335345435

Dec . 04, 2024 18:20 Back to list

chemical ptfe hose manufacturers

Understanding Chemical PTFE Hose Manufacturers Key Insights

In various industries, the demand for specialized hoses has skyrocketed. Among these, chemical PTFE (Polytetrafluoroethylene) hoses have gained a significant foothold due to their remarkable properties, making them an ideal choice for transporting chemicals, gases, and other potentially harmful substances. This article delves into the intricacies of chemical PTFE hose manufacturers, exploring their products, significance, and what to consider when choosing a supplier.

What Are Chemical PTFE Hoses?

PTFE hoses, often referred to by their brand name Teflon, are designed to handle challenging chemical processes. Their unique characteristics include high thermal stability, low friction, and exceptional chemical resistance. PTFE is non-reactive and can withstand extreme temperatures, making it suitable for transporting aggressive chemicals such as acids, solvents, and bases without degradation. This property is crucial in industries such as pharmaceuticals, food processing, chemicals, and petrochemicals, where the integrity of the transport medium directly affects product quality and safety.

The Role of Manufacturers

Chemical PTFE hose manufacturers play a critical role in ensuring that industries have access to high-quality products that meet rigorous safety and performance standards. These manufacturers invest in advanced technology and research to develop hoses that meet specific application needs.

1. Customization One of the primary advantages offered by many manufacturers is the ability to customize hoses according to client specifications. This could include variations in diameter, length, and even the chemistries involved. Customization ensures that hoses perform optimally in their designated applications, enhancing overall system efficiency.

2. Quality Assurance Leading PTFE hose manufacturers adhere to strict quality control processes throughout production. They often comply with international standards, such as ISO or FDA regulations, which are crucial in industries dealing with food or pharmaceuticals. This commitment to quality ensures that their hoses can withstand the rigors of their applications without failure.

3. Durability and Performance The longevity and reliability of chemical PTFE hoses depend significantly on the materials and processes used in their manufacture. Manufacturers utilize innovative bonding techniques, end fittings, and reinforcement materials to enhance durability and performance. These factors contribute to reduced maintenance costs and increased safety in operations.

4. Technical Expertise Experienced manufacturers not only produce hoses but also provide valuable technical support to their clients. They assist in selecting the right hose for specific applications, taking into account factors such as temperature, pressure, and the nature of the chemicals involved. This expertise is vital for preventing mishaps and ensuring efficient operations.

chemical ptfe hose manufacturers

Choosing the Right Manufacturer

When selecting a chemical PTFE hose manufacturer, companies should consider several factors

1. Reputation and Experience Research the manufacturer's reputation in the industry. Established manufacturers often have a track record of delivering high-quality products and services.

2. Certifications Ensure that the manufacturer complies with necessary certifications and standards relevant to your industry. This could include ISO certification, FDA approval for food-safe applications, or other relevant health and safety standards.

3. Customization Capabilities Evaluate whether the manufacturer can cater to your specific needs through customized hoses. A manufacturer that offers tailored solutions is often more capable of addressing unique challenges presented by particular applications.

4. Customer Support Quality after-sales service is crucial. A manufacturer that provides exceptional customer support can help resolve issues promptly and assist with ongoing maintenance and performance monitoring.

5. Innovation and Technology Look for manufacturers that invest in research and development. Cutting-edge technology often translates into better-performing products, bringing efficiency and safety to operations.

Conclusion

Chemical PTFE hoses are essential components in industries that handle aggressive chemicals. The role of PTFE hose manufacturers extends beyond simple production; they are pivotal in ensuring safety, reliability, and compliance with industry standards. By considering factors such as reputation, customization, and technical support, businesses can make informed decisions when selecting a manufacturer that meets their needs. As industries continue to evolve, so too will the innovations in hose manufacturing, reinforcing the importance of these specialized products in our daily operations.

-

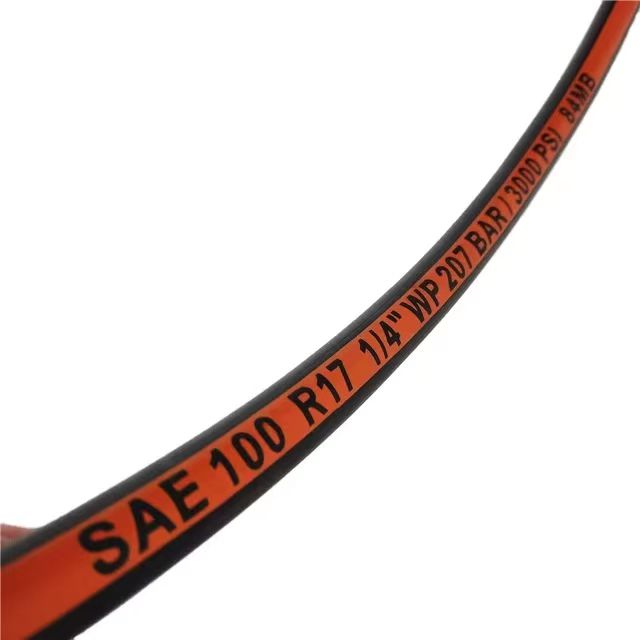

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025