335345435

Nov . 23, 2024 23:55 Back to list

china sae100r8

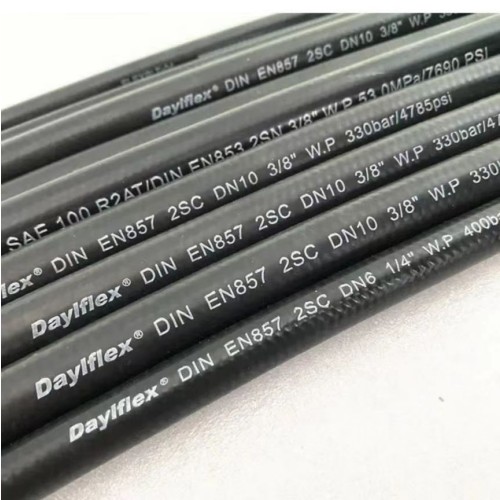

Understanding SAE 100R8 The Hydraulic Hose Standard

When it comes to hydraulic systems, the choice of hoses is critical for ensuring safe and effective operation. One widely recognized standard in the industry is SAE 100R8, which pertains to thermoplastic hydraulic hoses. This standard is crucial for various applications, including construction, agricultural, and industrial machinery, where hydraulic systems play a vital role.

What is SAE 100R8?

SAE 100R8 hoses are specifically designed for conveying hydraulic fluids under high pressure. This particular standard encompasses a range of hoses that are made from thermoplastic materials, which differ significantly from traditional rubber hoses. The construction typically involves a thermoplastic inner tube, reinforced with one or more layers of high-strength textile or wire, and an outer cover of thermoplastic compounds that offer resistance to abrasion and environmental factors.

One of the key advantages of SAE 100R8 hoses is their flexibility. Unlike rubber hoses, which can be bulkier and less maneuverable, SAE 100R8 hoses can withstand tighter bending radii without compromising performance. This flexibility allows for easier installation in complex machinery layouts and can significantly reduce wear and tear during operation.

Applications of SAE 100R8

SAE 100R8 hoses are suitable for various applications that require the transfer of hydraulic fluids, including water-based fluids, petroleum-based fluids, and even biodegradable fluids. Their robustness makes them ideal for high-pressure operations, often rated for pressures exceeding 3000 psi, depending on the specific configuration and diameter of the hose.

china sae100r8

The versatility of SAE 100R8 hoses means they are commonly used in sectors such as

- Agriculture For agricultural machinery like tractors and harvesters. - Construction In excavators, backhoes, and other heavy equipment. - Industrial In manufacturing and assembly facilities where hydraulic power is utilized.

Maintenance and Considerations

Proper maintenance of SAE 100R8 hoses is crucial to ensure their longevity and effectiveness. Regular inspections should be performed to check for signs of wear, such as abrasions, cuts, or leaks. It’s also important to ensure that the hoses are not subjected to conditions beyond their specified pressure and temperature ratings, as this can lead to premature failure.

When replacing hydraulic hoses, it is essential to select the appropriate standard. Using hoses that do not comply with SAE 100R8 can compromise the integrity of the hydraulic system and pose safety risks.

Conclusion

The SAE 100R8 standard represents a significant advancement in hose technology, providing flexibility, durability, and efficiency for hydraulic systems. Whether in agriculture, construction, or industrial applications, understanding and implementing the correct hydraulic hoses is paramount. As industries continue to evolve, staying informed about standards like SAE 100R8 will enable operators to make safe and effective choices that enhance productivity and machine reliability.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025