335345435

Nov . 25, 2024 07:56 Back to list

13mm hydraulic hose factories

The Importance of 13mm Hydraulic Hose Factories in Modern Industry

In the world of modern industry, hydraulic hoses are critical components that ensure the efficient transfer of power across various types of machinery. Among these, the 13mm hydraulic hose has gained significant popularity due to its versatile applications and robust performance. Dedicated factories producing 13mm hydraulic hoses play a vital role in manufacturing these essential components, serving various sectors like construction, automotive, agriculture, and manufacturing.

The Role of 13mm Hydraulic Hoses

Hydraulic hoses are designed to withstand high pressures and extreme temperatures, making them indispensable in applications where fluids need to be transported with precision and reliability. A 13mm hydraulic hose is particularly sought after because it strikes a balance between flexibility and strength. This size allows for easy installation while maintaining the necessary durability to handle demanding tasks.

For instance, in construction, 13mm hydraulic hoses are commonly used in excavators, bulldozers, and cranes. These machines often operate in rugged environments and require hydraulic systems to function effectively. The resilience and performance of 13mm hoses ensure that these machines can operate at optimal levels without risking leaks or failures, which could lead to costly downtime.

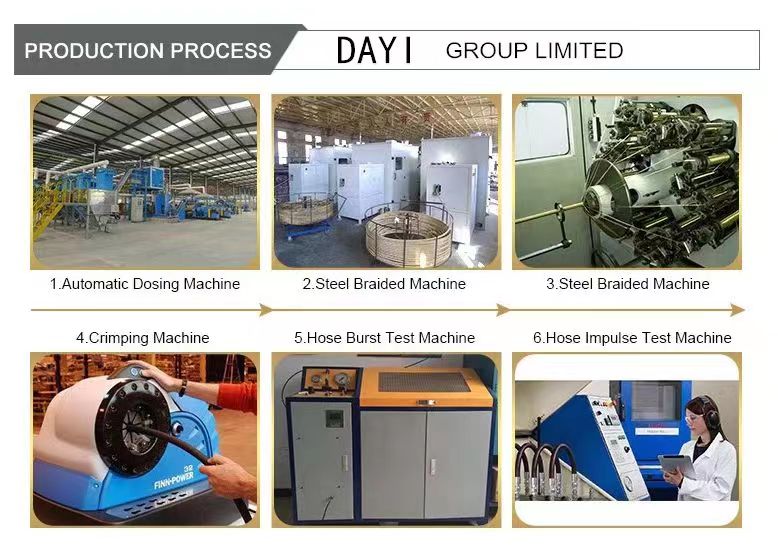

Manufacturing Processes in Hydraulic Hose Factories

The production of 13mm hydraulic hoses is a meticulous process that involves multiple steps. Factories specializing in this field utilize advanced technologies and quality materials to ensure that the end products meet stringent industry standards. The manufacturing process typically begins with sourcing high-quality raw materials such as rubber, steel wire, and synthetic fibers. The choice of materials is crucial, as they determine the hose's flexibility, pressure rating, and overall durability.

13mm hydraulic hose factories

Once the materials are procured, the production process involves several stages, including extrusion, braiding, and curing. During the extrusion process, the rubber compound is shaped into the desired form of the hose. This is followed by braiding, where steel wires are woven around the hose to provide reinforcement against high pressures. Finally, the curing process solidifies the hose, ensuring that it retains its shape and strength over time.

Quality control is a paramount concern in these factories. Each batch of hoses undergoes rigorous testing procedures, including pressure tests and temperature simulations, to guarantee that they can withstand the conditions they will face in real-world applications. Only hoses that pass these tests are deemed ready for distribution, ensuring safety and reliability for end-users.

The Impact of 13mm Hydraulic Hose Factories on the Economy

The presence of 13mm hydraulic hose factories contributes significantly to the economy by creating jobs and fostering technological advancement. These factories employ skilled workers who are trained in various aspects of manufacturing, from production to quality assurance. Additionally, they contribute to the local economy by sourcing materials from nearby suppliers, creating a ripple effect that boosts local businesses.

Moreover, as industries evolve and demand for efficient machinery increases, the need for high-quality hydraulic hoses grows. This trend drives innovation within the manufacturing sector, prompting factories to invest in research and development. As a result, new products with improved performance, longevity, and environmental sustainability are continually being introduced to the market.

Conclusion

In conclusion, 13mm hydraulic hose factories are essential pillars of modern industrial infrastructure. They not only manufacture vital components that enable machinery to function efficiently but also play a key role in supporting the economy and driving innovation. As industries continue to evolve and seek higher efficiency and reliability in their operations, the importance of specialized factories producing high-quality hydraulic hoses will only increase. The future of manufacturing not only relies on advanced technologies but also on the consistent supply of well-engineered components like the 13mm hydraulic hose, making these factories a critical aspect of industrial development.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025