335345435

Oct . 30, 2024 20:29 Back to list

100r16 hydraulic hose factory

The Manufacturing Process of 100R16 Hydraulic Hoses

In the world of hydraulic systems, the quality and reliability of components are paramount. One such critical component is the hydraulic hose, specifically the 100R16 hydraulic hose, which is widely used in various industrial applications. Understanding the manufacturing process of these hoses not only highlights their significance but also showcases the technological advancements in the production of hydraulic components.

Overview of 100R16 Hydraulic Hoses

The 100R16 hydraulic hose is designed to handle high-pressure applications, with a rated working pressure significantly higher than that of standard hoses. It is characterized by its flexibility and durability, making it suitable for transmitting hydraulic fluids in various environmental conditions. These hoses are typically constructed from synthetic rubber and reinforced with high-tensile steel wire. This combination allows them to resist wear, abrasion, and external impacts, ensuring a long service life.

The Manufacturing Process

1. Raw Material Selection

The first step in manufacturing a 100R16 hydraulic hose is selecting high-quality raw materials. The core materials include synthetic rubber, which provides flexibility, and steel reinforcement for strength. Suppliers often source these materials from reputable manufacturers to ensure they meet industry standards.

2. Extrusion of the Inner Tube

Once the raw materials are procured, the production begins with the extrusion of the inner tube. This process involves heating the rubber compound and forcing it through a die to form a continuous tube. The inner tube must meet precise specifications to ensure optimal flow and performance of hydraulic fluids.

3. Reinforcement Layering

After the inner tube is formed, the next step is to apply the reinforcing layers. For the 100R16 specification, multiple layers of high-tensile steel wire are wound around the inner tube. This reinforcement is critical, as it prevents the hose from bursting under high pressure. The layering process is crucial and requires skilled technicians to ensure uniform coverage and tension.

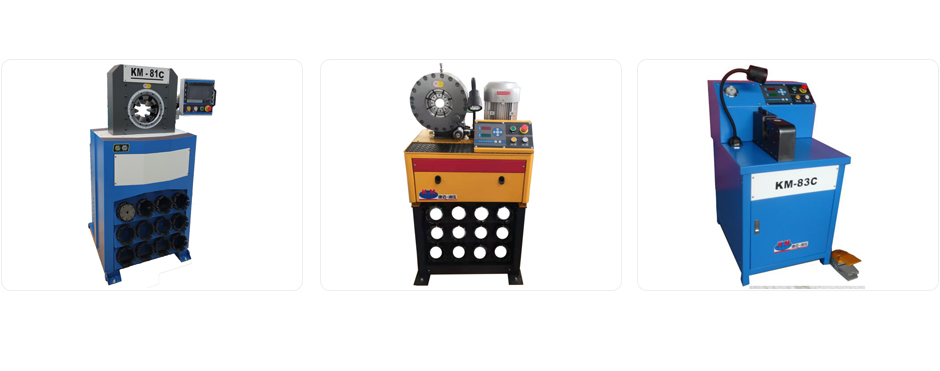

100r16 hydraulic hose factory

4. Cover Application

Following the reinforcement, a cover layer is applied to protect the hose from environmental hazards such as abrasion, UV exposure, and chemicals. The cover is often made from a specific rubber compound that enhances durability and resistance to external elements.

5. Curing Process

Once the hose is assembled, it undergoes a curing process, also known as vulcanization. This involves heating the assembled hose in an oven, which causes the rubber to harden and bond, resulting in a robust and elastic product. This step is essential for enhancing the strength and longevity of the hose.

6. Testing and Quality Control

Quality control is a critical phase in the manufacturing process. Once produced, each batch of 100R16 hydraulic hoses must undergo rigorous testing to ensure they meet specifications, including pressure ratings and durability. Tests may include hydrostatic testing, abrasion resistance testing, and dimensional inspections to ensure compliance with industry standards.

7. Packaging and Delivery

After passing quality checks, the hoses are cleaned, cut to specified lengths, and packaged for delivery. Manufacturers take special care to prepare the products for shipping, ensuring they reach customers in optimal condition.

Conclusion

The production of 100R16 hydraulic hoses is a meticulous and complex process that combines advanced technology with high-quality materials. From the selection of raw materials to rigorous testing, every stage is designed to ensure that these hoses perform reliably in demanding environments. Businesses investing in these hydraulic hoses can be assured of their durability and efficiency, making them a vital component in various industrial applications.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025