335345435

Nov . 09, 2024 13:06 Back to list

Manufacturers of 16mm Hydraulic Hoses with Quality Assurance and Competitive Pricing

The Emergence and Significance of 16mm Hydraulic Hose Factories

In the ever-evolving landscape of industrial automation and machinery, hydraulic hoses play a pivotal role in ensuring the smooth operation of systems that rely on fluid power. Among the various specifications available, 16mm hydraulic hoses have gained prominence in numerous sectors, including construction, manufacturing, and agriculture. This article explores the importance of 16mm hydraulic hose factories in the global market, their manufacturing processes, and the challenges they face.

Understanding Hydraulic Hoses

Hydraulic hoses are designed to carry fluids under high pressure. Typically made from synthetic rubber, thermoplastic, or metal, they are reinforced with one or more layers of fibers or steel to withstand demanding conditions. The diameter and construction of a hydraulic hose significantly influence its application. A 16mm hydraulic hose, specifically, is suited for medium to high-pressure applications, making it ideal for machinery such as excavators, hydraulic presses, and agricultural equipment.

The Role of 16mm Hydraulic Hose Factories

1. Manufacturing and Innovation

16mm hydraulic hose factories are crucial players in the manufacturing sector. These factories leverage advanced technologies and automated processes to produce hoses that meet stringent quality standards. Several critical factors contribute to the efficacy of these factories

- Material Selection The choice of materials impacts the performance of the hoses. Factories often focus on sourcing high-quality synthetic rubber and reinforcing materials that can withstand extreme pressure and temperature variations.

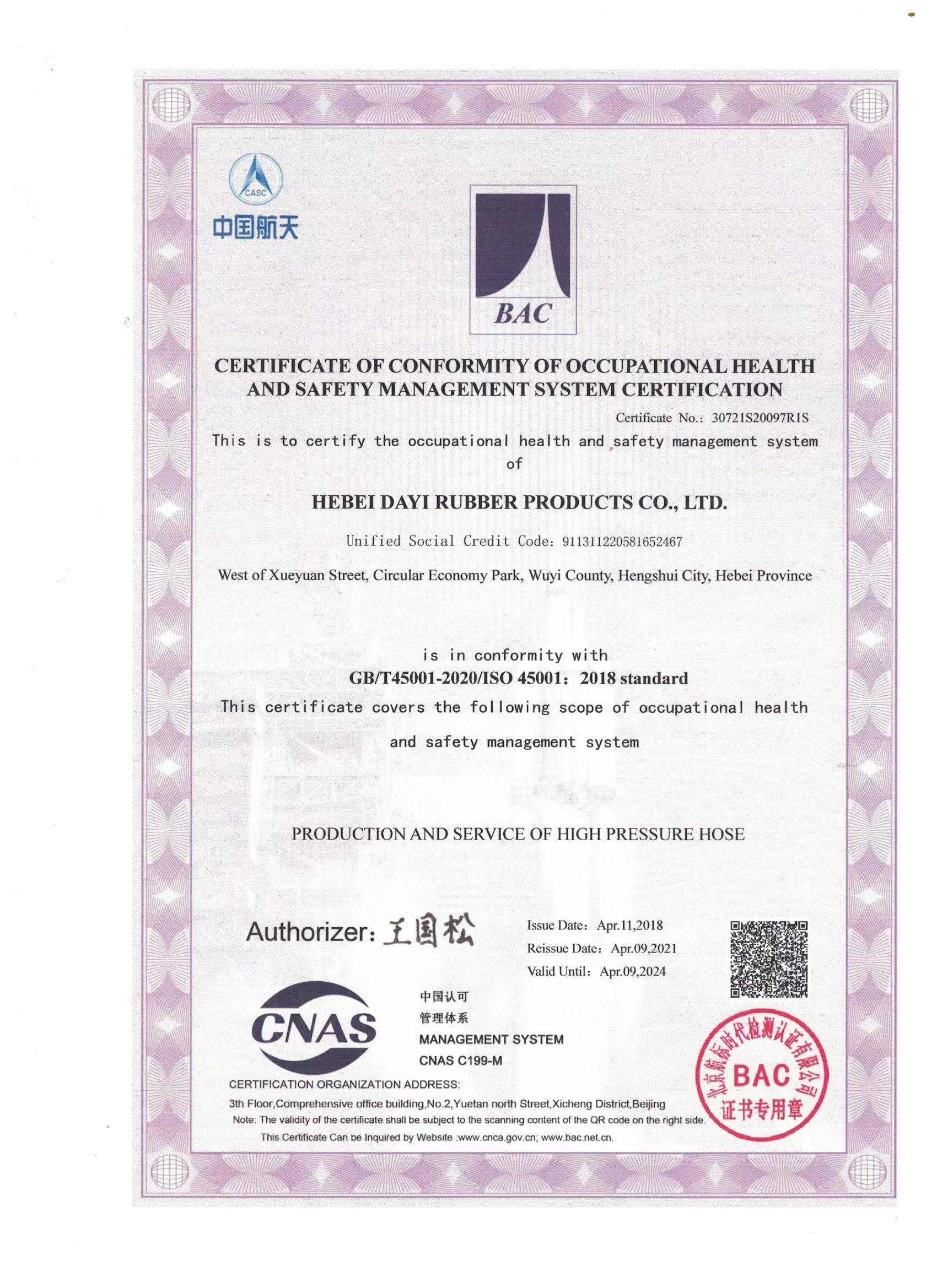

- Quality Control Rigorous quality control measures are integral to the production process. Factories conduct various tests to evaluate the pressure resistance, flexibility, and durability of the hoses. Compliance with international standards, such as ISO and SAE, is essential to ensure safety and reliability.

- Innovation With the continuous advancements in material sciences and manufacturing technologies, factories are increasingly adopting innovative methods to enhance product performance. Research and development departments focus on creating hoses that are lighter, more flexible, and resistant to external elements.

2. Meeting Market Demand

16mm hydraulic hose factories

The demand for hydraulic hoses, especially of the 16mm variety, has surged in recent years due to growing industrial activities and infrastructure development worldwide. Factories are adapting to this demand by scaling their production capabilities and offering customizable solutions to meet specific customer requirements. This flexibility allows manufacturers to cater to diverse sectors, whether it be heavy machinery for construction or specialized agricultural equipment.

As global awareness of environmental issues rises, 16mm hydraulic hose factories are increasingly incorporating sustainable practices into their operations. This includes the use of eco-friendly materials, implementing energy-efficient manufacturing processes, and establishing recycling programs for used hoses. By focusing on sustainability, these factories aim to minimize their environmental impact while meeting regulations and customer expectations.

Challenges Faced by 16mm Hydraulic Hose Factories

While the prospects for 16mm hydraulic hose factories are promising, several challenges persist

1. Increasing Competition The hydraulic hose manufacturing market is highly competitive, with numerous players vying for market share. Factories must continually innovate and enhance their product offerings to stay ahead.

2. Supply Chain Disruptions Global events, such as the COVID-19 pandemic and geopolitical tensions, have highlighted vulnerabilities in supply chains. Factories often face challenges related to raw material shortages and increased transportation costs, which can affect production timelines and pricing structures.

3. Technological Advancements Keeping pace with rapid technological advancements can be daunting. Factories must invest in new technologies and training for their workforce to remain competitive and efficient.

4. Regulatory Compliance Adhering to stringent safety and environmental regulations is imperative. Factories need to allocate resources to ensure compliance, which can increase operational costs.

Conclusion

As industries continue to evolve, the significance of hydraulic hoses, particularly 16mm varieties, will only grow. 16mm hydraulic hose factories stand at the forefront of this evolution, playing a crucial role in producing high-quality, reliable hoses that power a wide range of applications. While they face various challenges, their commitment to innovation, quality, and sustainability positions them well for the future. By adapting to market demands and embracing technological advancements, these factories will continue to drive the hydraulic hose industry into new realms of efficiency and sustainability.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025