335345435

Dec . 04, 2024 20:23 Back to list

Top Manufacturers of Hydraulic Hose Fittings in China for Reliable Solutions

The Evolution and Importance of Hydraulic Hose Fittings in China

In recent years, China has emerged as a global powerhouse in manufacturing, particularly in the field of hydraulic components. Among these components, hydraulic hose fittings play a crucial role in various industries including construction, agriculture, and machinery. The combination of advanced manufacturing techniques, a skilled workforce, and substantial investment in technology has positioned China as a leading supplier in the hydraulic hose fittings market.

Understanding Hydraulic Hose Fittings

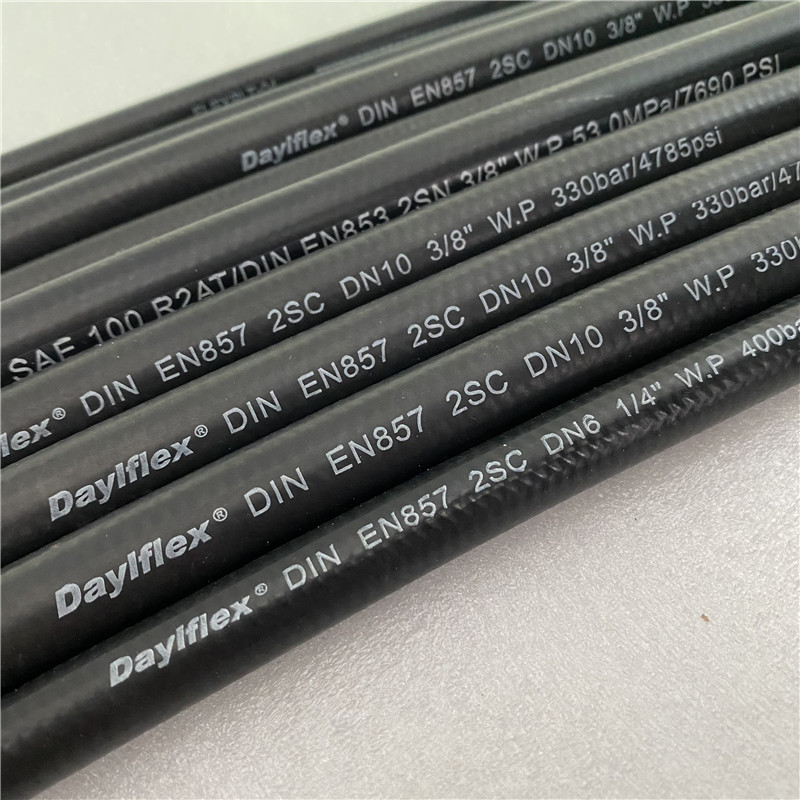

Hydraulic hose fittings are essential components connecting hoses to pumps, valves, actuators, and other fluid-conveying equipment. They are designed to ensure a leak-proof and secure connection, which is vital for maintaining the efficiency and safety of hydraulic systems. These fittings come in various shapes and sizes, crafted from materials like steel, brass, and polymers, to cater to different pressure and temperature requirements.

The Chinese Manufacturing Landscape

The manufacturing ecosystem in China has evolved dramatically over the past few decades. As one of the largest producers of hydraulic hose fittings, Chinese manufacturers leverage cutting-edge technology alongside traditional craftsmanship. This combination allows them to produce fittings that meet international standards while offering competitive pricing.

Chinese manufacturers employ advanced production techniques such as Computer Numerical Control (CNC) machining, which enables high precision and efficiency. Automated assembly lines and rigorous quality control processes further ensure that every fitting produced meets stringent quality and performance standards. This technology adoption not only enhances productivity but also reduces waste, making the manufacturing processes more sustainable.

Quality Assurance and Standards

china china hydraulic hose fittings manufacturers

Quality assurance is paramount in the production of hydraulic hose fittings. Manufacturers in China are increasingly adopting international quality standards, such as ISO 9001 and SAE J516, to ensure their products are reliable and safe for usage. Many companies are also acquiring certifications such as CE and RoHS, which signify compliance with European directives. This commitment to quality has earned Chinese manufacturers a solid reputation in global markets.

Market Trends and Innovations

The demand for hydraulic hose fittings continues to grow, driven by the expansion of industries such as construction, mining, and agriculture. Innovative applications of hydraulic systems in these sectors require advanced fittings capable of withstanding extreme pressures and environments. As a response, Chinese manufacturers are investing in research and development to create more durable, efficient fittings.

Some notable trends include the development of lightweight materials, which offer improved handling and installation while maintaining strength. Additionally, manufacturers are exploring the use of environmentally friendly materials and processes, reflecting a growing awareness of sustainability in manufacturing practices.

Challenges and Opportunities

Despite the robust growth, the hydraulic fittings industry in China faces challenges, including fierce competition and fluctuating raw material costs. However, these challenges also present opportunities for innovation. Companies that can adapt to market changes and invest in R&D are likely to outpace their competitors. Furthermore, the increasing global demand for high-quality hydraulic components creates a promising avenue for growth.

Conclusion

In conclusion, the landscape of hydraulic hose fittings manufacturing in China is characterized by rapid technological advancements and a commitment to quality. As industries worldwide continue to evolve, the importance of reliable and efficient hydraulic systems becomes increasingly evident. Chinese manufacturers are well-positioned to meet this demand, providing innovative solutions that not only enhance the performance of hydraulic systems but also contribute to sustainable practices in manufacturing. With ongoing investments in technology and quality assurance, the future of hydraulic hose fittings in China looks not only promising but also pivotal for global industrial growth.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025