335345435

Dec . 01, 2024 08:40 Back to list

China SAE 100R14 Manufacturer for High-Quality Hydraulic Hoses and Components

The Importance of SAE 100R14 Standards in Hydraulic Hose Manufacturing

In the world of hydraulic systems, the performance and reliability of hoses play a vital role in ensuring that machinery operates efficiently. Among the various standards established for hydraulic hoses, the SAE 100R14 is highly regarded for its structural integrity and performance characteristics. This article delves into the significance of the SAE 100R14 standard, particularly focusing on factories in China that manufacture these essential components.

The SAE 100R14 standard specifically pertains to PTFE (polytetrafluoroethylene) hoses used in hydraulic applications. PTFE hoses are known for their excellent chemical resistance, high-temperature tolerance, and low friction characteristics, making them ideal for transferring various fluids, including corrosive substances. The standard outlines specific performance criteria that manufacturers must adhere to, ensuring that the hoses meet rigorous safety and performance guidelines.

The Importance of SAE 100R14 Standards in Hydraulic Hose Manufacturing

One of the primary advantages of sourcing SAE 100R14 hoses from Chinese manufacturers is the cost efficiency. With lower production costs and access to a vast supply chain infrastructure, these factories can offer competitive pricing without compromising quality. Moreover, the high volume of production capabilities allows for a quicker turnaround time on orders, which is crucial in industries where downtime can be costly.

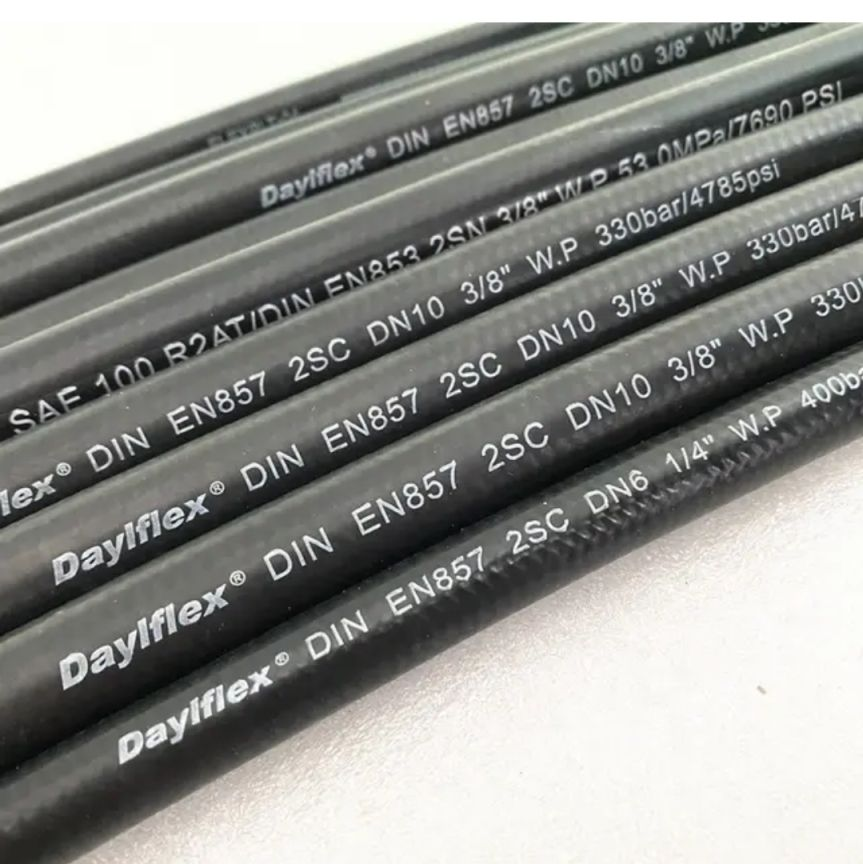

china sae100r14 factory

Chinese manufacturers typically follow strict quality control measures to ensure that their hoses meet SAE 100R14 specifications. This includes rigorous testing for pressure performance, flexibility, and resistance to high temperatures and chemicals. By adhering to these standards, these factories can guarantee that their products will perform reliably in various applications, ranging from manufacturing to transportation and aerospace.

Another aspect to consider is the certifications and recognition that reputable Chinese factories achieve. Compliance with international standards not only boosts credibility but also assures clients of the quality and safety of the products. Many of these manufacturers hold ISO certifications and have established partnerships with well-known international brands, further solidifying their standing in the global market.

Moreover, as environmental concerns continue to gain prominence, Chinese manufacturers are increasingly adopting sustainable practices. Investment in eco-friendly materials and waste reduction initiatives is becoming common, reflecting a growing awareness of environmental responsibility in the industry. This shift not only benefits the planet but also helps manufacturers meet the expectations of socially conscious consumers and businesses.

In conclusion, the SAE 100R14 standard represents a critical benchmark in the hydraulic hose industry, and Chinese factories play a significant role in its production. With advanced technology, a commitment to quality, and competitiveness on pricing, these manufacturers are well-positioned to meet the growing global demand for reliable hydraulic hoses. As industries continue to evolve, the importance of adhering to such standards will only increase, making it essential for manufacturers to maintain high levels of excellence in their production processes. By doing so, they not only contribute to the efficiency and safety of hydraulic systems worldwide but also solidify their reputation in the global market.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025