335345435

Aug . 10, 2024 22:15 Back to list

China's Leading Manufacturers of High-Pressure Steel Wire Braided Hydraulic Hoses for Various Applications

The Rise of China’s High-Pressure Steel Wire Braided Hydraulic Hose Factories

In the global manufacturing landscape, China has grown to become a prominent player in various industrial sectors, with hydraulic hoses being a vital component in numerous applications ranging from machinery to automotive industries. Among the array of hydraulic hoses, high-pressure steel wire braided hydraulic hoses have gained particular importance due to their durability and reliability under extreme conditions. This article will explore the growth, advantages, and challenges faced by China’s high-pressure steel wire braided hydraulic hose factories.

Overview of Hydraulic Hoses

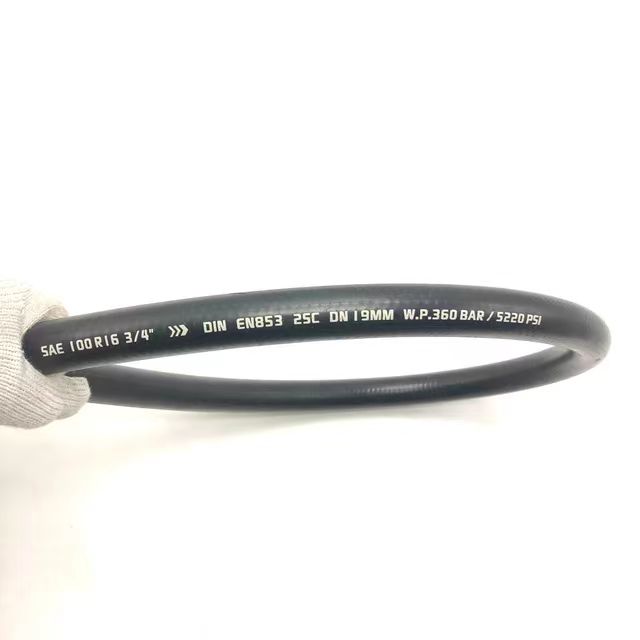

Hydraulic hoses are essential components in hydraulic systems, primarily used to transport hydraulic fluids efficiently. These hoses must withstand high pressure and temperature variations, making the choice of materials and manufacturing techniques critical. Among the various types available in the market, high-pressure steel wire braided hydraulic hoses are distinguished by their construction, which includes multiple layers of synthetic rubber and steel wire braids. This construction provides excellent tensile strength and resistance to abrasion, leading to enhanced performance and longevity.

The Growth of Chinese Factories

The emergence of high-pressure steel wire braided hydraulic hose factories in China can be attributed to several factors. First is the country's economic growth, which has propelled investment in manufacturing capabilities. As industries such as construction, agriculture, mining, and transportation continue to expand, the demand for hydraulic hoses has surged. Chinese factories have responded effectively by ramping up production capacity and investing in advanced technology to meet both domestic and international market needs.

Furthermore, China benefits from a vast network of suppliers for raw materials, reducing production costs and enabling competitive pricing. The country has also developed a skilled workforce proficient in the manufacturing and quality control processes necessary for producing high-quality hydraulic hoses.

Technological Advancements

china high pressure steel wire braided hydraulic hose factories

Chinese manufacturers have been at the forefront of adopting modern technologies to enhance the quality and performance of high-pressure steel wire braided hydraulic hoses. Automation in production processes, such as computer-controlled machinery, has significantly improved precision and efficiency. Moreover, continuous material innovation, including the use of advanced rubber formulations and improved wire braiding techniques, has allowed manufacturers to enhance the strength and flexibility of their hoses.

Quality control is another area where Chinese factories prioritize investments. Many manufacturers are adopting international quality standards and certifications, such as ISO9001 and SAE standards, to ensure their products meet stringent requirements in globally competitive markets.

Challenges Faced by the Industry

Despite the growth and advancements, Chinese high-pressure steel wire braided hydraulic hose factories face several challenges. One of the primary concerns is the increasing competition from other manufacturing countries, such as India and Vietnam, which are also expanding their manufacturing capabilities. These countries often offer lower labor costs and increased government incentives, making them attractive alternatives for global buyers.

Moreover, the Chinese industry is also grappling with environmental regulations. Stricter policies on emissions and waste management are impacting manufacturing processes, requiring factories to adapt quickly to sustainable practices without compromising efficiency.

Conclusion

China’s high-pressure steel wire braided hydraulic hose factories have firmly established themselves as key players in the global market, driven by technological advancements, skilled labor, and a robust supply chain. However, to maintain their competitive edge, these factories must navigate the challenges of international competition and environmental regulations effectively. As the demand for hydraulic hoses continues to grow, the adaptability and innovation of Chinese manufacturers will determine their success in the future, enabling them to meet the evolving needs of industries worldwide.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025