335345435

Oct . 14, 2024 14:27 Back to list

5/8 Inch Hydraulic Hose Manufacturing Solutions for Quality Performance and Reliability

The Importance of 5/8% Hydraulic Hose Factories in Modern Industry

In the rapidly evolving world of industrial machinery, hydraulic hoses play an essential role in the efficient and safe operation of various equipment. Among the various sizes and types of hydraulic hoses, the 5/8-inch hydraulic hose stands out due to its versatility and functionality. This article explores the significance of 5/8-inch hydraulic hose factories in the broader context of industrial operations, their production processes, quality control measures, and the future of hydraulic hose manufacturing.

The Role of Hydraulic Hoses

Hydraulic hoses are integral components of hydraulic systems, which utilize pressurized fluid to transmit energy. They are employed in numerous applications, including construction machinery, agricultural equipment, and manufacturing processes. The 5/8-inch hydraulic hose is particularly favored for its balance between flexibility and durability, making it suitable for various high-pressure applications.

These hoses are designed to withstand the demands of tough environments while maintaining their integrity. Their construction generally involves multiple layers, including a rubber inner tube, a steel wire reinforcement layer, and an outer covering that provides protection against abrasion, weather elements, and other external factors.

The Functionality of 5/8-Inch Hydraulic Hose Factories

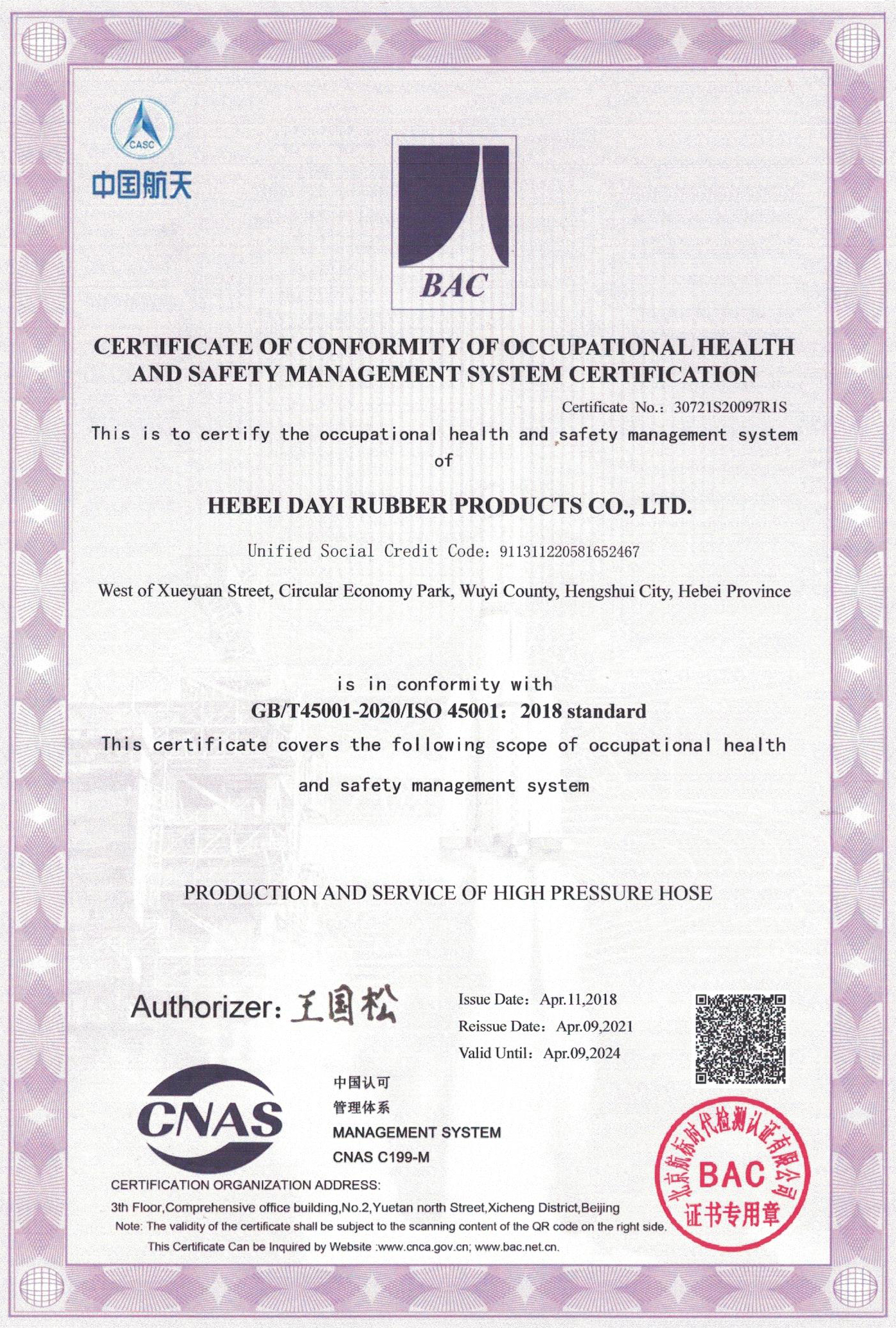

5/8-inch hydraulic hose factories specialize in the production of these essential components, drawing on advanced manufacturing techniques and state-of-the-art technology. To ensure high-quality output, these factories often employ skilled technicians and engineers who oversee the entire manufacturing process, from material selection to hose assembly.

The production process begins with sourcing high-grade raw materials, primarily influenced by the intended application of the hose. Factories must ensure that the materials meet stringent industry standards for chemical resistance, pressure tolerance, and temperature adaptability. Once the materials are procured, they are subjected to a rigorous manufacturing process that includes extrusion, braiding, and vulcanization, creating a robust final product.

Quality Control and Testing

5/8 hydraulic hose factory

Quality control is a critical aspect of any reputable hydraulic hose factory. With failure of hydraulic hoses potentially leading to serious equipment malfunctions and serious safety hazards, comprehensive testing protocols are established to guarantee the reliability of the products. These factories implement various testing procedures, including

1. Pressure Testing This simulates the working conditions the hose will encounter, ensuring it can withstand the necessary pressures without failure. 2. Flexibility Testing Hydraulic hoses must maintain flexibility to allow for installations in confined spaces. This test ensures that the hose can bend without developing kinks or leaks.

3. Durability Testing Factories also conduct accelerated aging tests to assess the long-term performance of hoses subjected to extreme conditions.

4. Chemical Resistance Testing Given that hydraulic fluids come in various compositions, it is crucial to test how well a hose can resist degradation when exposed to these chemicals.

The Future of Hydraulic Hose Manufacturing

As the demand for advanced machinery and equipment grows, the need for high-performance hydraulic hoses, including 5/8-inch variants, is expected to rise. Innovations in manufacturing materials, such as high-strength synthetic fibers and improved rubber compounds, will likely enhance the operational capabilities of hydraulic hoses. Additionally, factories are beginning to adopt smart manufacturing practices, integrating IoT (Internet of Things) technologies to monitor production processes in real-time for increased efficiency and reduced waste.

Moreover, as industries evolve towards sustainability, hydraulic hose factories are also focusing on environmentally friendly manufacturing processes. Initiatives to recycle materials and reduce energy consumption during production will not only help the environment but also appeal to a growing market of eco-conscious consumers.

Conclusion

The operations of 5/8-inch hydraulic hose factories are crucial to the success of various industries, exemplifying the convergence of technology, quality, and safety in manufacturing. As industrial demands continue to evolve, these factories will play an increasingly important role in developing and supplying hydraulic hoses that meet the rigorous standards required for modern machinery. Their commitment to quality assurance, innovative practices, and forward-thinking approaches positions them as vital contributors to the future of industrial operations.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025