335345435

Dec . 05, 2024 14:28 Back to list

china braided ptfe hose manufacturers

The Rise of Braided PTFE Hose Manufacturers in China

In recent years, China has emerged as a global leader in the manufacturing of a wide range of industrial products, and braided PTFE (Polytetrafluoroethylene) hoses are no exception. Known for their exceptional durability, chemical resistance, and high-temperature performance, braided PTFE hoses have become an essential component in various industries, including automotive, aerospace, pharmaceuticals, and food processing. This article explores the factors contributing to the growth of braided PTFE hose manufacturers in China and their impact on the global market.

The Advantages of Braided PTFE Hoses

Braided PTFE hoses offer several advantages over traditional rubber hoses. Firstly, they are highly resistant to a wide range of chemicals, making them suitable for transporting corrosive fluids and gases. This chemical inertness is critical in industries like pharmaceuticals and food processing, where contamination can have severe consequences. Secondly, PTFE hoses can withstand high temperatures, withstanding conditions that would damage standard rubber hoses. This thermal stability is particularly important in applications involving steam or hot liquids.

Moreover, the braided construction of these hoses enhances their structural integrity, providing additional strength and flexibility. The external braid, usually made from stainless steel, serves as a protective layer, preventing abrasion and external damage. This combination of features has made braided PTFE hoses the preferred choice for many engineers and procurement professionals seeking reliable and durable solutions.

China's Manufacturing Landscape

China's dominance in the manufacturing sector is backed by several key advantages. The country boasts a well-developed industrial infrastructure, a vast workforce, and an array of advanced manufacturing technologies. This environment allows for the mass production of high-quality braided PTFE hoses at competitive prices.

Furthermore, China's commitment to innovation and technology adoption has propelled the manufacturing processes of braided hoses to new heights. Many manufacturers are investing in research and development to improve the performance characteristics of PTFE hoses, exploring new materials, and optimizing production techniques. This focus on continuous improvement ensures that Chinese manufacturers can meet the evolving needs of their international clients.

china braided ptfe hose manufacturers

Export Opportunities and Global Reach

As the demand for braided PTFE hoses continues to rise globally, Chinese manufacturers have strategically positioned themselves to capture a significant share of the market. Export opportunities are abundant, with many countries seeking reliable suppliers who can provide high-quality products at competitive prices. Consequently, manufacturers in China actively engage in international trade, participating in trade shows and forming partnerships with distributors in various regions.

The ability to meet international quality standards, such as ISO certifications, has further enhanced the reputation of Chinese braided PTFE hose manufacturers. These certifications reassure customers of the reliability and safety of their products, making them a preferred choice for global clients.

Challenges and Future Prospects

Despite their growth and success, Chinese manufacturers of braided PTFE hoses face challenges. Fluctuating raw material prices, environmental regulations, and intense competition from both domestic and international players pose risks to profit margins and market share. Additionally, as global standards for quality and sustainability continue to evolve, manufacturers must adapt to these changes to remain competitive.

Looking ahead, the future of braided PTFE hose manufacturing in China appears bright. With ongoing investments in technology and innovation, manufacturers are likely to enhance their product offerings further. The growing focus on sustainability and eco-friendly practices will also shape the industry's landscape, pushing companies to adopt greener manufacturing processes.

Conclusion

The emergence of braided PTFE hose manufacturers in China marks a significant development in the global industrial market. Their ability to produce high-quality, durable, and chemically resistant hoses has positioned them as key players in various industries. As the demand for innovative and reliable solutions continues to grow, Chinese manufacturers are well-equipped to meet the needs of international markets and drive the industry forward. With a focus on quality, technology, and sustainability, the future of braided PTFE hoses made in China looks promising.

-

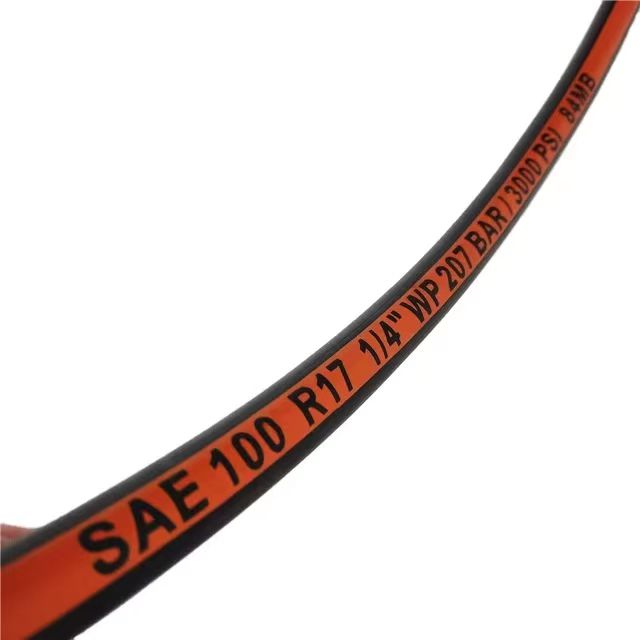

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025