335345435

Jan . 01, 2025 01:41 Back to list

OEM Four Wire Spiral Hydraulic Hose for Reliable High-Pressure Applications

Understanding OEM Four Wire Spiral Hydraulic Hoses

Hydraulic systems are crucial components in numerous industrial and mobile applications, allowing machines to transmit power and perform various functions efficiently. One key element of these systems is the hydraulic hose, which transfers fluid from one part of the system to another. Among the various types of hydraulic hoses available, the OEM four wire spiral hydraulic hose is widely recognized for its durability and performance under high-pressure conditions. This article explores the construction, applications, and benefits of four wire spiral hydraulic hoses.

Construction of Four Wire Spiral Hydraulic Hoses

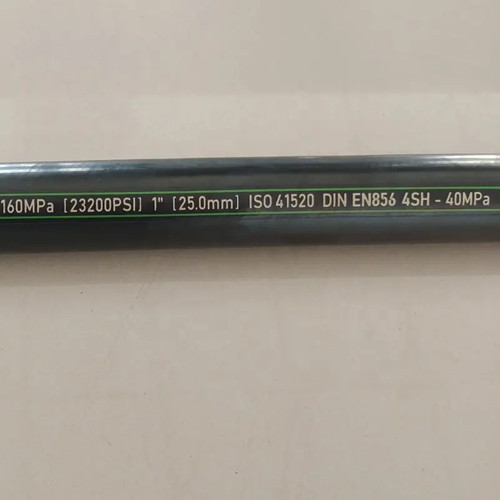

The OEM four wire spiral hydraulic hose is engineered with multiple layers to ensure robustness and flexibility. Unlike standard hoses that may use textile braiding, four wire spiral hoses utilize four layers of high tensile steel wire spirals. This construction provides exceptional strength to withstand high working pressures and prevents burst failures. The primary components of a four wire spiral hydraulic hose include

1. Inner Tube The inner lining is made from synthetic rubber designed to resist the action of hydraulic fluids. It is crucial that this material is compatible with the specific fluid being transported.

2. Reinforcement Layers The four layers of spiral wire reinforcement are pivotal. They create a robust structure capable of withstanding pressures that can exceed 4000 PSI, depending on the hose's specifications. This spiraled design minimizes the chance of premature failure due to crushing or bending.

3. Outer Cover The outer cover is designed to protect the hose from abrasions, environmental factors, and exposure to different chemicals. Materials used in the outer layer are often resistant to oil, weather, and sunlight.

4. Quality Control OEM (Original Equipment Manufacturer) hoses undergo rigorous testing to ensure that they meet the highest industry standards. This testing includes assessments for flexibility, burst pressure, and hose diameter consistency.

Applications of Four Wire Spiral Hydraulic Hoses

The versatile nature of the OEM four wire spiral hydraulic hose makes it suitable for various applications across different sectors. Some common uses include

1. Construction Equipment Hydraulic hoses are essential in machinery such as excavators, bulldozers, and hydraulic lifts. The four wire spiral design supports the heavy-duty nature of these machines.

oem four wire spiral hydraulic hose

3. Mining Equipment In harsh environments, the durability of four wire spiral hoses ensures that mining equipment operates effectively, even under extreme pressure and stress.

4. Industrial Machinery Factories use hydraulic systems in presses, conveyor systems, and other equipment, making these hoses critical for operational efficiency.

Benefits of Using OEM Four Wire Spiral Hydraulic Hoses

The choice of OEM four wire spiral hydraulic hoses comes with a plethora of advantages. Some of these include

1. High Pressure Resistance Their ability to withstand high pressure minimizes the risk of leaks and failures, which can lead to costly downtime.

2. Enhanced Durability The multi-layer design helps resist abrasions and environmental factors, which contributes to a longer service life compared to standard hoses.

3. Flexibility Despite their strength, four wire spiral hydraulic hoses maintain a level of flexibility that allows for easier installation and routing within complex systems.

4. Safety The robust construction offers improved safety by reducing the incidence of hose bursts and the associated risks in a working environment.

5. Versatile Compatibility These hoses can be tailored to work with various fluids, making them adaptable to multiple hydraulic systems across different applications.

Conclusion

In conclusion, OEM four wire spiral hydraulic hoses play a vital role in ensuring the efficiency and reliability of hydraulic systems across diverse industries. Their sturdy construction, high-pressure capabilities, and versatility make them an excellent choice for challenging applications. When selecting hydraulic hoses, investing in OEM quality guarantees performance, safety, and longevity, ultimately contributing to the success and reliability of industrial and mobile equipment. By understanding the benefits and applications of these hoses, businesses can make informed decisions that enhance operational efficiency and reduce downtime.

-

Reliable PTFE Hose Distribution | Flexible & High-Performance Solutions

NewsAug.27,2025

-

Distribution PTFE Hose: Flexible, Chemical-Resistant Solutions

NewsAug.26,2025

-

SAE 100 R1AT Hydraulic Hose: Smooth, Wrapped & Colourful

NewsAug.25,2025

-

Premium Distribution PTFE Hose | Flexible & Stainless Braided

NewsAug.23,2025

-

Premium Distribution PTFE Hose: Flexible & Durable Solutions

NewsAug.22,2025

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025