335345435

Eki . 17, 2024 08:07 Back to list

Quarter Inch 2038 Air Hose Manufacturer and Supply Solutions for Your Needs

Exploring the Air Hose Manufacturing Industry

In today's dynamic industrial landscape, the demand for efficient and reliable pneumatic systems has surged. A crucial component of these systems is the air hose, which plays a pivotal role in ensuring the seamless transfer of compressed air across various applications. This article delves into the manufacturing of air hoses, highlighting the intricacies of the industry, particularly focusing on the processes involved, quality control measures, and the future of air hose manufacturing.

The Air Hose Manufacturing Process

At the heart of air hose production lies a meticulous manufacturing process, combining technology and skilled craftsmanship. The journey begins with selecting high-quality raw materials, typically synthetic rubber or thermoplastic, known for their durability, flexibility, and resistance to wear and tear. The choice of material significantly influences the performance of the hose, determining how well it can withstand pressure and environmental conditions.

Once the materials are procured, the manufacturing process commences. It typically involves several key stages

1. Mixing The raw materials are blended with various additives to enhance their properties. This could include compounds for increased strength, UV resistance, or improved flexibility.

2. Extrusion The mixed materials are then fed into an extruder, where they are heated and shaped into the desired hose profile. This step is critical, as it determines the internal diameter and wall thickness of the hose, both essential for determining its pressure ratings and overall performance.

3. Curing Curing, or vulcanization, is the process of cross-linking the rubber molecules to enhance the hose's elasticity and strength. This is typically done in a controlled environment where temperature and pressure are carefully monitored.

4. Quality Assurance After curing, the hoses undergo rigorous testing to ensure they meet industry standards. This includes pressure testing, flexibility tests, and checks for leaks or defects.

1/4 3/8 air hose factory

6. Packaging and Distribution Finally, the finished products are packaged and prepared for distribution to various markets and industries.

Quality Control in Air Hose Manufacturing

Given the critical role air hoses play in industrial applications, quality control is paramount. Manufacturers adhere to strict industry standards to ensure that each product is reliable and safe for use in various environments. This includes compliance with certifications such as ISO 9001 and ASTM standards. Manufacturers often implement a multi-tiered quality control process, involving both automated inspections and manual checks at different stages of production.

Regular audits and reviews of the manufacturing processes are also conducted. This not only helps to identify potential areas for improvement but also ensures that any changes to materials or processes do not compromise the quality of the end product.

The Future of Air Hose Manufacturing

The future of air hose manufacturing appears promising, driven by technological advancements and increasing demand for automation across industries. As manufacturing technologies evolve, manufacturers are exploring new materials that offer enhanced properties, such as lightweight alternatives that do not sacrifice durability or flexibility. Additionally, the integration of smart technologies into manufacturing processes is becoming more prevalent.

The growing emphasis on sustainability is another key trend shaping the future of air hose manufacturing. Many companies are now looking into eco-friendly materials and processes that minimize environmental impact. This includes recycling initiatives and the development of biodegradable options, reflecting the industry's commitment to sustainable practices.

Lastly, as industries continue to grow and change, the need for customized solutions is on the rise. Manufacturers are increasingly offering a variety of hoses tailored to specific applications, enabling customers to optimize their pneumatic systems for efficiency and performance.

Conclusion

Air hose manufacturing is a vital sector of the industrial landscape, ensuring that essential pneumatic systems function reliably and efficiently. With a strong focus on quality control, technological advancements, and a commitment to sustainability, the industry is poised for growth and transformation. As manufacturers continue to innovate and adapt to changing market demands, the future of air hose production looks bright, promising enhanced performance and reliability for years to come.

-

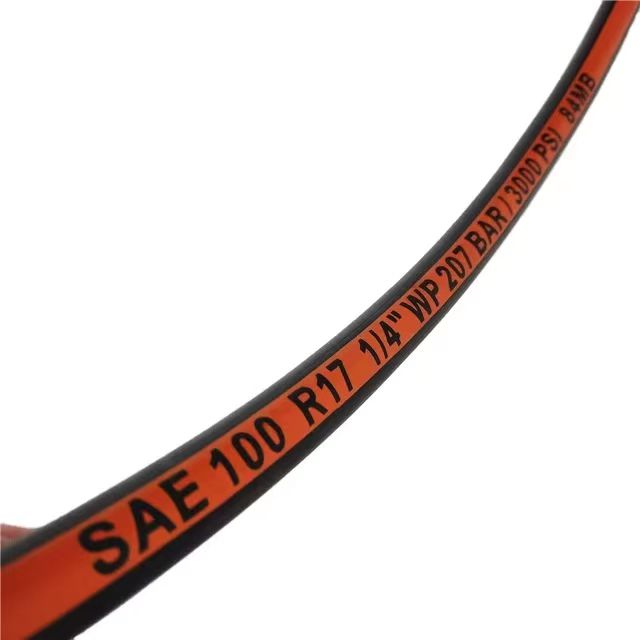

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025