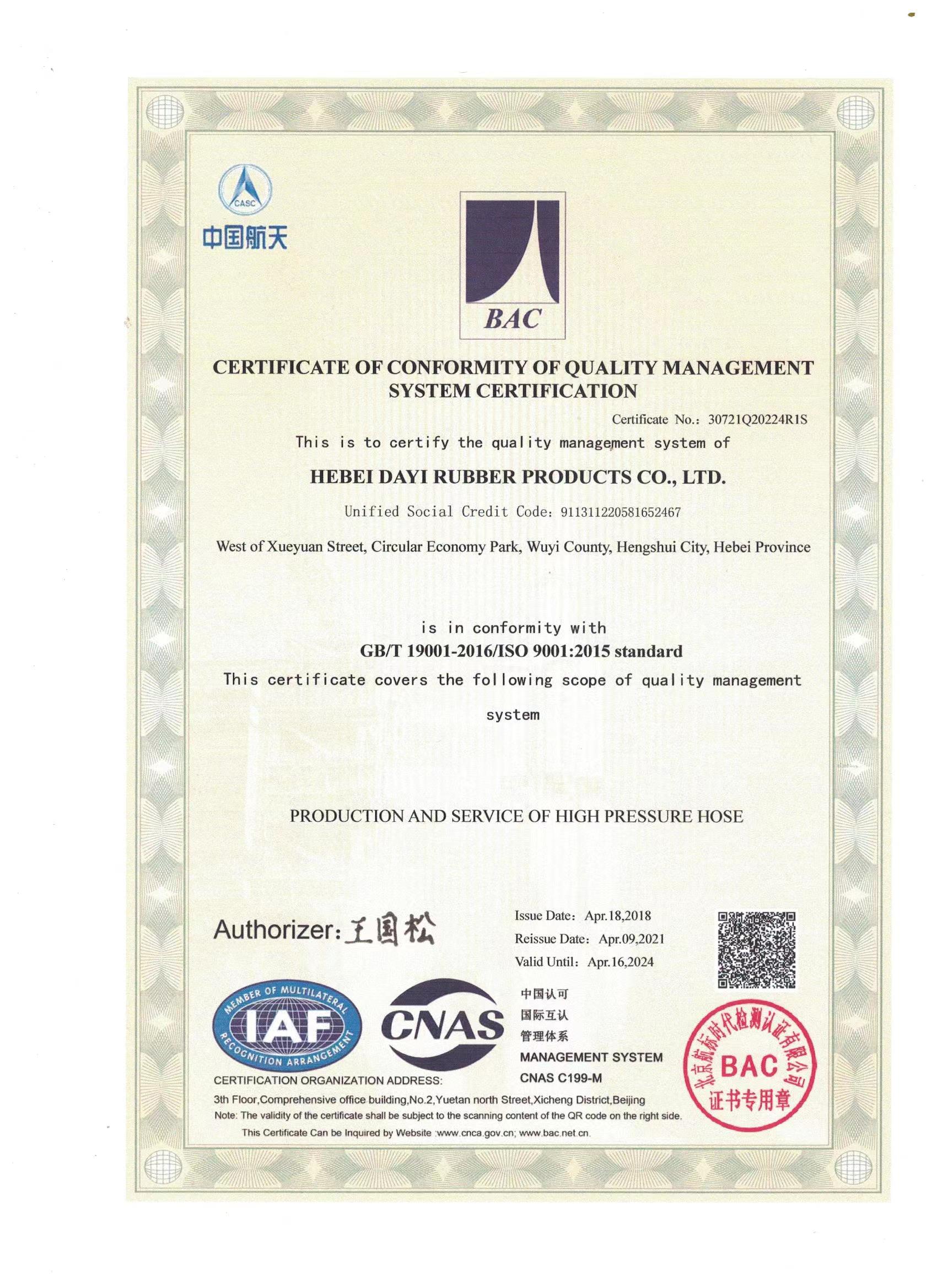

Meeting international quality standards is crucial for manufacturers aiming to succeed in the competitive world of hydraulic hoses. Many Chinese manufacturers have obtained certifications such as ISO 9001 and API, ensuring that their products meet rigorous safety and performance criteria. The use of high-quality raw materials, combined with strict quality assurance processes, contributes to the reliability and longevity of the hoses produced.

Furthermore, some manufacturers focus on customizing solutions tailored to specific client needs. They offer a range of sizes, pressure ratings, and materials, ensuring that clients can find products that precisely meet their operational requirements.

Challenges and Opportunities

While the demand for hydraulic hoses continues to grow, manufacturers in China face challenges such as fluctuating raw material prices and increased competition, both domestically and from international players. To navigate these challenges, many companies are investing in technology to improve their production processes and reduce costs. Additionally, there is a significant push towards sustainability, with manufacturers exploring eco-friendly materials and practices.

China's Belt and Road Initiative also presents new opportunities for hydraulic hose manufacturers. As infrastructure projects ramp up across Asia, Africa, and Europe, the need for reliable hydraulic solutions is set to rise, providing a lucrative market for Chinese producers.

Conclusion

The landscape of two fiber braid hydraulic hose manufacturers in China is evolving, marked by innovation, competitive pricing, and adherence to quality standards. With continuous investments in technology and a growing focus on sustainability, these manufacturers are well-poised to meet the rising global demand for hydraulic hoses. As the industry progresses, Chinese manufacturers will likely play a pivotal role on the international stage, reinforcing their position as leaders in hydraulic hose production.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025