335345435

Th12 . 29, 2024 10:19 Back to list

OEM Manufacturer of Suction and Delivery Hoses for Various Applications and Industries

The Importance of OEM Suction and Delivery Hose Manufacturers

In a rapidly evolving industrial landscape, the role of specialized manufacturers has become increasingly significant. One such critical component within various industries is the suction and delivery hose. Original Equipment Manufacturers (OEMs) specializing in this field play a vital role in ensuring efficiency, safety, and performance across diverse applications.

Understanding Suction and Delivery Hoses

Suction and delivery hoses are essential components in fluid transfer systems. They are designed to transport liquids, slurries, and gases from one location to another. These hoses vary in diameter, length, and material composition, depending on the application requirements. Suction hoses typically create a vacuum to pull liquid, while delivery hoses are responsible for conveying the fluid to its destination. OEM manufacturers produce these hoses to ensure they meet specific industry standards and client specifications.

The Need for OEM Manufacturers

The importance of choosing the right OEM for suction and delivery hoses cannot be overstated. First and foremost, quality is paramount. Hoses that fail can lead to costly downtime, safety hazards, and potential damage to surrounding equipment and environments. OEMs invest in robust quality control processes to ensure their products are reliable and meet or exceed industry regulations.

Moreover, custom design capabilities set OEM manufacturers apart. Every application has unique requirements, and standard hoses may not suffice. Whether it’s for the agricultural sector, manufacturing plants, or construction sites, OEMs can design hoses tailored to specific needs, ensuring optimal performance and longevity of the product.

Materials and Technologies in Hose Manufacturing

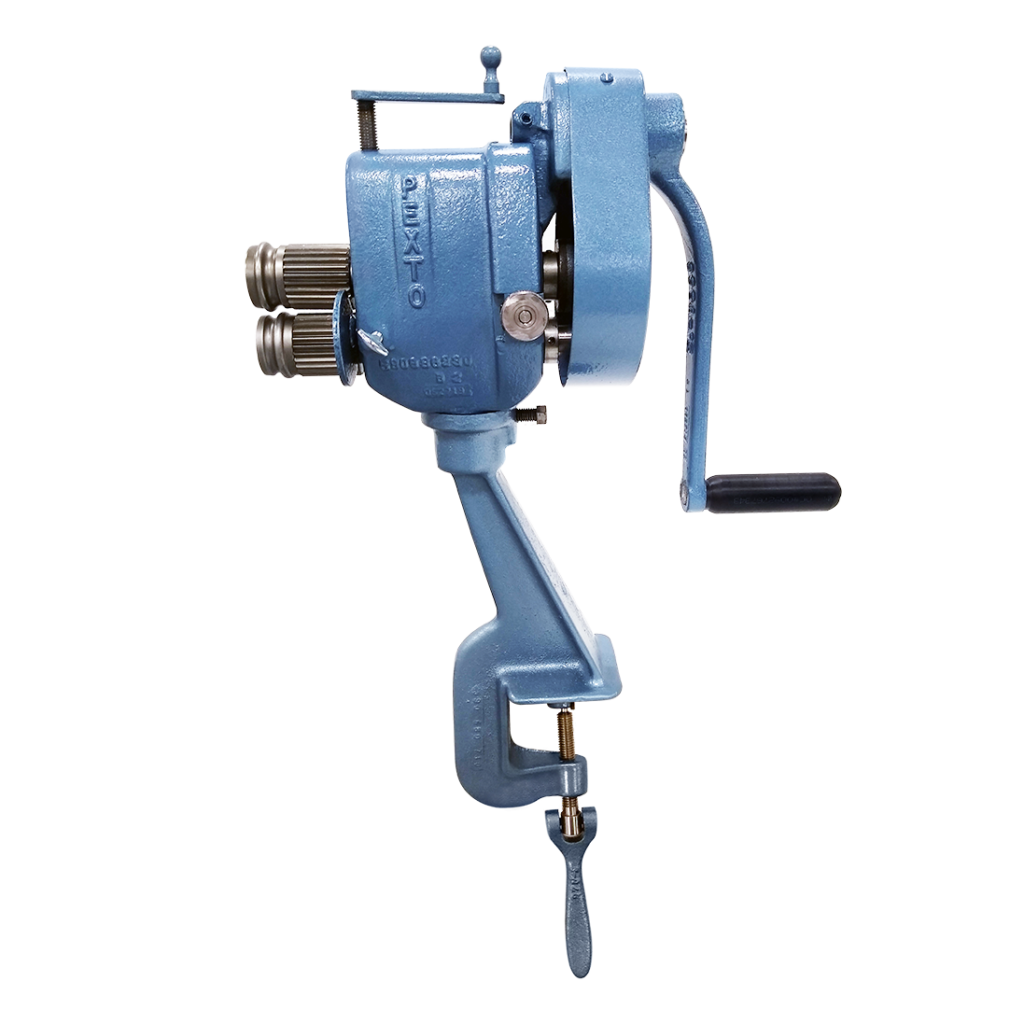

oem suction and delivery hose manufacturer

In the realm of suction and delivery hoses, material choice is critical. OEMs utilize various materials, including rubber, polyurethane, PVC, and metal, depending on the intended application. For instance, hoses used in chemical transfer require resistance to corrosive substances, while those in food service need to be compliant with health regulations. Advanced manufacturing technologies also play a vital role. The use of high-frequency welding, for instance, allows for seamless connections, reducing the possibility of leaks.

Benefits of Working with OEM Manufacturers

When industries partner with reputable OEM manufacturers for their suction and delivery hose needs, they benefit in multiple ways. A significant advantage is the provision of expert knowledge and support. OEMs often employ specialists who understand the intricacies of fluid dynamics and materials science, enabling clients to make informed decisions regarding their hose requirements.

Additionally, OEMs generally offer comprehensive after-sales support, including installation guidance, maintenance tips, and troubleshooting assistance. This ongoing relationship fosters a sense of reliability and confidence in the products, ensuring that customers can trust their hoses to perform under pressure.

Environmental Considerations

In today’s environmentally conscious market, OEM manufacturers are also focusing on sustainability. Many are adopting eco-friendly materials and production methods to minimize their carbon footprint. This commitment not only benefits the environment but also meets the growing demand from consumers and industries for sustainable practices.

Conclusion

The significance of OEM suction and delivery hose manufacturers extends far beyond mere product supply. They are essential partners in ensuring operational efficiency, safety, and compliance across industries. By prioritizing quality, customization, material choice, and sustainability, these manufacturers enable businesses to thrive in an increasingly competitive marketplace. Therefore, when selecting a supplier for suction and delivery hoses, companies should consider working with established OEMs to secure the reliability and performance they need to succeed.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025