335345435

Dec . 03, 2024 13:12 Back to list

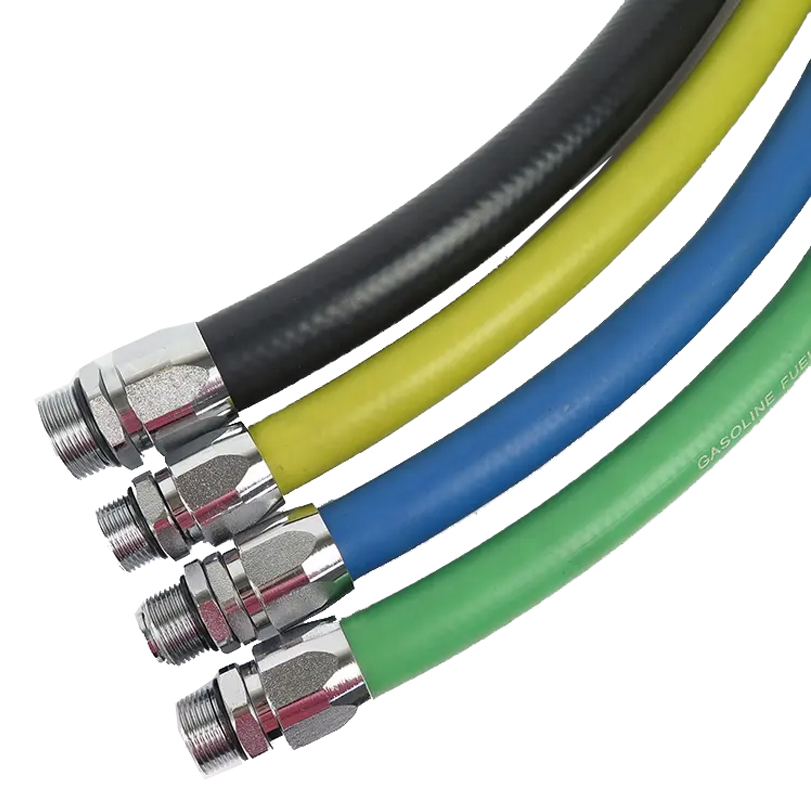

china gasoline pump hose manufacturers

The Landscape of Gasoline Pump Hose Manufacturers in China

The global landscape for gasoline pump hoses is rapidly evolving, and China has become a significant player in this niche market. As one of the largest producers and consumers of gasoline, China's manufacturing sector has adapted to meet the increasing demands of both domestic and international markets for high-quality gasoline pump hoses. This article examines the current state of gasoline pump hose manufacturing in China, the technological advancements in the industry, and the challenges that manufacturers face.

Industry Overview

China's gasoline pump hose manufacturing sector is characterized by a vast range of products catering to numerous applications. Gasoline pump hoses are critical components in fueling stations, as they are responsible for transferring fuel securely and efficiently from the dispenser to the vehicle. The demand for these hoses is fueled by the rise in automobile usage and the expansion of filling stations across urban and rural areas. China's automotive market continues to grow, with millions of new vehicles introduced yearly, leading to an increased need for fuel infrastructure.

In recent years, a growing number of manufacturers have emerged in China, ranging from small-scale local enterprises to large, well-established companies equipped with advanced production facilities. This competitive environment has resulted in a diverse product range, with hoses made from various materials, including rubber, PVC, and composite materials that offer durability, flexibility, and resistance to various chemicals.

Technological Advancements

The Chinese gasoline pump hose market has witnessed substantial technological advancements aimed at improving the efficiency and safety of fuel transfer. Manufacturers are increasingly investing in research and development to design hoses that not only meet international safety standards but also enhance user experience. Innovations such as anti-static properties in hoses, improved resistance to ozone and UV rays, and enhanced durability under extreme temperature conditions have become common.

Moreover, the integration of smart technology into gasoline pump hoses is a growing trend. Some manufacturers are beginning to incorporate sensors into their hose designs that can monitor fuel flow rates and detect leaks in real time. This not only enhances safety but also contributes to better fuel management for filling stations. Such technological innovations are crucial for minimizing environmental impact and ensuring compliance with stringent regulatory frameworks.

china gasoline pump hose manufacturers

Quality Standards and Certifications

Quality assurance is a top priority for manufacturers in China's gasoline pump hose industry. With rising global competition, Chinese companies are becoming increasingly aware that quality differentiation can be a key advantage. Many manufacturers seek certifications from international bodies such as the American Petroleum Institute (API) and Underwriters Laboratories (UL) to validate their products. These certifications ensure that the hoses can withstand rigorous testing and meet safety standards required in international markets.

In addition to obtaining certifications, manufacturers also adhere to locally enforced industry standards. The China Quality Certification Centre (CQC) is one of the prominent organizations overseeing the quality control of various products, including gasoline pump hoses. By aligning with these standards, manufacturers are not only enhancing the safety and reliability of their products but also boosting their competitiveness in the global market.

Challenges Ahead

Despite the promising growth and prospects for gasoline pump hose manufacturers in China, there are significant challenges that they face. One major concern is the increased competition from both domestic and international players. As globalization continues to shape the marketplace, manufacturers must differentiate their products and expand their value offerings to sustain their market share.

Additionally, fluctuating raw material prices and supply chain disruptions can severely impact operational efficiencies. The ongoing trade tensions and environmental regulations can also complicate trade routes and costs, forcing manufacturers to adapt quickly to remain viable.

Conclusion

In conclusion, China's gasoline pump hose manufacturing industry is at a crossroads, marked by rapid growth and technological innovation. As the country continues to develop its automotive infrastructure, the demand for quality gasoline pump hoses will undoubtedly increase. Manufacturers that can embrace innovation, maintain high-quality standards, and navigate the challenges of competition and supply chain dynamics will likely emerge as leaders in both domestic and international markets. The future of this industry looks promising, provided that stakeholders remain agile and responsive to the changing landscape.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025