335345435

Th11 . 12, 2024 06:17 Back to list

china oil suction and discharge rubber hose factories

The Evolution of Oil Suction and Discharge Rubber Hoses in China

In recent years, the demand for efficient and durable oil suction and discharge rubber hoses has markedly increased, particularly in China, where the industrial sector continues to flourish. These hoses play a crucial role in the transfer of oil and other liquids, and their functionality depends heavily on the materials and manufacturing techniques used.

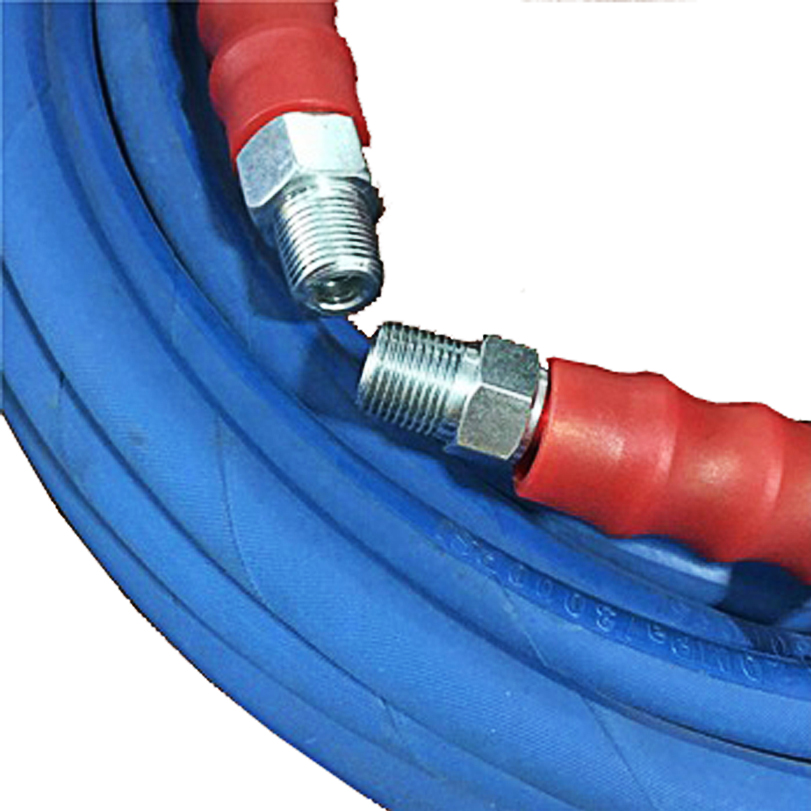

Oil suction and discharge hoses are designed to handle a variety of fluids under different conditions. Typically constructed from rubber, these hoses are reinforced with high-strength materials to withstand the wear and tear associated with hydraulic applications. The quality and reliability of these hoses are vital for industries such as petrochemicals, maritime, and construction, where they are subjected to extreme pressures and various environmental conditions.

Manufacturing Process in China

China is home to numerous factories specializing in the production of oil suction and discharge rubber hoses. These facilities utilize advanced manufacturing technologies to ensure the highest quality products. The production process typically involves several critical steps

1. Material Selection The first step in manufacturing rubber hoses is the selection of high-quality rubber compounds. These materials must exhibit excellent oil resistance, flexibility, and durability. Commonly used rubber types include neoprene, nitrile, and synthetic rubber blends.

2. Extrusion The selected rubber is then extruded into the desired shape and size. This process involves feeding the rubber compound through a machine that shapes it into a continuous hose, which is then cut to appropriate lengths.

3. Reinforcement To enhance the strength and durability of the hoses, different layers of reinforcement materials, such as textile or steel wire, are added during the manufacturing process. This step is crucial for ensuring that the hoses can withstand high pressures during operation.

china oil suction and discharge rubber hose factories

5. Testing Quality control is paramount. Factories conduct rigorous testing to verify that the hoses meet industry standards for pressure capacity, flexibility, and overall performance.

Market Trends and Innovations

As China's industrial landscape evolves, so do the technological advancements in the production of oil suction and discharge hoses. Manufacturers are increasingly integrating modern technologies, such as automated production lines and advanced testing equipment, to enhance efficiency and product quality.

Sustainability also plays a significant role in shaping the future of hose manufacturing. With growing environmental concerns, many factories are exploring eco-friendly materials and production processes to minimize their carbon footprint. Innovations such as biodegradable hoses and recyclable materials are making inroads into the market, catering to environmentally conscious consumers.

The Future of the Industry

Looking ahead, the oil suction and discharge rubber hose industry in China is poised for further growth. The increasing demand for oil and gas, coupled with expanding infrastructure projects, will likely drive the need for reliable transfer solutions.

Furthermore, as international trade continues to increase, Chinese manufacturers have the opportunity to export their products globally. By adhering to international quality standards and certifications, these factories can enhance their reputation and competitiveness on the world stage.

In conclusion, China's oil suction and discharge rubber hose industry is a significant player in the global market. With a focus on quality manufacturing, innovative technologies, and sustainability, these factories are not only meeting current demands but are also setting the stage for future advancements in the industry. As the world becomes more interconnected, the importance of reliable oil transfer solutions cannot be overstated, and China's manufacturers are at the forefront of this critical sector.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025