335345435

Nov . 02, 2024 02:28 Back to list

100r17 hydraulic hose factory

Understanding the Significance of 100R17 Hydraulic Hose Factories

In the world of hydraulic systems, the choice of components is crucial for operational efficiency and safety. One such component is the hydraulic hose, and the 100R17 specification is a popular standard for hoses that need to withstand high pressures while maintaining flexibility and durability. This article delves into the importance of 100R17 hydraulic hose factories and the role they play in the modern industrial landscape.

What is 100R17?

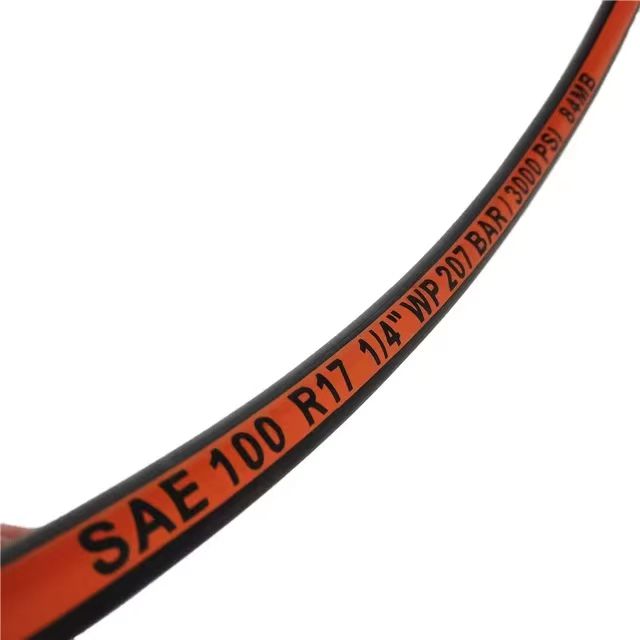

The 100R17 is a designation set by the Society of Automotive Engineers (SAE) that defines specific criteria for hydraulic hoses. A hose that meets the 100R17 specification is designed to handle high-pressure hydraulic fluids and is typically constructed from synthetic rubber, reinforced with steel wire to provide structural integrity. The ‘R’ in 100R17 denotes its classification as a rubber hose, while ‘17’ indicates its pressure rating, which can withstand up to 3,000 psi (pounds per square inch) in most configurations.

The Role of Hydraulic Hose Factories

Hydraulic hose factories that manufacture 100R17 hoses play a vital role in various industries, including construction, agriculture, and automotive. These factories are equipped with advanced machinery and technology to ensure that the hoses produced meet stringent quality and performance standards. Here are some key functions of these factories

1. Quality Assurance Factories that produce 100R17 hoses implement rigorous quality control measures throughout the manufacturing process. Raw materials are tested for durability, flexibility, and resistive properties. The final products undergo inspections to ensure they meet or exceed the SAE standards.

100r17 hydraulic hose factory

2. Customization Different applications may require specific lengths, diameters, or additional features such as heat resistance or abrasion protection. Many hydraulic hose factories offer customization options, where clients can specify their needs and have hoses tailored to their applications.

3. Supply Chain Efficiency With the growing demand for high-quality hydraulic systems, maintaining an efficient supply chain is critical. Factories need to manage inventory effectively, ensuring that they can meet the demands of various sectors without causing delays in projects.

4. Technical Support Hydraulic hose factories often provide expert advice and support to their customers. This can include selecting the right hose for a specific application, troubleshooting issues, and offering maintenance tips to prolong the lifespan of hydraulic systems.

Challenges Faced by Hydraulic Hose Factories

Despite their significant role, 100R17 hydraulic hose factories face several challenges. The increasing demand for environmentally friendly products has prompted manufacturers to invest in research and development to create hoses that have a reduced environmental impact. Additionally, competition is fierce, requiring constant innovation and operational efficiency to maintain market relevance.

Conclusion

In conclusion, 100R17 hydraulic hose factories are integral to ensuring that hydraulic systems operate effectively and safely in a variety of industries. Their commitment to quality, customization, and customer support not only enhances the performance of hydraulic systems but also contributes to the overall success of industrial operations. As technology advances and environmental considerations become paramount, these factories will continue to evolve, ensuring that they meet the ever-changing demands of the market while providing reliable and high-performing hydraulic hoses.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025