335345435

Nov . 03, 2024 14:41 Back to list

china thermoplastic hydraulic hose manufacturers

The Landscape of Thermoplastic Hydraulic Hose Manufacturers in China

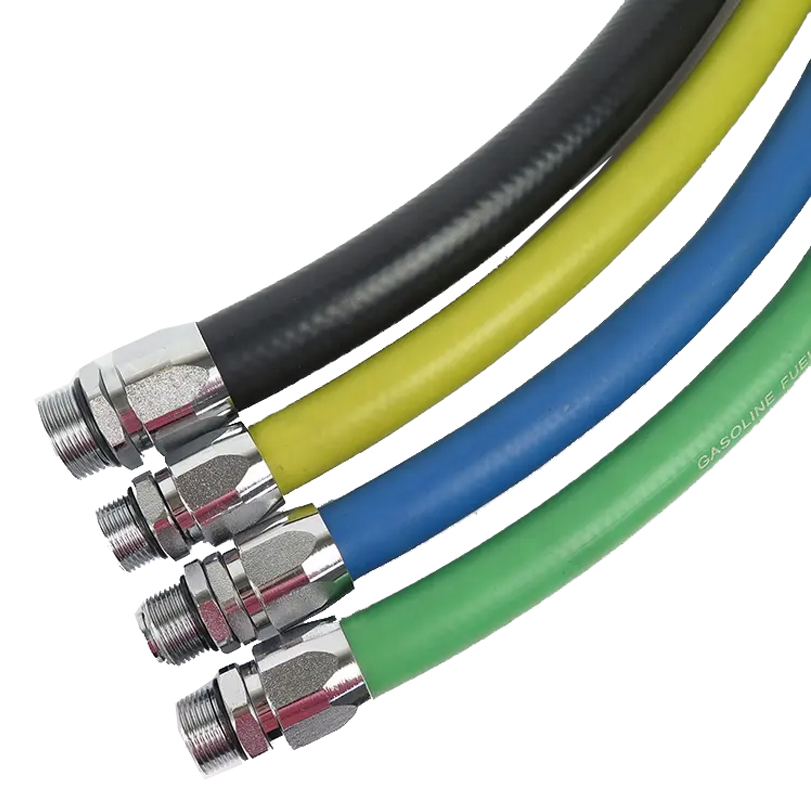

China has rapidly established itself as a global leader in the manufacturing of thermoplastic hydraulic hoses. This surge in production is driven by an increasing demand for high-performance hoses in various industries including construction, agriculture, and automotive. The unique properties of thermoplastic materials make these hoses ideal for a wide range of applications, which in turn enhances their appeal to manufacturers and consumers alike.

Advantages of Thermoplastic Hydraulic Hoses

One of the key benefits of thermoplastic hydraulic hoses is their lightweight nature. Compared to traditional rubber hoses, thermoplastic alternatives are significantly lighter, which makes them easier to handle and install. This characteristic is particularly advantageous in industries where mobility and flexibility are crucial. Additionally, thermoplastic hoses exhibit superior resistance to abrasion, chemicals, and UV radiation, making them suitable for both indoor and outdoor applications.

Thermoplastic hoses also demonstrate excellent pressure resistance and flexibility at high temperatures, further enhancing their versatility. They can be designed to meet specific industry standards, which caters to the needs of various sectors. Considering these benefits, it’s clear why demand for thermoplastic hydraulic hoses is on the rise, positioning China as a pivotal player in the global market.

The Manufacturing Landscape

China hosts a vast number of manufacturers that specialize in the production of thermoplastic hydraulic hoses

. These companies vary significantly in size, ranging from small enterprises to large multinational corporations. Many manufacturers are located in industrial hubs such as Zhejiang, Jiangsu, and Guangdong provinces, which are known for their robust manufacturing infrastructures and supply chain efficiencies.china thermoplastic hydraulic hose manufacturers

These manufacturers invest heavily in research and development to innovate and improve their product offerings. By leveraging advanced technologies and materials, Chinese manufacturers are able to enhance the durability and performance of their hoses, thereby attracting international clients. Moreover, the competitive pricing of these products often gives Chinese manufacturers an edge over their counterparts in other regions.

Quality Standards and Certifications

As the demand for thermoplastic hydraulic hoses grows, so does the need for quality assurance. To maintain a competitive advantage, many Chinese manufacturers have obtained international certifications such as ISO 9001, which signifies adherence to high-quality management standards. Additionally, some manufacturers also comply with specific industry standards like SAE and EN, ensuring that their products meet rigorous performance and safety requirements.

This commitment to quality has allowed Chinese thermoplastic hydraulic hose manufacturers to penetrate various global markets, including Europe, North America, and Asia-Pacific. Furthermore, well-established brands have gained a reputation for reliability and performance, solidifying their position in the global market.

Future Trends

Looking ahead, the future of thermoplastic hydraulic hose manufacturing in China appears promising. With the global shift towards greener technologies and practices, manufacturers are exploring eco-friendly materials and production processes. The integration of smart technologies into manufacturing, such as automation and AI, is also expected to play a significant role, driving efficiencies and improving product quality.

In conclusion, the thermoplastic hydraulic hose manufacturing sector in China is set to thrive, driven by innovation, quality, and a commitment to meeting the evolving demands of the marketplace. As this industry continues to expand, it will undoubtedly play a significant role in the global economy, paving the way for sustainable growth and technological advancement.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025