335345435

Nov . 24, 2024 23:18 Back to list

China Rubber Air Hose Manufacturers and Suppliers for Quality Products and Services

An Overview of China Rubber Air Hose Factories

China has established itself as a global leader in manufacturing, and one of its prominent sectors is the production of rubber air hoses. These hoses, essential for various applications ranging from industrial to domestic uses, are a vital component in pneumatic systems, providing flexibility, durability, and resistance to environmental factors. This article explores the landscape of rubber air hose factories in China, highlighting the manufacturing processes, quality standards, and market dynamics.

Manufacturing Processes

The production of rubber air hoses involves several key steps, starting with the selection of raw materials. High-quality rubber compounds are chosen for their flexibility and strength. Manufacturers often use synthetic rubber, which provides excellent resistance to heat, oil, and ozone. The mixing of these compounds is a crucial phase where additives are incorporated to enhance properties like UV resistance and longevity.

Once the rubber is prepared, it is shaped into hoses through extrusion, a process that forces the rubber through a mold to create the desired diameter and length. This method ensures uniformity and consistency across the products. After extrusion, the hoses are subjected to curing, where they are heated in a mold to facilitate chemical cross-linking, significantly improving their durability and performance.

Quality control is paramount in the production of rubber air hoses

. Factories implement rigorous testing protocols to ensure that every hose meets international standards such as ISO and ASTM. Tests for pressure resistance, flexibility, and abrasion resistance are commonplace, ensuring reliability in various applications.Quality Standards

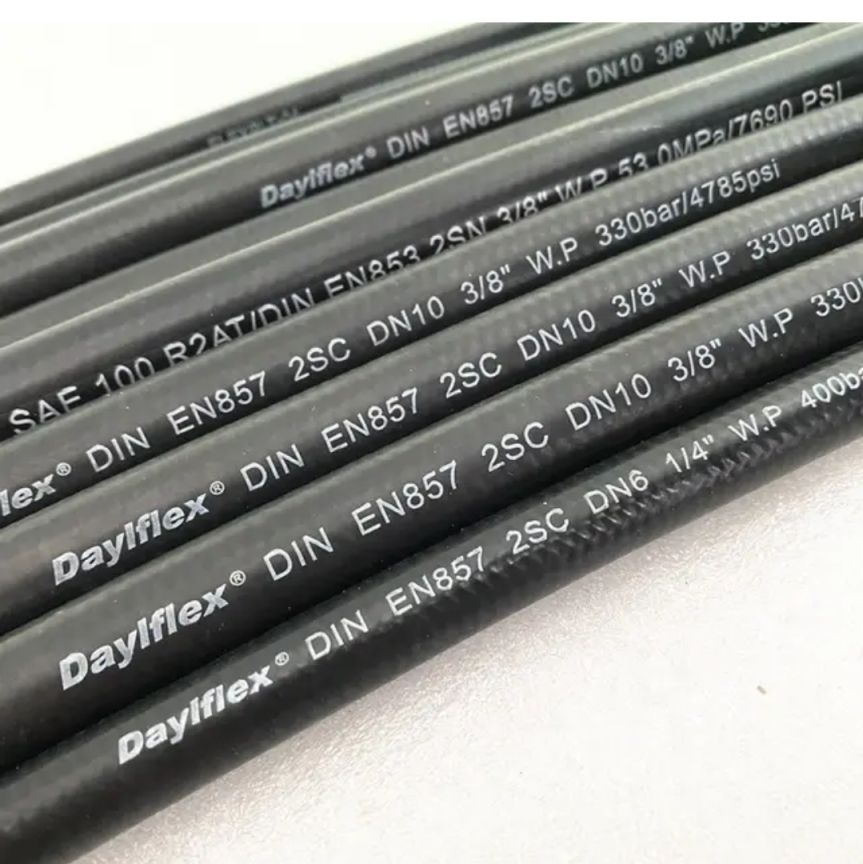

china rubber air hose factories

In an industry where safety and reliability are non-negotiable, Chinese rubber air hose manufacturers adhere to strict quality standards. Many factories have obtained certifications such as ISO 9001, indicating a commitment to quality management systems. This emphasis on quality not only meets domestic expectations but also aligns with international market requirements, allowing Chinese products to compete globally.

Furthermore, manufacturers often engage in continuous improvement practices to enhance their production processes and quality control measures. This proactive approach helps in minimizing defects and maximizing customer satisfaction, which is essential in retaining and expanding their market share.

Market Dynamics

The rubber air hose market in China has witnessed steady growth, fueled by the expansion of industries such as automotive, manufacturing, and construction. As these sectors grow, the demand for reliable pneumatic tools and equipment increases, driving the need for high-quality rubber air hoses.

China exports a significant portion of its rubber air hoses to various regions, including North America, Europe, and Southeast Asia. This international demand underscores the quality and competitiveness of Chinese manufacturers. However, challenges such as fluctuating raw material prices and increasing environmental regulations pose risks to the industry. Many factories are investing in eco-friendly manufacturing processes to address these challenges and meet the growing demand for sustainable products.

Conclusion

In conclusion, the rubber air hose industry in China plays a crucial role in the global manufacturing landscape. With advanced production techniques, strict quality standards, and a responsive approach to market demands, Chinese factories have established a reputation for producing reliable and high-quality rubber air hoses. As industries continue to evolve and expand, these manufacturers are well-positioned to adapt and innovate, ensuring their contributions to the pneumatic systems market remain significant. The future of China’s rubber air hose factories looks promising, driven by a commitment to quality, sustainability, and global partnerships.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025