335345435

Kas . 21, 2024 20:02 Back to list

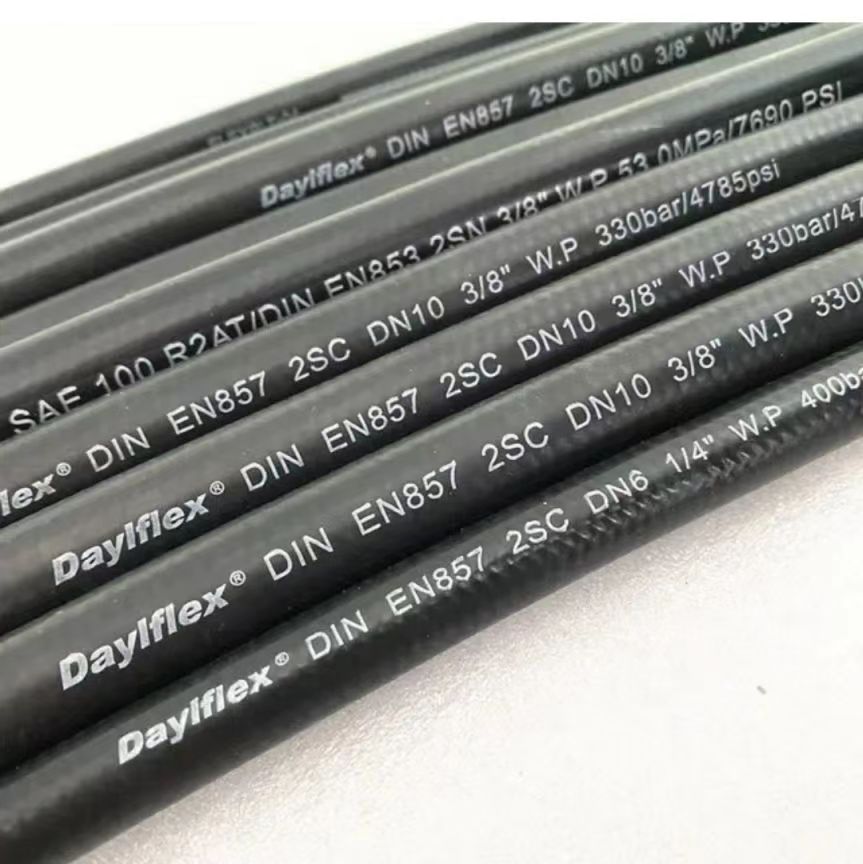

china black air hose factory

The Role of Black Air Hose Factories in China

In the modern manufacturing landscape, the demand for high-quality industrial components is ever-increasing. Among these crucial components, black air hoses play a significant role in various applications ranging from construction to automotive and manufacturing industries. Within this bustling market, China has emerged as a global leader in the production of black air hoses. This article delves into the significance of black air hose factories in China, examining their capabilities, innovations, and impact on the global market.

Understanding Black Air Hoses

Black air hoses are essential components used to transport compressed air for various applications. These hoses must be durable, flexible, and resistant to abrasions and environmental conditions. Their construction typically involves synthetic rubber or PVC, designed to withstand high pressure while ensuring maximum airflow. The versatility of black air hoses makes them suitable for a range of equipment, including pneumatic tools, air compressors, and spray guns.

The Chinese Manufacturing Advantage

China's black air hose factories have positioned themselves as competitive players in the global market due to several factors. Firstly, the country's robust manufacturing infrastructure enables large-scale production, which leads to economies of scale. This allows Chinese manufacturers to keep costs down while maintaining high-quality standards. Additionally, advancements in manufacturing technology have enabled factories to enhance efficiency and reduce waste, resulting in environmentally friendly production processes.

Another significant advantage lies in China’s comprehensive supply chain. With access to vast quantities of raw materials and components, manufacturers can quickly respond to market demands. This agility is vital for meeting the fluctuating needs of domestic and international clients, ensuring that black air hoses can be produced and delivered promptly.

Innovations in Production

china black air hose factory

Innovation is at the heart of the success of China's black air hose factories. Many manufacturers are investing in research and development to improve the performance and durability of their products. For instance, some factories have begun incorporating advanced materials that provide greater resistance to wear and tear, leading to an extended lifespan of the hoses. Additionally, innovations in manufacturing techniques, such as utilizing automated production lines, have enhanced consistency and quality control.

Furthermore, factories are increasingly focusing on customization, allowing customers to specify certain dimensions, colors, and features tailored to their specific applications. This personalized approach not only meets client needs but also fosters long-term business relationships.

Export and Global Reach

As a hub for black air hose production, China has established a robust export infrastructure. Many factories are equipped to handle international shipping logistics, ensuring that products reach global markets efficiently. The quality of Chinese-made black air hoses has garnered recognition worldwide, with many businesses relying on them as essential components in their operations.

The global demand for high-quality black air hoses continues to grow, driven by expanding industries such as construction, automotive, and manufacturing. Consequently, China's position as a leading supplier is likely to strengthen as factories continue to innovate and adapt to market trends.

Conclusion

China’s black air hose factories are not just manufacturers; they are critical players in the global industrial supply chain. Their ability to produce high-quality, durable products at competitive prices, combined with ongoing innovations and a commitment to customer satisfaction, positions them favorably in the marketplace. As industries worldwide continue to expand, the importance of reliable suppliers like China’s black air hose manufacturers will remain paramount, ensuring that the flow of productivity continues unhindered. In an era where efficiency, quality, and adaptability are crucial, these factories are poised to play a vital role in shaping the future of industrial manufacturing.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025