335345435

ม.ค. . 14, 2025 12:32 Back to list

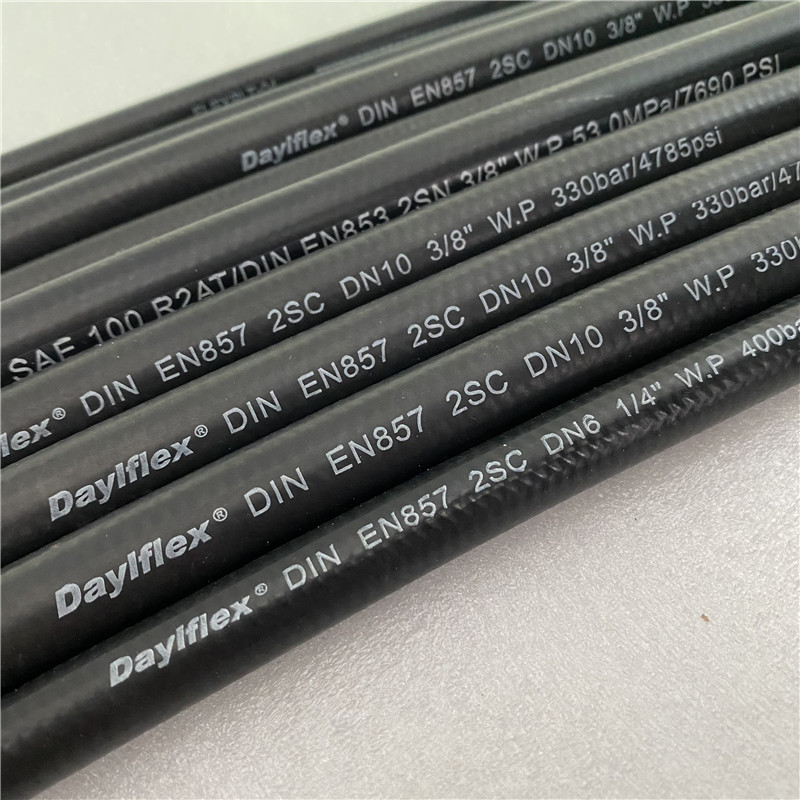

16mm hydraulic hose

A 16mm hydraulic hose is an essential component in various industrial and automotive applications, transmitting hydraulic fluid to power machinery and vehicles. Its reliability and effectiveness are key to maintaining operational efficiency and safety. Here’s a comprehensive exploration into the 16mm hydraulic hoses, providing valuable insights for users seeking the best solutions for their needs.

Safety and Maintenance Considerations A fundamental aspect of using hydraulic hoses is ensuring their safety and regular maintenance. Poorly maintained hoses can result in fluid leaks, leading to system failures or even accidents. Regular inspection for signs of wear, such as cracks or leaks, is crucial. Employing proper installation techniques also extends the hose's lifespan, reducing the frequency of replacements and thereby saving on costs in the long run. Compliance and Standards Reliable manufacturers adhere to industrial standards, ensuring their hoses meet quality and safety benchmarks. Standards like SAE (Society of Automotive Engineers) or ISO (International Organization for Standardization) highlight the hose's capability to perform under specified conditions. Purchasing hoses that meet these standards guarantees a level of trustworthiness and authority in their performance. Innovation in Material Technology The field of hydraulic hoses continuously evolves, with innovations in materials enhancing hose capabilities. Latest developments include the use of polyurethane, which offers lightweight yet durable properties compared to traditional rubber. This innovation not only improves the hose's operational efficiency but also reduces environmental impact, aligning with eco-friendly industrial practices. In conclusion, understanding the intricacies of 16mm hydraulic hoses empowers users to make informed decisions, ensuring their systems are efficient, safe, and durable. By considering factors like durability, technical specifications, safety, compliance, and technological advancements, businesses can significantly enhance their operational efficiency and reduce downtime. As industries progress, the role of well-selected hydraulic hoses becomes even more critical in supporting advanced machinery and robust mechanical systems.

Safety and Maintenance Considerations A fundamental aspect of using hydraulic hoses is ensuring their safety and regular maintenance. Poorly maintained hoses can result in fluid leaks, leading to system failures or even accidents. Regular inspection for signs of wear, such as cracks or leaks, is crucial. Employing proper installation techniques also extends the hose's lifespan, reducing the frequency of replacements and thereby saving on costs in the long run. Compliance and Standards Reliable manufacturers adhere to industrial standards, ensuring their hoses meet quality and safety benchmarks. Standards like SAE (Society of Automotive Engineers) or ISO (International Organization for Standardization) highlight the hose's capability to perform under specified conditions. Purchasing hoses that meet these standards guarantees a level of trustworthiness and authority in their performance. Innovation in Material Technology The field of hydraulic hoses continuously evolves, with innovations in materials enhancing hose capabilities. Latest developments include the use of polyurethane, which offers lightweight yet durable properties compared to traditional rubber. This innovation not only improves the hose's operational efficiency but also reduces environmental impact, aligning with eco-friendly industrial practices. In conclusion, understanding the intricacies of 16mm hydraulic hoses empowers users to make informed decisions, ensuring their systems are efficient, safe, and durable. By considering factors like durability, technical specifications, safety, compliance, and technological advancements, businesses can significantly enhance their operational efficiency and reduce downtime. As industries progress, the role of well-selected hydraulic hoses becomes even more critical in supporting advanced machinery and robust mechanical systems.

Share

Latest news

-

Distribution PTFE Hose: Flexible, Chemical-Resistant Solutions

NewsAug.26,2025

-

SAE 100 R1AT Hydraulic Hose: Smooth, Wrapped & Colourful

NewsAug.25,2025

-

Premium Distribution PTFE Hose | Flexible & Stainless Braided

NewsAug.23,2025

-

Premium Distribution PTFE Hose: Flexible & Durable Solutions

NewsAug.22,2025

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025