335345435

ส.ค. . 07, 2024 18:10 Back to list

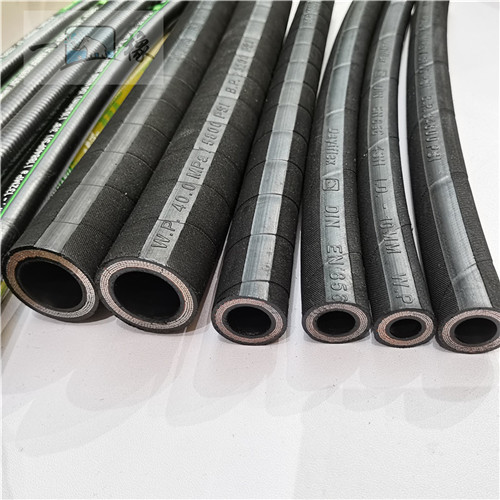

High-Quality Wrapped Steel Wire Spiral Hydraulic Hose Manufacturing in China for All Applications

China Wrapped Cover Steel Wire Spiral Hydraulic Hose Factory A Leader in Innovation and Quality

In the dynamic world of hydraulic technologies, the importance of reliable and high-performance hoses cannot be overstated. Among the many manufacturers operating in this field, China has established itself as a global hub for the production of wrapped cover steel wire spiral hydraulic hoses. These hoses are vital for various industrial applications, including construction, agriculture, and manufacturing, providing the necessary strength and flexibility to handle high-pressure scenarios.

Understanding Hydraulic Hoses

Hydraulic hoses are essential components that transport fluids under pressure. They are designed to withstand extreme conditions, including high pressure, temperature variations, and abrasive environments. A steel wire spiral hydraulic hose features steel wires embedded in the hose structure, which reinforces the hose and enables it to endure high-pressure systems. The wrapped cover provides additional protection against external abrasions and influences, ensuring longevity and reliable performance.

The Manufacturing Process

The manufacturing process of wrapped cover steel wire spiral hydraulic hoses is complex and requires advanced technology and skilled labor. It begins with the selection of high-quality raw materials, including synthetic rubber and steel wires. The hoses are constructed using a spiral winding technique, where wires are twisted and wrapped around the hose to create multiple layers of reinforcement. Once the hose is formed, a protective outer layer is added, often featuring a wrapped surface to enhance durability.

China's factories are equipped with state-of-the-art machinery that allows for precision manufacturing processes. Automation and robotics improve production efficiency, reduce waste, and ensure consistency in product quality. Manufacturers follow strict quality control procedures, including pressure testing and material inspections, guaranteeing that each hose meets international standards.

china wrapped cover steel wire spiral hydraulic hose factory

Commitment to Quality

In an era where reliability is paramount, Chinese manufacturers focus on providing high-quality hydraulic hoses. Leading factories invest in research and development to innovate and enhance their product offerings continuously. They strive to meet the diverse needs of clients across various sectors, ensuring that their products can withstand the specific challenges posed by different industries.

Furthermore, numerous manufacturers in China have attained international certifications, signifying compliance with global safety and performance standards. This commitment to quality has propelled Chinese wrapped cover steel wire spiral hydraulic hoses into international markets, making them a preferred choice for many companies worldwide.

Environmental Considerations

As environmental sustainability increasingly becomes a priority for manufacturers globally, Chinese hose factories are adopting eco-friendly practices. Efforts include optimizing production processes to reduce waste, using recyclable materials, and implementing efficient energy use strategies. These initiatives align with global trends toward sustainable manufacturing, allowing companies to appeal to a wider audience that values corporate social responsibility.

Conclusion

China's wrapped cover steel wire spiral hydraulic hose factories represent a convergence of innovation, quality, and sustainability. By utilizing advanced manufacturing techniques and adhering to strict quality guidelines, these factories produce hoses that meet the rigorous demands of various industries. As they continue to grow and expand their reach in international markets, their commitment to excellence ensures that they remain at the forefront of the hydraulic hose industry. Hydraulics, being the backbone of many industrial operations, are in good hands with the ongoing advancements made by these manufacturers.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025