335345435

Th7 . 20, 2024 10:36 Back to list

High-Quality Flexible High Pressure Rubber Hydraulic Hose Production and Manufacturing Solutions

The Evolution and Production of Flexible High Pressure Rubber Hydraulic Hoses

In the realm of industrial applications, the importance of hydraulic systems cannot be overstated. These systems are integral to the functionality of machinery across a multitude of sectors, including construction, manufacturing, and automotive. At the heart of these hydraulic systems lies a crucial component the flexible high-pressure rubber hydraulic hose. This article explores the significance, manufacturing process, and advancements in these essential industrial components.

Importance of Flexible High Pressure Rubber Hydraulic Hoses

Flexible high-pressure rubber hydraulic hoses are designed to transfer hydraulic power effectively and safely. These hoses are built to withstand intense pressure and adverse environmental conditions, ranging from extreme temperatures to exposure to oils and chemicals. The flexibility of these hoses allows for ease of installation and maneuverability, making them suitable for dynamic applications where movement and positional changes occur frequently.

In various industries, the reliability of hydraulic hoses is critical, as failure can lead to severe operational downtime and safety hazards. Therefore, the demand for high-quality hydraulic hoses has increased significantly, prompting manufacturers to innovate and enhance their products continually.

The Manufacturing Process

The production of flexible high-pressure rubber hydraulic hoses involves several intricate steps to ensure optimal performance and safety. The primary materials used in the manufacturing process are high-quality synthetic rubber, reinforcing layers (such as steel wire), and protective sleeves.

1. Material Selection The first step involves selecting the appropriate rubber compounds that offer resistance to high pressure, abrasion, and environmental factors. Synthetic rubbers like nitrile rubber and neoprene are particularly popular for their resilience and flexibility.

2. Reinforcement To enhance the strength of hydraulic hoses, manufacturers integrate multiple layers of reinforcement. Steel wire braiding or spiraling is commonly used. This reinforcement allows the hose to withstand high pressure, protecting the inner tube from bursting under stress.

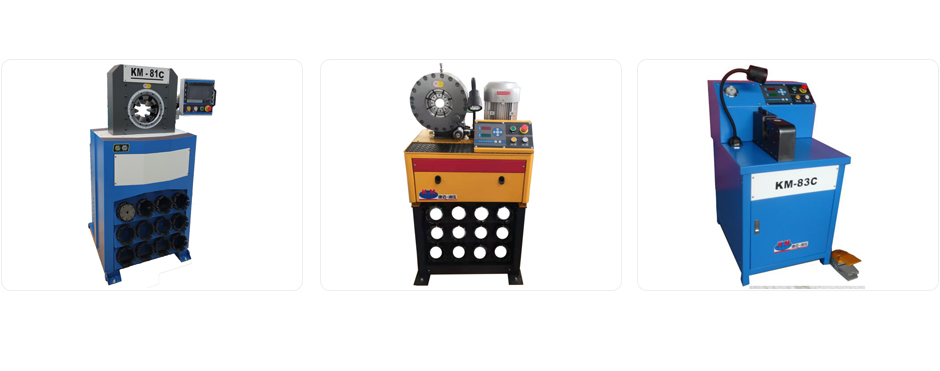

flexible high pressure rubber hydraulic hose factory

3. Extrusion Once the materials are prepared, the rubber is extruded into a tube shape. This process involves heating and shaping the rubber to create the inner and outer layers of the hose.

4. Curing After extrusion, the hose undergoes a curing process known as vulcanization. This step is crucial as it chemically modifies the rubber, enhancing its elasticity, durability, and overall performance. Curing typically involves heating the rubber in an oven to activate the curing agents.

5. Testing Quality control is paramount in the production of hydraulic hoses. Each hose undergoes rigorous testing procedures, including pressure testing, burst testing, and checking for leaks. These tests ensure that the hoses can withstand the operational conditions they will face in the field.

6. Finishing Finally, the hoses are cut to the required lengths, and end fittings are attached, ensuring compatibility with the hydraulic systems they will integrate with.

Innovations in Hydraulic Hoses

The modern era has seen significant advancements in the materials and technologies used for manufacturing flexible high-pressure rubber hydraulic hoses. Innovations such as eco-friendly materials and enhanced manufacturing techniques have improved not only the durability but also the environmental impact of hydraulic hoses.

Moreover, technologies like computer-aided design (CAD) and automation in manufacturing have increased precision, reduced waste, and improved production efficiency. Manufacturers are now able to produce hoses tailored to specific needs, enhancing their adaptability across different industrial settings.

Conclusion

Flexible high-pressure rubber hydraulic hoses are indispensable components within hydraulic systems. As industries continue to evolve and demand greater efficiency, the manufacturing processes and technologies behind these hoses will undoubtedly advance, ensuring they meet the stringent demands of modern applications. With a commitment to quality and innovation, factory operators are poised to support this crucial sector, fostering advancements that will benefit diverse industries around the globe.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025