335345435

Dec . 04, 2024 08:15 Back to list

5mm Hydraulic Hose Manufacturing Process and Quality Standards Overview

The Emergence of 5mm Hydraulic Hose Factories An Overview of the Industry

In the world of industrial applications, hydraulic hoses play a critical role in ensuring the efficient transfer of fluids. Among various sizes and types, the 5mm hydraulic hose has gained substantial popularity due to its versatility and effectiveness in numerous operations. This article explores the significance of 5mm hydraulic hose factories, their manufacturing processes, and the broader implications for the hydraulic industry.

Understanding Hydraulic Hoses

Hydraulic hoses are specially designed to carry hydraulic fluid, which is essential for the operation of hydraulic systems. These hoses must withstand high pressure and temperature, making the choice of materials and construction techniques crucial. Generally made from synthetic rubber, thermoplastic, or steel, these hoses come in various sizes, with the 5mm diameter emerging as a preferred option in many applications. This size is particularly favored in scenarios where space is a premium yet adequate fluid transfer performance is required, such as in small machinery and automotive applications.

The Growth of 5mm Hydraulic Hose Factories

The establishment of dedicated factories for 5mm hydraulic hoses marks a significant trend in the manufacturing sector. As industries ranging from agriculture to construction increasingly rely on hydraulic systems, the demand for specific hose sizes has surged. As a result, factories specializing in 5mm hoses have proliferated, driven by the need for high-quality, durable products.

These factories utilize advanced technology to produce hoses that meet stringent safety and performance standards. Modern manufacturing processes involve a combination of automated machinery and skilled labor, ensuring efficiency and precision. The production line typically includes steps such as raw material selection, extrusion, reinforcement, and quality control.

Manufacturing Process

The production of 5mm hydraulic hoses begins with the careful selection of raw materials. High-quality synthetic rubber or thermoplastic is chosen for its durability and flexibility. The materials are then extruded into the desired hose shape, after which reinforcement materials, such as steel wire or textile fibers, are woven into the structure to enhance strength.

5mm hydraulic hose factory

Next, the hoses undergo vulcanization, a process that involves heating the rubber to improve its durability and resistance to damage. This step is crucial, as it creates a strong bond between the internal and external layers of the hose, allowing it to withstand high pressures without bursting.

Once the hoses are produced, they undergo rigorous quality control tests. These tests include pressure testing to ensure the hoses can handle the desired pressure levels, as well as inspections for any manufacturing defects. Only hoses that pass these stringent checks are sent out for distribution, ensuring that customers receive reliable products.

Environmental Considerations

With the rise of 5mm hydraulic hose factories, there is an increasing focus on sustainability and environmental protection. Many factories are adopting eco-friendly practices in their operations, such as recycling scrap material and minimizing waste during production. Additionally, advancements in material science have led to the development of more environmentally friendly hose materials that do not compromise performance.

Market Dynamics and Future Trends

The market for 5mm hydraulic hoses is expected to continue growing as industries seek efficient and compact solutions for hydraulic applications. Factors driving this growth include advancements in hydraulic technology, an increase in construction and agricultural activities, and the rising popularity of compact machinery that requires smaller hoses.

Furthermore, the trend toward automation and smart technology in manufacturing processes will likely enhance the efficiency and precision of 5mm hydraulic hose production. As factories embrace Industry 4.0 principles, the integration of IoT devices and AI analytics will optimize production schedules and maintain stringent quality control.

Conclusion

The establishment of 5mm hydraulic hose factories represents a significant development in the hydraulic industry, reflecting the ongoing need for specialized manufacturing capabilities. As these factories continue to evolve through technological advancements and a commitment to sustainability, they will play a crucial role in supporting various sectors that rely on hydraulic systems. By prioritizing quality, efficiency, and environmental stewardship, the 5mm hydraulic hose industry is poised for a bright future.

-

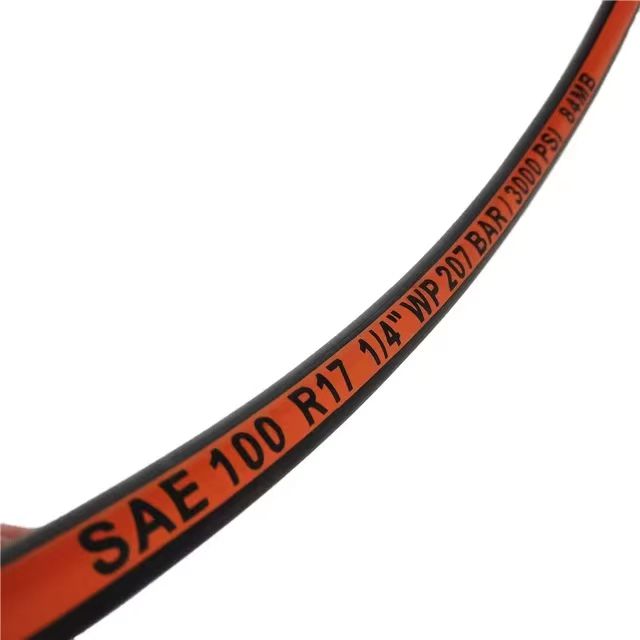

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025