335345435

Jul . 31, 2025 15:40 Back to list

Industrial Distribution PTFE Hose - High Purity & Flexibility

Distribution PTFE hose and its related products (flexible PTFE hose, PTFE flex hose, PTFE flexible hose pipe, PTFE hydraulic hose, PTFE stainless braided hose, PTFE steel-braided hose, PTFE Teflon hose, Teflon PTFE hose) are critical components in modern industrial fluid transfer. As fluid transfer challenges become increasingly demanding, particularly in petrochemical, metallurgy, food & pharma, and hydraulic systems, specifications and performance standards are more crucial than ever.

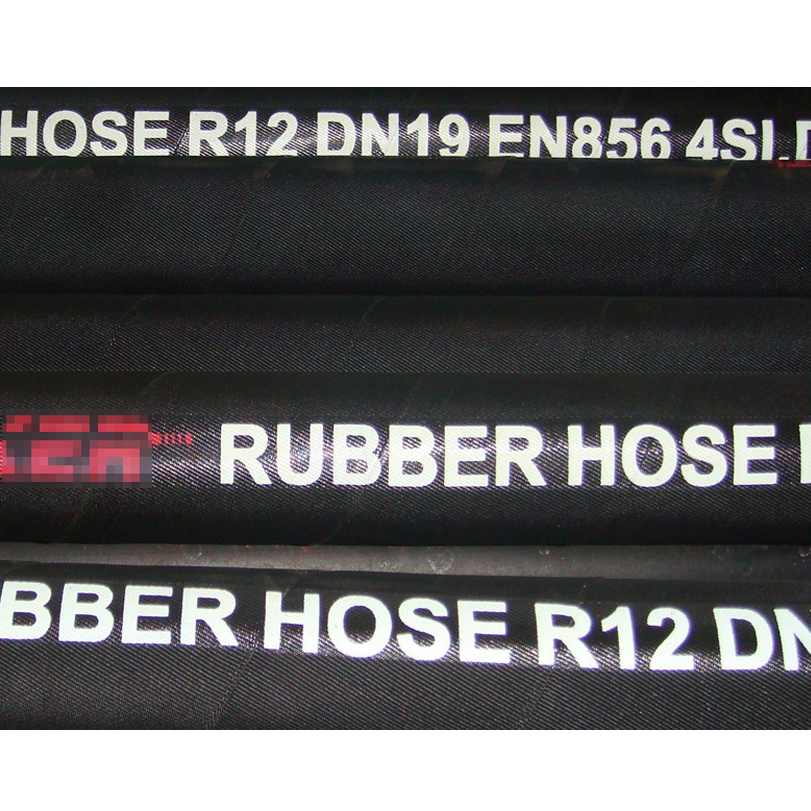

SAE100R12 Best Price High Pressure Hydraulic Hose (Product Details) is a leading solution in this segment, merging advanced material science with robust construction and strict compliance to ISO/ANSI standards.

Industry Trends and Growth: The Rise of Distribution PTFE HoseThe global distribution PTFE hose market is projected to reach $1.32 billion by 2028 (CAGR: 6.4%, MarketsandMarkets, 2023). Drivers include:

- Stringent regulatory standards (ISO 14001, FDA, SAE J517)

- Rising demand in cleanroom, chemical, pharmaceutical, and food sectors — all requiring superior chemical, thermal, and pressure resistance

- Adoption of automation and precision in hydraulic and pneumatic control lines

| Type | Inner Diameter (mm) | Working Pressure (MPa) | Burst Pressure (MPa) | Min. Bending Radius (mm) | Temperature Range (°C) | Reinforcement | Certifications |

|---|---|---|---|---|---|---|---|

| Flexible PTFE Hose | 4.8–25.4 | 6.9–28 | 15–80 | 55–320 | -70 ~ +260 | 304/316 SS Braided | ISO 9001, FDA |

| PTFE Hydraulic Hose | 6.4–51.0 | 13–35 | 40–120 | 80–420 | -54 ~ +220 | High-tensile steel wire | SAE J517, ISO 18752 |

| PTFE Stainless Braided Hose | 3.2–19.1 | 9–23 | 28–70 | 60–200 | -70 ~ +260 | SS304 Double Braided | FDA, ISO 14001 |

| PTFE Teflon Hose | 2.8–25.0 | 8–21 | 16–54 | 50–180 | -73 ~ +260 | SS304/SS316/Wire Braiding | RoHS, ISO, FDA |

| SAE100R12 Hydraulic Hose | 12.0–38.0 | 27.6–41.4 | 110–170 | 240–600 | -40 ~ +100 | 4-Spiral Steel Wire | SAE, EN, ISO |

Preparation

Precision & QA

(ISO/ANSI/FDA)

-

Material: 100% Virgin PTFE (Polytetrafluoroethylene), SS304/SS316 Reinforcement

Benefits: Highest chemical, thermal, and corrosion resistance; non-reactive, low friction coefficient (~0.09), FDA compliant. - Manufacturing: Multistage extrusion, sintering, CNC machining for dimensional stability within ±0.1mm and consistent wall thickness, spiral steel-wire or stainless-steel outer braiding, custom length/diameter on request.

- Testing & Standards: 100% Hydrostatic Test (x2 Working Pressure), Leakage Helium mass spectrometry (

- Service Life: 10–15 years (industrial settings), 5x longer than typical rubber/nylon hoses.

- Industry Coverage: Oil & gas, chemical transport, food & beverage, auto, semiconductor, water supply/filtration, power, and pharmaceutical manufacturing.

- Petrochemical & Chemical Plants: Leak-free acid/base/solvent transfer, outperforming rubber in anti-permeation, allowing system integrity in refineries. Case: Middle East PetroCo cut annual hose replacements from 35% (rubber) to <7% after switching to PTFE flex hose with ISO 14001 certification.

- Food & Pharma: FDA-grade liner ensures zero contamination, ultra-cleaning capability (CIP/SIP), passing EU/FDA tests for extractables/leachables.

- Hydraulics & Auto Manufacturing: Handles repeated 27–41MPa surges and vibration; spiral steel-braided hoses retain flexibility with >1 million flex cycles (ISO 6802 test).

- Water Supply/Drainage: Extreme corrosion resistance allows 15-year duty in aggressive municipal and deionized water environments.

- Pharma/Biotech: Ultra-low protein binding, pH inertness enables use in vaccine fill/finish, chromatography, and high-purity water transfer.

A European pharmaceutical company implemented distribution PTFE hose assemblies in their CE-marked fill/finish line, achieving a 98.7% reduction in batch contamination alerts, with 100% pass rate in post-sterilization leak and leach tests per EN 16643:2016.

- Ultra-wide Chemical Compatibility: Suitable for virtually all known chemicals; unaffected by acids, alcalis, or solvents (see DuPont PTFE chemical compatibility).

- Non-ageing, UV/Ozone Stable: Maintains properties for decades, zero-crack evidence (Arrhenius aging tested).

- Superb Flex-Fatigue Performance: >1 million flex cycles @ working pressure (ISO 6802 laboratory test data).

- Thermal Resistance: Can operate under extreme cold (-73°C) or heat (+260°C) without plastomeric deformation.

- Zero Toxicity, Non-leaching: FDA/EU1935-approved; safe for pharmaceutical or food contact.

- Minimized Pressure Drop: Inner surface roughness Ra<0.2μm (micro-finished), enabling higher flow rates.

- Custom Fit: CNC precision-cut lengths, crimped or swaged ends per customer spec (ISO/ANSI/EN thread standards supported).

| Brand/Supplier | Main Product | Pressure Range (MPa) | Certifications | Lead Time (Days) | Custom OEM/ODM |

|---|---|---|---|---|---|

| Daiyi Rubber Hose | SAE100R12 Best Price High Pressure Hydraulic Hose | 27–41 | ISO, EN, SAE | 7–15 | Yes |

| Parker Hannifin | Parker 944B/955B/Polyflex | 8–28 | ISO, FDA, SAE | 21–30 | Yes |

| Eaton Aeroquip | Eaton Everflex, Polytetra® | 7–23 | SAE, ISO | 20–30 | On Request |

| Swagelok | PTFE Core SS-Braided | 6–30 | ISO, FDA, USP VI | 15–25 | Yes |

| Hose Master | Annuflex/PTFE | 7–22 | ISO, RoHS | 25–35 | Yes |

- Custom Hose Assembly: Select bore, reinforcement (single/double braided), length, fitting (CNC-milled, ISO/EN/ANSI thread), wrap/label branding.

- Sample & Prototyping: 2–4 days (flush, certify, ship).

- Mass Production: 7–15 days typical, +2 days for non-standard construction/marking.

- Certifications Provided: FDA 21 CFR 177.1550, ISO 9001/14001 Audit Reports, Pressure/Continuity/Material Test Records.

Order confirmation → 100% deposit/payment → Manufacturing (QC at every step) → Full Factory Test (ISO/EN standards) → Secure packaging → Courier/Freight shipment → Installation Guidance & 24/7 Tech Support.

- Comprehensive Warranty: 2 years standard (extendable up to 5 years on premium lines), covers all manufacturing defects, premature aging, fitting leaks.

- Certification & Traceability: All shipments include unique product batch traceable reports and third-party test certification.

- Customer Support: 7×24 email/phone consultation, on-site installation guidance; rapid response for any technical or post-sales issues.

- Replacement Guarantee: 100% free replacement for verified product failure (within the warranty period), including logistics cost for priority clients.

- “The Global PTFE Hose Market: Opportunities and Challenges” – RubberNews.com

- “ISO Standards for Hydraulic Hoses” – ISO 18752:2022

- Hydraulic Hose Forums: Hydraulics & Pneumatics Community

- Case studies and materials science articles in ScienceDirect—PTFE Hose Engineering

- Technical Discussion: “Comparing PTFE and Rubber Hoses, Durability Testing” – EngTips Engineering Forums

-

Premium Chemical Resistant Distribution PTFE Hose

NewsAug.01,2025

-

Industrial Distribution PTFE Hose - High Purity & Flexibility

NewsJul.31,2025

-

Durable Twin Hydraulic Hose for High-Pressure Systems

NewsJul.31,2025

-

Discount Hydraulic Hose Factories – Bulk Supply & Quality Assurance

NewsJul.30,2025

-

Hydraulic Hose Crimping Machine for Precise & Durable Connections

NewsJul.29,2025

-

High Pressure 4SH Hydraulic Hose for Heavy Duty Applications

NewsJul.29,2025