335345435

Sep . 30, 2024 03:38 Back to list

Exploring Manufacturers of SAE 100R3 Hydraulic Hoses in China

Understanding the SAE 100R3 Standard and Its Factories in China

In the realm of hydraulic hoses, the SAE (Society of Automotive Engineers) standards play a pivotal role in ensuring safety, reliability, and performance in various applications. One of the critical standards in this domain is SAE 100R3, which specifies the requirements for hydraulic hoses that are designed for moderate pressure and low temperature applications. This article delves into the significance of the SAE 100R3 standard and examines the landscape of factories in China producing these essential components.

What is SAE 100R3?

The SAE 100R3 standard refers specifically to hydraulic hoses that are constructed from synthetic rubber and reinforced with textile. This type of hose is known for its flexibility, durability, and resistance to various fluids, making it ideal for use in agricultural machinery, construction equipment, and any application where hydraulic fluid transfer is necessary.

Hoses conforming to SAE 100R3 must meet certain criteria regarding pressure, temperature, and performance. Typically, these hoses are rated for pressures up to 300 psi and can operate in temperatures ranging from -40°F to +212°F. The flexibility of these hoses allows for ease of installation in various configurations while maintaining the required performance standards.

The Role of Chinese Factories

China has emerged as a significant player in the global manufacturing landscape, particularly in producing hydraulic hoses, including those conforming to the SAE 100R3 standard. The growth of the hydraulic hose manufacturing sector in China is driven by several factors

1. Cost-Effectiveness Chinese manufacturers benefit from lower labor costs and economies of scale, allowing them to produce high-quality products at competitive prices. This affordability makes Chinese-made SAE 100R3 hoses attractive to both domestic and international markets.

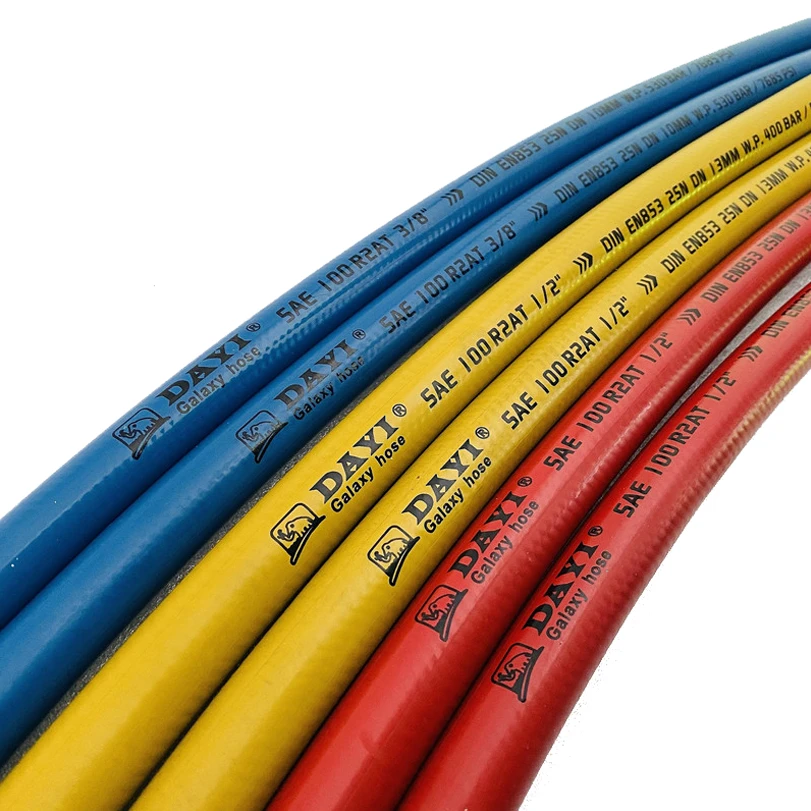

china sae100r3 factories

2. Advanced Manufacturing Techniques Many factories in China have adopted modern manufacturing technologies, enabling them to improve efficiency and product quality. Techniques such as automated production lines and stringent quality control measures ensure that the hoses meet or exceed international standards.

3. Diverse Product Offerings Chinese factories often produce a wide range of hydraulic hoses beyond SAE 100R3, offering various specifications and sizes tailored to different applications. This versatility provides customers with comprehensive sourcing options for their hydraulic system needs.

4. Export Capabilities With robust logistics networks and trade agreements, Chinese manufacturers can efficiently export their products worldwide. This global reach has allowed them to establish strong relationships with distributors and end-users across different industries.

Quality Standards and Certifications

While the cost benefits are appealing, quality must never be compromised when sourcing hydraulic hoses. Reputable Chinese factories producing SAE 100R3 hoses often obtain necessary certifications, such as ISO 9001, which establishes a framework for consistent quality management. Additionally, many of these manufacturers adhere to industry-specific standards, ensuring that their products undergo rigorous testing and certification processes.

Conclusion

The SAE 100R3 standard plays an essential role in the hydraulic hose market, and the factories in China are at the forefront of its production. With their ability to offer cost-effective solutions, advanced manufacturing capabilities, and a commitment to quality, Chinese manufacturers have established themselves as reliable sources for hydraulic hoses globally. As industries continue to evolve and expand, the significance of maintaining high standards for hydraulic components becomes even more critical. Thus, businesses looking to source SAE 100R3 hoses must carefully evaluate their suppliers in China, considering both price and quality to ensure long-term reliability and safety in their operations.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025