335345435

Dec . 04, 2024 10:14 Back to list

China Forklift Hydraulic Hose Manufacturing and Supply Solutions

Understanding the Hydraulic Hose in China's Forklift Manufacturing Industry

In recent years, China's manufacturing sector has witnessed exceptional growth, especially in the production of industrial equipment such as forklifts. Among the vital components that ensure the efficient operation of these machines are hydraulic hoses. This article will explore the role of hydraulic hoses in forklifts, the manufacturing process in Chinese factories, and the significance of quality in maintaining operational excellence.

The Role of Hydraulic Hoses in Forklifts

Hydraulic hoses are indispensable in the functionality of forklifts. These hoses are responsible for transmitting hydraulic fluid, which powers various critical components of the forklift, including the lift mechanism, steering, and brakes. The efficiency and effectiveness of a forklift are significantly influenced by the quality of its hydraulic system, and in this system, the performance of the hydraulic hoses plays a crucial role.

In simple terms, hydraulic hoses act as the veins of the forklift, facilitating the flow of hydraulic fluid throughout the machinery. When a forklift operator lifts a load, the hydraulic pump generates pressure that travels through these hoses to move the hydraulic cylinder, enabling the fork to elevate the cargo. Consequently, reliable and durable hydraulic hoses are paramount for safe and efficient forklift operation.

Manufacturing Process in China’s Hydraulic Hose Factories

China has established itself as a global hub for industrial manufacturing, thanks to its skilled workforce, advanced technology, and competitive pricing

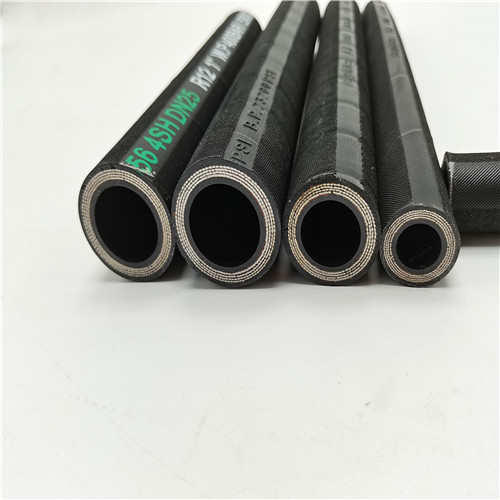

. The production of hydraulic hoses is a specialized process that requires precision and quality control at every stage.1. Material Selection The first step in manufacturing hydraulic hoses is selecting the appropriate materials. Typically, hoses are made from high-quality synthetic rubber, which is reinforced with strong fabrics and steel wire layers to enhance their durability and pressure-resistance capabilities.

2. Extrusion and Braiding The rubber is extruded into tubular shapes, allowing for the creation of hoses of various diameters and lengths. In many cases, a braiding process is utilized, where wire is woven around the hose to provide additional strength, crucial when high pressure is applied.

china forklift hydraulic hose factory

3. Curing After the hoses are formed, they go through a curing process in which heat is applied. This step is essential for vulcanizing the rubber, making it more resilient and heat-resistant.

4. Testing Quality assurance is critical in hydraulic hose production. Hoses undergo rigorous testing to ensure they can withstand intense pressure and temperature changes. Manufacturers frequently perform burst tests, impulse tests, and leak tests to verify the integrity of the hoses before they are approved for use in forklifts.

5. Final Assembly The last stage involves assembling the hoses with the necessary fittings and connectors that enable them to be attached to the forklift's hydraulic system seamlessly.

Significance of Quality Assurance

In an industry where safety is paramount, quality assurance of hydraulic hoses cannot be overstated. Poorly manufactured hydraulic hoses can lead to catastrophic failures, resulting in accidents, equipment damage, and financial losses. Thus, forklift manufacturers often prioritize sourcing hydraulic hoses from reputable factories that adhere to international standards and certifications.

Quality hydraulic hoses not only contribute to the safety of operations but also enhance the overall operational efficiency of the forklifts. Reliable performance means less downtime for repairs and maintenance, positively impacting productivity in warehouses and manufacturing facilities.

Conclusion

The hydraulic hose is a critical component in the functioning of forklifts, and its production in China's factories reflects the ongoing advancements in industrial manufacturing. With a robust process in place to ensure quality and reliability, China's hydraulic hose manufacturers are set to continue their role as global leaders in this sector. As the demand for forklifts continues to grow, particularly in the e-commerce and logistics industries, the importance of high-quality hydraulic hoses will only become more pronounced. Therefore, investments in this aspect of forklift production will have lasting effects on operational efficiency and safety in the industrial landscape.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025