335345435

ธ.ค. . 05, 2024 16:54 Back to list

High Pressure Hydraulic Hose with One Wire Braid from China Factories for Quality Assurance

The Emergence of One Wire Braided High Pressure Hydraulic Hoses in China

In the past few decades, China has emerged as a global powerhouse in manufacturing, particularly in the field of hydraulic components. Among these, high-pressure hydraulic hoses have gained significant attention, especially the one wire braided variety. These hoses are essential in various industries, including construction, automotive, and manufacturing, providing reliable fluid transfer under high-pressure conditions. This article explores the production processes, applications, and advantages of one wire braided high-pressure hydraulic hoses in China.

Understanding One Wire Braided High Pressure Hydraulic Hoses

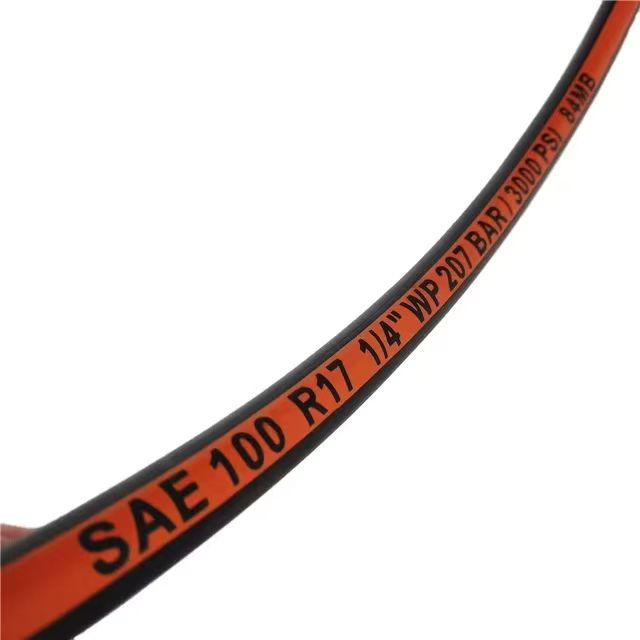

One wire braided high-pressure hydraulic hoses are designed to withstand high internal pressures while maintaining flexibility and durability. They consist of a synthetic rubber tube, one layer of steel wire braid, and an outer cover that protects the hose from environmental damage. The wire braid provides the necessary strength to handle high pressures, making these hoses suitable for applications ranging from automotive systems to industrial hydraulic equipment.

The Manufacturing Process

The production of one wire braided hydraulic hoses in China involves several key steps. The process begins with the preparation of high-quality synthetic rubber compounds that will form the inner lining of the hose. Manufacturers prioritize materials that offer excellent resistance to wear, oil, and temperature variations.

After preparing the rubber, the next step involves forming the tube around a mandrel. Once the inner tube is created, the steel wire is braided around it. This is a crucial step, as the quality of the braiding directly impacts the hose's performance. Automated braiding machines are often used to ensure uniformity and precision in the wire arrangement. Following this, the outer cover is applied, which may involve a variety of materials to enhance protection against abrasion, UV rays, and chemical exposure.

Finally, the hose undergoes rigorous testing for integrity, flexibility, and pressure resistance

. This quality assurance step is vital, considering that these hoses are often used in critical applications where safety and reliability are paramount.Applications of One Wire Braided Hoses

china one wire braided high pressure hydraulic hose factories

One wire braided hydraulic hoses are versatile and can be used in many applications. They are commonly found in hydraulic systems of construction machinery, excavators, and forklifts, where high-pressure fluid transfer is essential. In the automotive industry, these hoses are critical for steering systems and braking systems, providing necessary pressure and flexibility.

Other applications include agricultural machinery, mining equipment, and various manufacturing processes. The adaptability of one wire braided hydraulic hoses makes them a popular choice across diverse sectors, ensuring efficient performance in different environmental conditions.

Advantages of Sourcing from Chinese Factories

China's advantages in manufacturing one wire braided high-pressure hydraulic hoses are manifold. Firstly, the country boasts a well-established supply chain for raw materials, enabling manufacturers to keep production costs low while maintaining high-quality standards.

Secondly, the scale of production allows for economies of scale, resulting in more competitive pricing in the global market. Chinese manufacturers invest substantially in advanced technologies and training, ensuring that their production processes meet international standards.

Moreover, China has cultivated a skilled workforce adept at hydraulic system technologies. This expertise contributes to the innovation and continuous improvement seen in the design and functionality of hydraulic hoses.

Conclusion

The rise of one wire braided high-pressure hydraulic hoses in China's manufacturing sector reflects the country's robust industrial capabilities and commitment to quality. As industries worldwide continue to demand reliable and efficient hydraulic solutions, Chinese factories are poised to remain leaders in this niche market. With ongoing advancements in technology and production techniques, the future of one wire braided hydraulic hoses appears bright, promising improvements in performance and durability for applications across various sectors.

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025