335345435

พ.ย. . 02, 2024 02:59 Back to list

four wire spiral high pressure hydraulic hose factories

Four-Wire Spiral High Pressure Hydraulic Hose A Comprehensive Overview

In the realm of industrial machinery and equipment, high-pressure hydraulic hoses play a crucial role in ensuring efficiency, safety, and reliability. Among the various types of hydraulic hoses, the four-wire spiral high-pressure hydraulic hose stands out for its superior strength and durability. This article delves into the characteristics, advantages, and production processes associated with these hoses, shedding light on the factories that specialize in their manufacturing.

Characteristics of Four-Wire Spiral Hoses

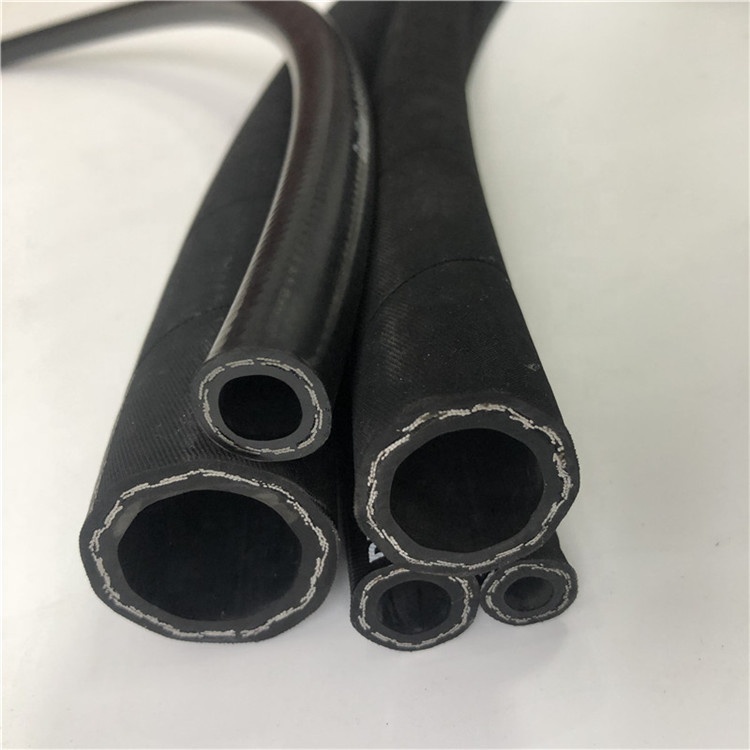

Four-wire spiral hydraulic hoses are designed to operate under extreme pressures, often exceeding 4,000 psi. They are constructed with four layers of wire reinforcement spiraled around the inner rubber tube, which provides exceptional tensile strength and resistance to deformation. This unique construction makes them particularly suitable for high-pressure applications in industries such as construction, mining, oil and gas, and manufacturing.

The inner tube is typically made from synthetic rubber, designed to handle a wide range of fluids, including hydraulic oil, water, and various chemicals. The outer cover is also made from durable materials, offering protection against abrasion, UV rays, and other environmental factors, which is critical for longevity and performance in rugged conditions.

Advantages of Four-Wire Spiral Hydraulic Hoses

four wire spiral high pressure hydraulic hose factories

One of the primary advantages of using four-wire spiral hydraulic hoses is their ability to withstand high pressure and impulse fatigue. This makes them ideal for applications that require consistent pressure and reliability over time. Moreover, their flexibility allows for easier routing and handling, essential in complex machinery environments.

Another important aspect is their compatibility with a variety of fittings and adapters, which enhances their versatility in different hydraulic systems. This adaptability, combined with their high-pressure resistance, means that four-wire spiral hoses can be used in numerous applications, ranging from agricultural machinery to aerospace systems.

Manufacturing Process and Factories

The production of four-wire spiral hydraulic hoses involves several stages, including material selection, wire placement, and curing. Factories dedicated to this manufacturing process typically employ advanced machinery to ensure precision and quality. The wire is carefully wound around the inner tube at specific angles to optimize performance and strength.

Quality control is paramount in the production of hydraulic hoses. Factories undergo rigorous testing to ensure that each hose meets industry standards and can withstand the intended operational pressures. Certifications from organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) are commonly sought to ensure product reliability.

In conclusion, four-wire spiral high-pressure hydraulic hoses represent a vital component in modern industrial applications. Their robust construction, coupled with the advanced manufacturing processes employed by specialized factories, ensures they provide the reliability and performance essential for high-pressure hydraulic systems. As industries continue to evolve, these hoses will play an increasingly important role in driving technological advancements and operational efficiency.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025