335345435

Th11 . 24, 2024 16:39 Back to list

oem din hydraulic hose fittings factories

OEM DIN Hydraulic Hose Fittings A Comprehensive Overview of Factories and Their Importance

In today's industrial landscape, the role of hydraulic systems is crucial across various applications, from construction machinery to agricultural equipment. A key component of these systems is hydraulic hose fittings, which connect hoses and tubes to components, ensuring the efficient transmission of fluid under pressure. Among the various standards for hydraulic fittings, the DIN (Deutsches Institut für Normung) fittings are widely recognized, particularly in Europe. This article delves into the significance of OEM (Original Equipment Manufacturer) DIN hydraulic hose fittings and the importance of the factories producing them.

Understanding DIN Hydraulic Hose Fittings

DIN hydraulic hose fittings are designed according to specific standards set by the Deutsches Institut für Normung. These fittings are known for their reliability and robustness in high-pressure environments. The specifications cover various types of fittings, including metric threads, which are particularly advantageous for European manufacturers. The standardized designs ensure compatibility with different hydraulic systems, facilitating easier replacements and repairs.

The main categories of DIN fittings include the DIN 2353 series, which features both welded and crimped options for attaching hoses to other hydraulic components. These fittings are made from high-quality materials like stainless steel and carbon steel, offering durability, corrosion resistance, and high tensile strength.

The Role of OEM in Hydraulic Fittings Production

OEM manufacturers play a critical role in the production of DIN hydraulic hose fittings. They produce components that are designed to match the specifications of original equipment used in various hydraulic systems. This is essential because the integrity of hydraulic applications relies heavily on the performance and quality of the fittings used.

OEM manufacturers invest significantly in research and development to ensure that their fittings meet or exceed industry standards. Their products are often subjected to rigorous testing, including pressure testing and environmental resistance assessments, to guarantee that they can perform under extreme conditions. This commitment to quality gives customers peace of mind, knowing that the fittings they purchase will not fail under operational stress.

Importance of Factories Producing OEM DIN Hydraulic Hose Fittings

oem din hydraulic hose fittings factories

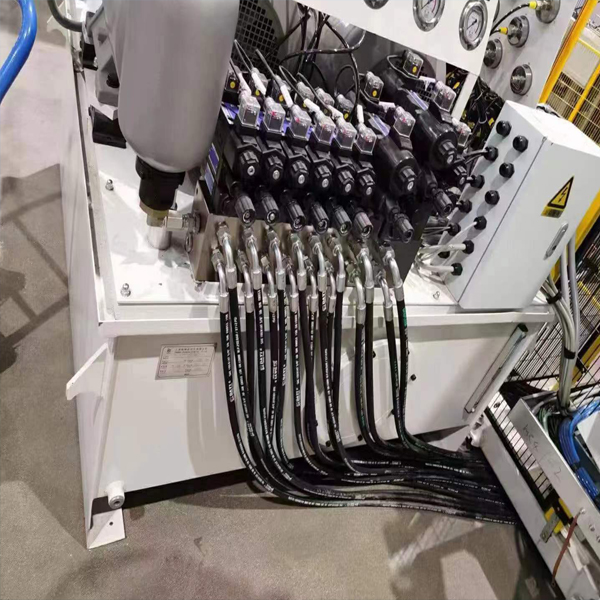

The factories that manufacture OEM DIN hydraulic hose fittings are equipped with advanced technology and skilled labor. These facilities often feature automated production lines that increase efficiency and ensure the precision needed in the machining and assembling of fittings. Automation minimizes human error, leading to higher quality products and decreased waste in the manufacturing process.

Moreover, these factories adopt stringent quality control measures throughout the manufacturing process. From raw material selection to final inspection, each stage is monitored to avoid defects. For instance, materials undergo tests to ensure they meet industry-grade specifications, while the finished products are trialed to ascertain their reliability.

In addition to quality assurance, many factories adhere to environmental regulations and actively seek to minimize their ecological footprint. This is increasingly important as industries operate under greater scrutiny concerning sustainability. Companies that prioritize eco-friendly practices often find themselves favored by customers looking to align with sustainable brands.

The Global Market for OEM DIN Hydraulic Hose Fittings

The demand for OEM DIN hydraulic hose fittings is on the rise, driven by global industrial growth. As various sectors expand, the need for reliable hydraulic systems increases. The automotive, aerospace, and construction industries are particularly significant contributors to this demand.

In response to this demand, factories worldwide are ramping up production capacities. Countries like Germany, Italy, and China are notable leaders in hydraulic fitting manufacturing, offering a variety of products that cater to different market needs. Global sourcing has become a common practice, allowing companies to balance cost-effectiveness with quality.

Conclusion

In conclusion, OEM DIN hydraulic hose fittings are vital components in hydraulic systems, providing reliability and efficiency across various applications. The factories that produce these fittings play a critical role in ensuring that standards are met, quality is maintained, and the needs of diverse industries are satisfied. As the global demand for hydraulic components continues to grow, these manufacturers must remain at the forefront of innovation and quality control to meet the evolving requirements of modern industries. The commitment to excellence in producing DIN fittings not only enhances operational efficiency but also contributes to the overall safety and effectiveness of hydraulic systems worldwide.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025