335345435

Sep . 02, 2024 14:14 Back to list

Durable 100R15 Hydraulic Hose - High-Pressure Solutions for Your Needs

The Importance of Choosing Reliable Manufacturers for 100R15 Hydraulic Hose

When it comes to hydraulic systems, the quality of the components used can significantly influence performance and safety. One critical component is the hydraulic hose, and among the various specifications available, the 100R15 hydraulic hose stands out for its robust design and high-pressure capabilities. Selecting a reputable manufacturer for this hose type is essential to ensure durability and reliability in heavy-duty applications.

Understanding 100R15 Hydraulic Hose

The 100R15 hydraulic hose is specifically designed to handle high-pressure hydraulic fluid transmission in various industries, including construction, agriculture, and mining. This hose features a robust construction, typically comprising multiple layers of steel wire reinforcement, which allows it to withstand pressures up to 6,000 psi. Its flexibility and resistance to abrasion make it suitable for challenging environments, ensuring longevity and performance.

The Role of Manufacturers

Not all hydraulic hoses are created equal, and this is where the choice of manufacturer plays a crucial role. High-quality manufacturers adhere to strict industry standards and rigorous testing protocols, ensuring their hoses meet or exceed the specifications outlined in SAE J517 for hydraulic hoses. By sourcing hoses from reliable manufacturers, users can significantly reduce the risk of hose failure, which can lead to downtime, costly repairs, and even safety hazards.

Key Considerations When Choosing a Manufacturer

100r15 hydraulic hose manufacturers

1. Reputation and Experience It's essential to select manufacturers with a proven track record in producing high-quality hydraulic hoses. Researching customer reviews and industry ratings can help gauge their reliability.

2. Certifications and Compliance Ensure that the manufacturer complies with relevant industry standards and possesses the necessary certifications. This compliance is a good indicator of their commitment to quality.

3. Materials and Technology Evaluate the materials used in the production of the 100R15 hoses. High-quality rubber compounds and steel wire are critical for performance and durability. Additionally, manufacturers using advanced technology in their production process are likely to produce superior products.

4. Customization Options Depending on the specific application, customization of hose lengths, fittings, and additional features may be necessary. A reputable manufacturer should offer these options to cater to unique requirements.

5. Customer Support and Warranty Strong customer support and a comprehensive warranty policy are indicators of a manufacturer’s confidence in their product. This support can be invaluable in case of product issues or inquiries.

Conclusion

In conclusion, when selecting a 100R15 hydraulic hose for heavy-duty applications, paying attention to the manufacturer is paramount. Choosing a reliable and experienced manufacturer not only ensures the quality and performance of the hydraulic hose but also contributes to the overall safety and efficiency of the hydraulic systems in which they are used. Investing time in research and consideration at this stage can yield significant benefits in the long run, making it a crucial step in the procurement process.

-

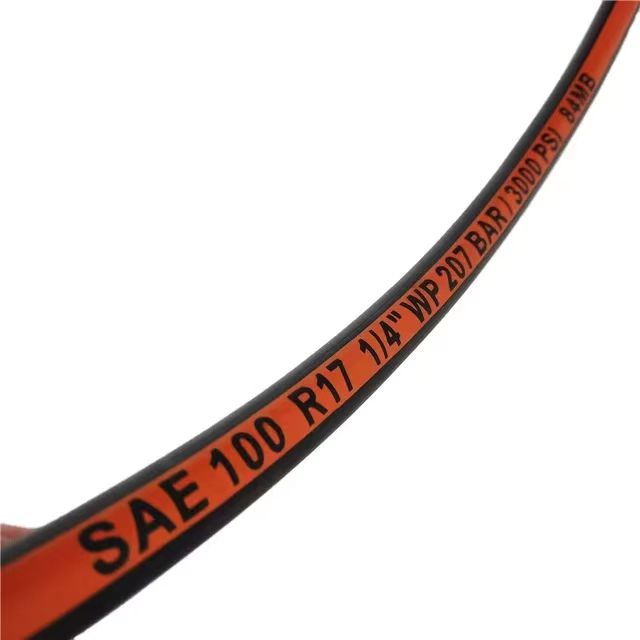

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025