335345435

Aug . 26, 2025 00:20 Back to list

Distribution PTFE Hose: Flexible, Chemical-Resistant Solutions

Strategic Considerations for Distribution of PTFE Hoses

In the demanding landscape of industrial fluid conveyance, the integrity and performance of hose systems are paramount. Polytetrafluoroethylene (PTFE) hoses have emerged as a superior solution, offering unparalleled chemical resistance, thermal stability, and durability. This article delves into the critical aspects surrounding the distribution ptfe hose, covering everything from manufacturing intricacies to application advantages and market dynamics, specifically tailored for B2B decision-makers and technical engineers.

The demand for high-performance fluid transfer solutions continues to rise across diverse sectors, driven by stringent safety regulations, the need for enhanced operational efficiency, and the handling of increasingly aggressive media. PTFE's unique properties—including its ultra-low friction coefficient, non-stick surface, and broad operating temperature range from -70°C to +260°C—make it an ideal material for critical applications where conventional rubber or plastic hoses fall short. Understanding the technical specifications, production processes, and market availability of these advanced hoses is crucial for optimizing procurement and ensuring long-term system reliability.

Current Industry Trends and Market Dynamics

The global market for flexible PTFE hose is experiencing robust growth, fueled by expansion in the chemical processing, pharmaceutical, automotive, and food & beverage industries. Key trends include:

- Increasing Demand for High-Purity Solutions: Sectors like pharmaceuticals and semiconductor manufacturing require hoses that do not leach contaminants, making PTFE's inertness invaluable. This drives the market for advanced production ptfe hose with enhanced surface finishes.

- Emphasis on Enhanced Safety and Compliance: Stricter environmental and safety regulations are pushing industries towards more reliable and leak-proof fluid transfer systems. PTFE's chemical resistance and durability minimize failure risks.

- Growth in Specialized Applications: The need for static-dissipative (carbon-lined) PTFE hoses for flammable fluids, or convoluted PTFE hoses for extreme flexibility in robotic applications, is expanding.

- Technological Advancements in Braiding and Jacketing: Innovations in reinforcement materials, such as high-tensile synthetic fibers or multi-layered stainless steel braids, are extending pressure ratings and service life for ptfe hydraulic hose and similar high-pressure applications.

- Customization and Solution-Oriented Offerings: Manufacturers are increasingly providing tailored solutions for specific client needs, including custom bore sizes, lengths, and end-fitting configurations.

The market size for ptfe teflon hose is projected to reach approximately USD 1.2 billion by 2028, growing at a CAGR of around 5-6% from 2023. This growth underscores the increasing reliance on high-performance materials in critical industrial infrastructure.

Detailed Manufacturing Process of distribution ptfe hose

The production of high-quality PTFE hoses is a meticulous process, combining advanced material science with precision engineering. Understanding these steps is vital for assessing product quality and performance.

1. Material Selection & Preparation

High-grade PTFE resin (typically virgin or conductive carbon-filled) is chosen based on application requirements. Reinforcement materials such as 304/316 stainless steel wire for ptfe stainless braided hose or high-strength synthetic fibers (e.g., polyester, aramid) for products like the R8 High Pressure Synthetic Fibre Braid Resin hose are prepared. End-fitting materials (e.g., stainless steel, brass) are also selected.

2. PTFE Tube Extrusion

The PTFE resin is either ram-extruded (for larger, thicker walls) or paste-extruded (for thinner, more flexible tubes). This process forms the seamless, non-porous inner liner. Precise temperature and pressure control are critical to ensure a uniform wall thickness and defect-free internal surface, which directly impacts the hose's chemical resistance and flow characteristics.

3. Braiding/Reinforcement

The extruded PTFE tube is then reinforced. For high-pressure applications, a layer of braided wire (e.g., ptfe steel-braided hose) or synthetic fiber is applied over the inner tube. This braiding provides the structural integrity to withstand high operating pressures and external forces. Multiple layers of braiding can be applied for extremely high-pressure ratings, meeting standards like SAE J517 100R8.

4. Outer Jacket Application (Optional)

Depending on the application, an outer protective jacket (e.g., PVC, EPDM, silicone) may be extruded over the braid. This jacket offers additional abrasion resistance, UV protection, and can be color-coded for identification. For the R8 High Pressure Synthetic Fibre Braid Resin hose, a robust resin jacket provides excellent chemical and abrasion resistance.

5. Curing/Sintering

After extrusion and braiding, the PTFE hose undergoes a sintering process where it is heated to high temperatures (above its crystalline melting point, typically 327°C) and then cooled. This process enhances the material's mechanical properties, making the PTFE denser, stronger, and more dimensionally stable. This step is critical for ensuring the longevity and performance of the ptfe flexible hose pipe.

6. Testing & Quality Control

Each hose undergoes rigorous testing. This includes hydrostatic pressure testing (to burst pressure), electrical conductivity checks (for static-dissipative types), dimensional verification, visual inspection for defects, and flexibility tests. Hoses must adhere to international standards such as ISO 9001, SAE J517, ASTM, and potentially FDA for food-grade applications, ensuring a consistent service life and reliability. The service life of a well-maintained PTFE hose can exceed that of traditional rubber hoses by a factor of 3-5 times in aggressive environments.

Target industries benefiting from such precise manufacturing include petrochemicals, where corrosion resistance is paramount; metallurgy, for handling high-temperature coolants; and water supply & drainage in industrial settings, where chemical purity and long service life reduce maintenance. Advantages in typical application scenarios include significant energy saving due to lower friction coefficients and superior corrosion resistance, reducing equipment wear and chemical degradation.

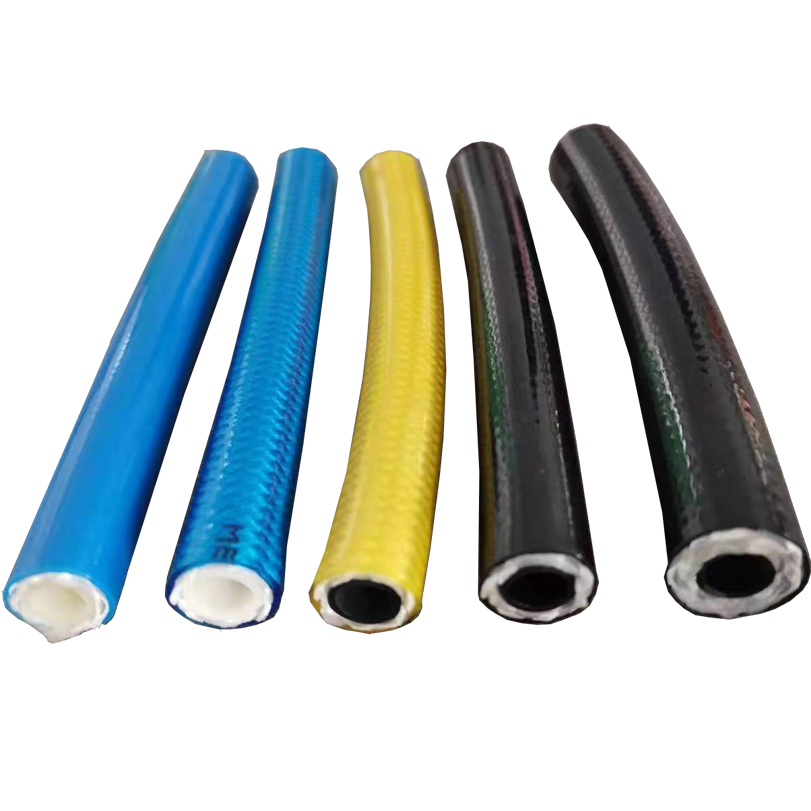

Visual representation of a reinforced PTFE hose for industrial applications.

Technical Specifications and Performance Metrics

The performance of flexible ptfe hose is defined by its core technical specifications. These parameters are crucial for engineers designing fluid transfer systems and for procurement professionals evaluating suitable products.

Key Characteristics of PTFE Hoses:

- Chemical Inertness: Resistant to nearly all industrial chemicals, acids, and bases.

- Temperature Range: Typically -70°C to +260°C (-100°F to +500°F), far exceeding rubber or most thermoplastic hoses.

- Low Friction Coefficient: Facilitates high flow rates and reduces pressure drop.

- Non-Stick Surface: Prevents residue buildup, ideal for high-purity or viscous media.

- Flexibility: The ptfe flex hose offers excellent flexibility, especially convoluted designs, easing installation in confined spaces.

- Non-Aging Properties: Does not deteriorate with exposure to UV, ozone, or weather.

- Sterilizability: Can be steam cleaned or autoclaved, critical for food and pharma.

Product Specification Table: R8 High Pressure Synthetic Fibre Braid Resin Hose

The R8 High Pressure Synthetic Fibre Braid Resin hose, a prime example of advanced distribution ptfe hose technology, offers exceptional performance. Its construction aligns with the SAE J517 100R8 standard for high-pressure thermoplastic hydraulic hoses, modified with a PTFE core for superior chemical resistance.

| Parameter | Value/Description |

|---|---|

| Inner Tube Material | Smooth Bore Extruded PTFE |

| Reinforcement | High Tensile Synthetic Fibre Braid (Single or Double Layer) |

| Outer Cover | Abrasion & Weather Resistant Resin |

| Operating Temperature Range | -50°C to +130°C (-58°F to +266°F) (for R8 standard) (PTFE core up to +260°C) |

| Inner Diameter Range (ID) | DN05 (3/16") to DN25 (1") (typical) |

| Working Pressure (WP) | Up to 4500 PSI (310 Bar) for smaller IDs (e.g., DN06) |

| Burst Pressure (BP) | Typically 4x Working Pressure (e.g., 18000 PSI / 1240 Bar for DN06) |

| Minimum Bend Radius | Varies by ID, from 50mm to 200mm (optimized for flexibility) |

| Standards Compliance | SAE J517 100R8 performance, ISO 9001 certified manufacturing |

Application Scenarios for PTFE Hoses

The versatility and superior performance of ptfe flexible hose pipe enable their widespread adoption across a multitude of industrial applications.

- Chemical Processing: Transfer of aggressive chemicals, solvents, acids, and bases where corrosion resistance is non-negotiable. Examples include loading/unloading chemical tankers, process lines in manufacturing plants, and sampling systems.

- Pharmaceutical & Biotechnology: Conveyance of high-purity pharmaceutical ingredients, sterile fluids, and solvents. The non-leaching, non-stick, and sterilizable properties of ptfe teflon hose are essential here, often requiring FDA-approved materials.

- Food & Beverage: Transfer of edible oils, dairy products, alcoholic beverages, and other food-grade liquids. PTFE hoses prevent flavor contamination and can withstand frequent Clean-in-Place (CIP) and Sterilize-in-Place (SIP) cycles.

- Automotive & Motorsports: High-performance brake lines, fuel lines, and power steering hoses due to their ability to handle extreme temperatures, high pressures, and aggressive fluids like racing fuels and synthetic oils. This is a common application for ptfe hydraulic hose.

- Hydraulics & Pneumatics: High-pressure hydraulic systems in heavy machinery, construction equipment, and industrial robotics where traditional rubber hoses might degrade under chemical exposure or extreme temperatures.

- Adhesive & Paint Transfer: The non-stick surface of PTFE prevents clogging and buildup, crucial for systems transferring glues, resins, and paints.

In each of these scenarios, the inherent advantages of distribution ptfe hose translate into reduced downtime, lower maintenance costs, enhanced safety, and improved product purity.

Technical Advantages Over Conventional Hoses

The decision to invest in flexible ptfe hose is often driven by its distinct technical advantages over traditional rubber, PVC, or other plastic hoses.

- Superior Chemical Resistance: PTFE resists almost all chemicals, unlike rubber which can swell, degrade, or leach when exposed to aggressive media. This extends hose life and prevents contamination.

- Broader Temperature Range: PTFE hoses maintain integrity and flexibility across an extreme temperature spectrum, allowing them to perform reliably in environments from cryogenic to high-heat, where other materials would embrittle or soften.

- Excellent Flex-Fatigue Life: While some PTFE hoses are less flexible than rubber, their resistance to flex-fatigue is significantly higher, meaning they can withstand repeated bending and vibration without material breakdown, especially relevant for ptfe flex hose designs.

- Lower Permeability: PTFE has extremely low permeability to gases and vapors, minimizing effusion and odor transmission, critical for sensitive or hazardous media.

- Cleaner Operation: The non-stick, smooth bore of PTFE prevents particle entrapment and bacterial growth, simplifying cleaning and sterilization processes. This results in purer products and reduced cleaning validation efforts.

- Longer Service Life: Due to their resistance to chemical attack, temperature extremes, and environmental degradation, PTFE hoses generally offer a much longer operational lifespan, reducing replacement frequency and total cost of ownership.

Vendor Comparison and Selection Criteria

Selecting the right vendor for distribution ptfe hose is a strategic decision that impacts operational reliability and cost-efficiency. Key criteria for evaluation include:

- Quality & Certifications: Look for manufacturers with ISO 9001 certification, specific product approvals (e.g., FDA for food contact, SAE J517 for hydraulic applications), and robust quality control procedures.

- Material Traceability: Ensure raw material sourcing is transparent and traceable, especially for critical applications.

- Technical Expertise & Support: A vendor with deep technical knowledge can offer invaluable guidance on hose selection, system design, and troubleshooting.

- Customization Capabilities: The ability to provide bespoke solutions (e.g., specific lengths, fittings, jacket materials, conductive liners) is crucial for specialized requirements.

- Lead Times & Fulfillment: Consistent and reliable delivery schedules are essential for project planning and operational continuity.

- Pricing & Value: While price is a factor, prioritize the total cost of ownership (TCO), considering the hose's lifespan, maintenance, and potential for downtime.

PTFE Hose Reinforcement Comparison

The choice of reinforcement greatly impacts hose performance, with ptfe stainless braided hose and synthetic fiber braids offering distinct advantages.

| Feature | Stainless Steel Braid (e.g., 304/316 SS) | Synthetic Fibre Braid (e.g., R8 Resin Hose) |

|---|---|---|

| Pressure Rating | Very High (up to 6000 PSI+) | High (up to 4500 PSI, as per R8 standard) |

| Flexibility | Moderate, can be stiff at larger IDs | Excellent, often more flexible than SS braid |

| Weight | Heavier | Lighter |

| Corrosion Resistance (External) | Good (316 SS better than 304 SS) | Excellent (resin cover protects fiber) |

| Abrasion Resistance | Good, can fray or wear over time | Excellent, robust resin jacket is highly durable |

| Cost | Typically Higher | Generally More Cost-Effective |

Customized Solutions for Specialized Applications

While standard PTFE hoses meet many needs, specialized industrial requirements often necessitate customized solutions. Reputable manufacturers of production ptfe hose offer a range of customization options to perfectly match application demands.

- Custom Bore Sizes & Lengths: Beyond standard dimensions, hoses can be manufactured to specific internal diameters and precise lengths to optimize flow and fit unique system layouts.

- End-Fitting Configurations: A vast array of end-fittings (e.g., NPT, BSP, JIC, flange, camlock, custom designs) in various materials (stainless steel, brass, carbon steel) can be crimped or swaged onto the hose.

- Jacket Materials: While the R8 High Pressure Synthetic Fibre Braid Resin hose features a robust resin jacket, other options like silicone, PVC, or fire-retardant covers can be applied for specific environmental protection.

- Conductive Liners: For applications involving flammable fluids or where static discharge is a concern, PTFE hoses with an inner carbon-impregnated (conductive) liner are available to safely dissipate static electricity.

- Convoluted vs. Smooth Bore: While smooth bore is common for maximum flow, convoluted teflon ptfe hose offers superior flexibility for dynamic applications or tight bend radii.

- Hose Assemblies: Many vendors provide pre-assembled hoses with crimped fittings, pressure tested, and ready for immediate installation, reducing on-site labor and ensuring quality.

Partnering with a manufacturer capable of these customizations ensures that the fluid transfer system is precisely engineered for optimal performance and safety, eliminating compromises often associated with off-the-shelf solutions.

Real-World Application Case Studies

Case Study 1: Chemical Transfer in a Petrochemical Plant

A major petrochemical facility was experiencing frequent failures of rubber hoses used for transferring concentrated sulfuric acid, leading to hazardous leaks and costly downtime. The rubber hoses degraded within months, requiring constant replacement. Solution: The plant switched to a ptfe stainless braided hose with a smooth bore PTFE liner and 316 stainless steel overbraid. The chemical inertness of the PTFE resisted the sulfuric acid completely, while the stainless steel provided the necessary pressure containment and abrasion resistance. Result: Hose lifespan increased from 3 months to over 3 years, significantly reducing maintenance costs, improving safety records, and enhancing operational uptime. The project achieved a return on investment within 8 months.

Case Study 2: High-Pressure Hydraulic System for Heavy Machinery

A manufacturer of large hydraulic presses faced challenges with traditional rubber hydraulic hoses failing prematurely due to high operating temperatures (up to 120°C) and constant flexing, causing minor but frequent hydraulic fluid leaks. Solution: They implemented the R8 High Pressure Synthetic Fibre Braid Resin hose, specifically chosen for its high-temperature resistance and excellent flex-fatigue properties. The synthetic fiber braid offered a lighter-weight solution with comparable pressure ratings to steel-braided options, while its resin cover provided superior external abrasion resistance. Result: Hose service life more than doubled compared to conventional hoses, drastically reducing hydraulic fluid leakage and associated environmental risks. The improved reliability led to a 15% reduction in unplanned maintenance events.

A closer look at the robust construction of a PTFE hose assembly.

Ensuring Trustworthiness: FAQs, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQs)

- Q: What is the maximum temperature a PTFE hose can withstand?

A: Standard PTFE hoses can operate continuously from -70°C to +260°C (-100°F to +500°F). The specific outer jacket or reinforcement may slightly modify the upper limit for continuous service. - Q: Are PTFE hoses suitable for steam applications?

A: Yes, PTFE hoses are highly resistant to steam and can be used for steam transfer and sterilization cycles (e.g., CIP/SIP) due to their high-temperature rating and non-aging properties. - Q: How do I prevent static discharge when transferring flammable fluids with PTFE hoses?

A: For such applications, it is essential to use conductive (carbon-lined) PTFE hoses. These hoses safely dissipate static electricity to prevent ignition of flammable materials. - Q: Can PTFE hoses be repaired?

A: Typically, industrial PTFE hose assemblies are designed as single, non-repairable units. If a hose is damaged, the entire assembly should be replaced to ensure safety and performance.

Lead Time & Fulfillment

Standard distribution ptfe hose products typically have a lead time of 2-4 weeks, depending on order volume and specific configurations. Custom hose assemblies or large-volume orders may require 4-8 weeks. We maintain a strategic inventory of common hose types and fittings to support urgent requirements and can offer expedited production for critical projects on a case-by-case basis. Our efficient logistics network ensures timely and secure delivery globally.

Warranty Commitments

All our PTFE hose products, including the R8 High Pressure Synthetic Fibre Braid Resin hose, come with a standard 12-month warranty from the date of purchase, covering manufacturing defects and material failures under normal operating conditions. This commitment reflects our confidence in the quality and durability of our ptfe teflon hose offerings. Extended warranty options may be available for specific long-term projects or partnerships.

Customer Support & Technical Assistance

Our dedicated team of technical experts and customer service representatives is available to provide comprehensive support throughout the product lifecycle. From initial consultation and hose selection guidance to installation best practices and troubleshooting, we ensure that our clients receive prompt and knowledgeable assistance. We offer detailed product documentation, application guidelines, and are committed to fostering long-term partnerships built on trust and reliable service.

Conclusion

The strategic selection and effective distribution ptfe hose are pivotal for maintaining operational excellence and safety in demanding industrial environments. With their unmatched chemical, thermal, and mechanical properties, PTFE hoses represent a superior investment compared to conventional alternatives. By understanding the intricate manufacturing processes, leveraging detailed technical specifications, and partnering with knowledgeable vendors offering customized solutions and robust support, businesses can significantly enhance their fluid transfer systems, leading to reduced downtime, lower maintenance costs, and improved overall productivity.

References

- ASTM D3308-16, Standard Specification for Polytetrafluoroethylene (PTFE) Resin Molding and Extrusion Materials. ASTM International.

- SAE J517_201704, Hydraulic Hose. SAE International.

- ISO 9001:2015, Quality management systems – Requirements. International Organization for Standardization.

- "The Chemistry and Physics of PTFE." Fluorine Chemistry Reviews, vol. 1, 1967, pp. 247-290.

- "Global PTFE Hose Market Trends and Forecasts," Market Research Report, 2023.

This is the last article

-

Distribution PTFE Hose: Flexible, Chemical-Resistant Solutions

NewsAug.26,2025

-

SAE 100 R1AT Hydraulic Hose: Smooth, Wrapped & Colourful

NewsAug.25,2025

-

Premium Distribution PTFE Hose | Flexible & Stainless Braided

NewsAug.23,2025

-

Premium Distribution PTFE Hose: Flexible & Durable Solutions

NewsAug.22,2025

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025