335345435

Sep . 15, 2024 15:42 Back to list

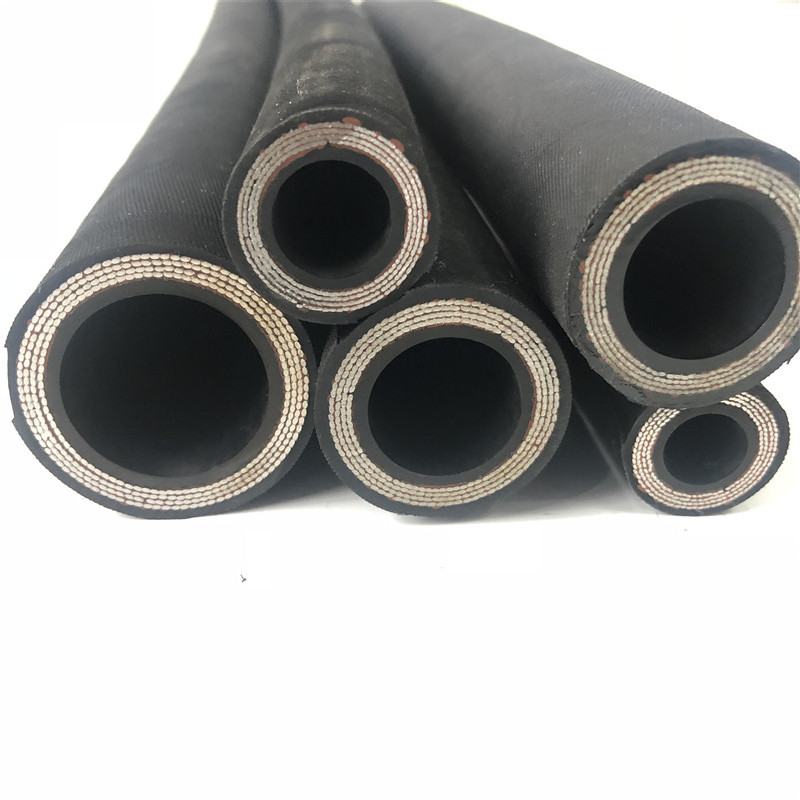

High-Quality Steel Braided Hydraulic Hose Manufacturers in China

China Steel Braided Hydraulic Hose Manufacturers An Overview

The hydraulic hose industry plays a vital role in various sectors, such as construction, manufacturing, and automotive, where hydraulic systems require reliable and efficient fluid transfer solutions. Among these, steel braided hydraulic hoses have gained popularity due to their robust construction, flexibility, and resistance to high pressures and extreme conditions. China has emerged as a key player in the global market for steel braided hydraulic hoses, boasting numerous manufacturers that cater to diverse industrial needs.

Manufacturing Landscape in China

China's hydraulic hose manufacturing sector is characterized by a large number of companies ranging from small-scale producers to large corporations. These manufacturers benefit from the country's vast industrial ecosystem, where raw materials, skilled labor, and advanced technology converge. The growth of the hydraulic hose market in China is attributed to increasing infrastructure development, industrialization, and the expansion of the petrochemical industry, all of which demand high-performance hydraulic solutions.

Design and Specifications

Steel braided hydraulic hoses are engineered to withstand high pressure and are commonly used in applications where fluid transfer is critical. These hoses are constructed with multiple layers of reinforcement, including steel wires that provide additional strength and durability. The most common types of steel braided hydraulic hoses include single and double braid versions, each suited to different pressure ratings and applications. Manufacturers in China are committed to adhering to international quality standards, ensuring that their products can compete in global markets.

Innovations and Advancements

china steel braided hydraulic hose manufacturers

Chinese manufacturers are embracing innovation to improve the performance and longevity of steel braided hydraulic hoses. Advanced manufacturing techniques, such as automated weaving and high-temperature curing processes, are being employed to enhance product quality. Additionally, some companies are investing in research and development to create hoses with better abrasion resistance, lower weight, and enhanced flexibility. This focus on innovation enables Chinese manufacturers to meet the evolving demands of various industries and maintain a competitive edge.

Quality Assurance and Compliance

Quality is paramount in the production of hydraulic hoses, as failures can lead to severe consequences in operational environments. Chinese manufacturers often implement rigorous quality control measures throughout the production process, including testing for pressure ratings, burst strength, and chemical compatibility. Many companies obtain certifications from international standards organizations, such as ISO and SAE, to demonstrate their commitment to quality and safety. These certifications not only bolster consumer confidence but also facilitate access to global markets.

The Future of Hydraulic Hose Manufacturing in China

As the demand for efficient and reliable hydraulic solutions continues to grow globally, the future of steel braided hydraulic hose manufacturing in China looks promising. With ongoing investments in technology, increasing automation, and a strong focus on sustainability, Chinese manufacturers are well-positioned to lead in the global market. By prioritizing quality, innovation, and customer satisfaction, they can cater to various industries and contribute significantly to the global supply chain.

Conclusion

In summary, China’s steel braided hydraulic hose manufacturers play a crucial role in meeting the demands of modern industries. Their commitment to quality, innovation, and compliance with international standards ensures that they remain competitive on the global stage. As industrial needs evolve, these manufacturers will likely continue to adapt and expand, solidifying China’s position as a key supplier of hydraulic solutions worldwide.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025