335345435

Oct . 18, 2024 11:04 Back to list

Top Manufacturers of 3/8 Inch Hydraulic Hoses for Reliable Fluid Transfer Solutions

Understanding 3/8% Hydraulic Hose Manufacturers

Hydraulic hoses are vital components in various industrial applications, serving the critical function of transferring fluid to power hydraulic machinery. Among the myriad sizes and specifications available in the market, the 3/8 inch hydraulic hose stands out due to its versatility and effectiveness. This article delves into the significance of 3/8 inch hydraulic hose manufacturers, exploring their role in the industry, the key factors to consider when choosing a manufacturer, and the future trends in hydraulic hose production.

The Role of Hydraulic Hose Manufacturers

Hydraulic hoses are engineered to withstand high pressures, making them ideal for fluid transfer in environments where traditional hoses might fail. Manufacturers of these hoses must adhere to stringent safety and quality standards to ensure reliability and durability. The 3/8 inch hydraulic hose is popular in various industries, including construction, agriculture, and automotive, where hydraulic systems play a crucial role in machinery operation.

Manufacturers specialize in designing hoses that cater to specific applications. For instance, a 3/8 inch hydraulic hose might be used in a compact excavator, where limited space and high pressure necessitate a robust solution. Manufacturers often focus on creating products that are not only suited for high-pressure systems but also resistant to abrasion, environmental factors, and chemicals, ensuring longevity and performance.

Key Considerations When Choosing a Manufacturer

When selecting a manufacturer for 3/8 inch hydraulic hoses, several factors should be considered to ensure quality and reliability

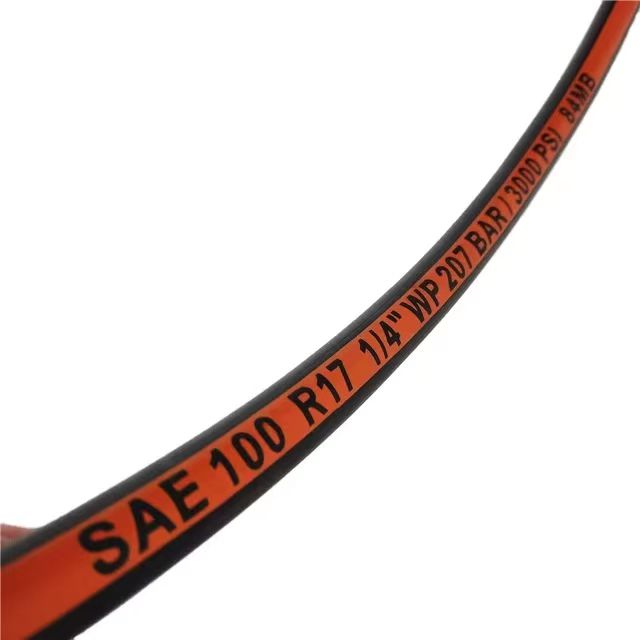

1. Certification and Standards Compliance Reliable manufacturers comply with international standards such as ISO, SAE, and ASTM. Certifications indicate a commitment to quality and safety, which is essential for hydraulic applications.

2. Material Quality The materials used in manufacturing hydraulic hoses directly impact their performance. High-quality materials resist wear and tear, temperature fluctuations, and exposure to various fluids. Ensure the manufacturer sources premium rubber or thermoplastic materials for their hoses.

3. Customization Options Different applications may require specific features, such as additional reinforcements or unique fittings. A good manufacturer should offer customization options to accommodate varying needs.

3/8 hydraulic hose manufacturers

4. Reputation and Experience Researching a manufacturer’s reputation within the industry can provide insights into their reliability. Established manufacturers often have a proven track record and positive reviews from clients.

5. Customer Support and Service A responsive customer service team can facilitate a smoother purchasing process. Manufacturers that offer technical support and guidance are valuable, especially for businesses that may require assistance in selecting the right products.

6. Pricing and Warranty Pricing should reflect the quality of the hose. While it might be tempting to choose the cheapest option, it’s essential to consider the long-term value. Additionally, a good warranty can provide peace of mind regarding the product’s lifespan.

Trends in Hydraulic Hose Manufacturing

As technology continues to evolve, the hydraulic hose manufacturing industry is not left behind. One significant trend is the integration of advanced materials and construction techniques. For instance, manufacturers are exploring lightweight, high-strength thermoplastic hoses that offer flexibility and resistance to harsh environments, which can enhance efficiency in various applications.

Moreover, sustainability is becoming a focal point for many manufacturers. There is a growing emphasis on producing hoses using environmentally friendly materials and processes. This shift not only meets regulatory requirements but also aligns with the increasing demand from consumers and businesses for sustainable practices.

In addition, the rise of automation in manufacturing processes leads to improved precision and consistency in product quality. Smart manufacturing technologies, including IoT-enabled devices and advanced analytics, are transforming how hoses are produced, monitored, and tested.

Conclusion

The significance of 3/8 inch hydraulic hose manufacturers cannot be overstated. They play a crucial role in ensuring that hydraulic systems across various industries function optimally and safely. By considering key factors such as certification, material quality, customization options, and emerging trends, businesses can make informed decisions when selecting a manufacturer. As the industry adapts to technological advancements and sustainability concerns, it is likely that the future of hydraulic hose manufacturing will be characterized by innovation and quality, ultimately benefiting end-users and the wider community.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025