335345435

Th12 . 10, 2024 23:31 Back to list

Top Manufacturers of CNG Hose for Reliable Fuel Solutions

An Overview of CNG Hose Manufacturers Innovation and Quality in Natural Gas Applications

Compressed Natural Gas (CNG) has emerged as a significant alternative to traditional fossil fuels, offering a cleaner and more sustainable energy source. As the demand for CNG vehicles and fueling infrastructure continues to grow, the necessity for high-quality CNG hoses has become increasingly evident. This article delves into the role of CNG hose manufacturers, the innovations they bring to the table, and the crucial importance of quality in ensuring safety and efficiency in natural gas applications.

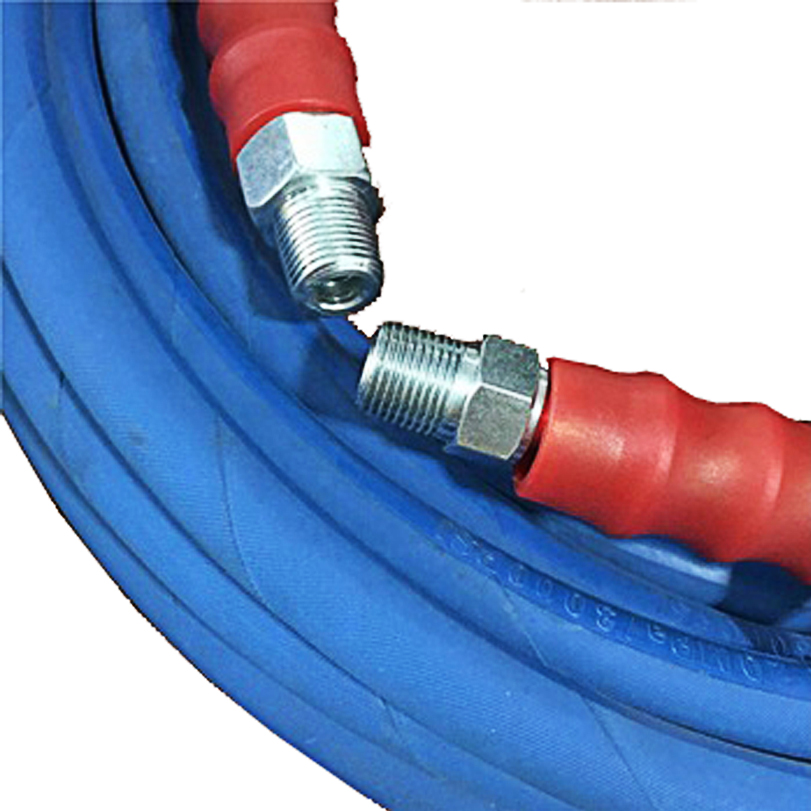

Understanding CNG Hoses

CNG hoses are specialized tubing designed to transport compressed natural gas from one point to another, typically from a storage tank to a vehicle or a dispenser. These hoses are engineered to withstand high pressures and are made from materials that can resist degradation from exposure to natural gas and other environmental factors. The effectiveness of a CNG hose is critical, as it directly impacts the performance of CNG-fueled systems and vehicles.

The Role of CNG Hose Manufacturers

CNG hose manufacturers play a pivotal role in the natural gas supply chain. They are responsible for designing, producing, and testing hoses that meet stringent industry standards. These manufacturers are tasked with creating products that not only ensure efficient gas delivery but also prioritize safety. Failure to meet these standards can result in hazardous situations, including leaks, explosions, and environmental damage.

The process begins with extensive research and development (R&D). Manufacturers invest in advanced technologies and materials to produce hoses that can endure elevated pressures and offer longevity. This R&D is vital, as it allows manufacturers to stay ahead of evolving regulations and customer needs.

Innovations in CNG Hose Manufacturing

Modern CNG hose manufacturers have incorporated various innovative practices into their production processes. For instance, the use of thermoplastic elastomers (TPE) and other high-grade materials allows for greater flexibility and resistance to wear and tear over time. Manufacturers are also adopting multi-layered construction, enhancing the durability and performance of hoses in demanding conditions.

Another breakthrough in CNG hose technology is the integration of smart sensors. These sensors can monitor pressure and detect leakages, providing real-time data to operators. This not only improves safety but also enhances the operational efficiency of CNG systems.

cng hose manufacturers

Additionally, manufacturers are embracing sustainable practices in their operations. This includes using recyclable materials and minimizing waste during production. As environmental concerns rise, these practices not only meet regulatory demands but also resonate with eco-conscious consumers and businesses.

Quality Assurance and Safety Standards

Quality assurance is a cornerstone of CNG hose manufacturing. Reputable manufacturers adhere to international safety standards, such as ISO and SAE guidelines. These standards ensure that hoses can withstand rigorous use and extreme temperatures, which are essential for transportation and storage solutions involving compressed natural gas.

Manufacturers implement comprehensive testing protocols throughout the production process. This includes pressure testing, burst testing, and age testing to evaluate the longevity and performance under different conditions. By prioritizing quality and thorough testing, manufacturers can significantly reduce the risk of failure and protect both users and the environment.

The Future of CNG Hose Manufacturing

With the continuous advancement in technology and materials, the future of CNG hose manufacturing looks promising. As the global push for cleaner energy solutions intensifies, the demand for efficient and reliable CNG systems will only grow. Manufacturers will need to keep innovating, whether through improved materials or enhanced monitoring technologies.

Moreover, collaboration between manufacturers, vehicle makers, and government regulators will play a crucial role in shaping the future of CNG applications. By working together, these stakeholders can ensure that standards evolve and that products meet the ongoing challenges posed by a changing energy landscape.

Conclusion

CNG hose manufacturers are integral to the integrity and safety of natural gas systems. Through a commitment to innovation, quality, and sustainability, these manufacturers are paving the way for a cleaner and more efficient energy future. As the demand for CNG continues to rise, their role will become increasingly vital in ensuring that natural gas remains a reliable and safe energy source for generations to come.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025